10 Reasons Every Factory Needs a Plastic Recycling Machine

In the modern manufacturing industry, sustainability and cost-efficiency are no longer optional—they’re essential. Every factory, regardless of its size or sector, generates a certain amount of plastic waste. This waste can either become a costly disposal problem or be transformed into a valuable resource with the help of a plastic recycling machine. From reducing environmental impact to boosting profitability, the benefits are clear.

Whether you are running a large-scale production facility or a smaller unit, integrating a plastic granulator machine, waste plastic recycling machine, or small plastic recycling machine into your operations can make a remarkable difference. Here’s why every manufacturing unit should consider investing in one.

1. Reduces Waste Disposal Costs

Factories that produce plastic waste often spend significant amounts on waste disposal services. By installing a plastic recycling machine, companies can drastically cut these costs. Instead of paying to have plastic waste hauled away, the waste can be shredded, granulated, or pulverized on-site and reused in production. This cost-saving benefit directly impacts the bottom line while supporting sustainable manufacturing.

2. Turns Waste into Profit

One of the most overlooked advantages is that recycled plastic can be sold as raw material to other manufacturers. Using a plastic granulator machine, waste is converted into uniform-sized granules that have commercial value. This not only offsets production costs but can even create an additional revenue stream for the business.

3. Improves Raw Material Utilization

Factories often discard scrap plastic that still has potential value. A waste plastic recycling machine enables companies to reprocess production offcuts, rejected parts, and damaged goods into reusable materials. This improves material efficiency, reduces dependency on virgin plastic, and helps maintain a more stable production cost structure even when raw material prices fluctuate.

4. Supports Environmental Responsibility

With growing awareness about plastic pollution, customers and stakeholders expect manufacturers to act responsibly. A Plastic Recycling Machine in India not only helps companies comply with environmental regulations but also strengthens their brand image. When customers see that a company takes recycling seriously, it builds trust and long-term loyalty.

5. Meets Government Regulations

Many regions in India and across the globe now enforce strict guidelines for waste management. Failing to comply can lead to hefty fines and legal troubles. Investing in a Plastic Recycling Machine Manufacturer in India ensures that factories meet these standards effortlessly. It’s not just a matter of compliance—it’s about future-proofing the business.

6. Enhances Production Flexibility

Recycling machines make it possible for manufacturers to experiment with new product lines by using recycled plastic in their production process. This opens opportunities to produce cost-effective products for markets that are price-sensitive. For example, a small plastic recycling machine can handle niche production runs without requiring a major investment.

7. Reduces Carbon Footprint

Producing new plastic from raw petroleum-based resources consumes a lot of energy and contributes to greenhouse gas emissions. By using recycled plastic, factories can significantly cut down their carbon footprint. This makes them more competitive in industries where sustainability is becoming a key purchasing factor for customers.

8. Saves Space in the Factory

Plastic waste can take up a lot of valuable storage space. Over time, piles of unused plastic parts, scrap, and packaging materials can clutter the production area, affecting workflow efficiency. A plastic granulator machine or waste plastic recycling machine processes this waste into compact granules that are easier to store or transport, freeing up space for more productive uses.

9. Delivers a Quick Return on Investment

The plastic recycling machine price varies based on capacity and features, but in most cases, the machine pays for itself quickly through savings in raw material purchases, waste disposal, and additional sales of recycled plastic. For many factories, the ROI period is surprisingly short—sometimes less than a year.

10. Strengthens Brand Competitiveness

In competitive markets, being environmentally responsible can be a key differentiator. When you advertise that your products are made with recycled plastic using advanced recycling equipment, it positions your brand as innovative, eco-friendly, and socially responsible. This can help win contracts, attract new customers, and improve overall market perception.

Why Choose Invoit Plast Machinery Pvt. Ltd.?

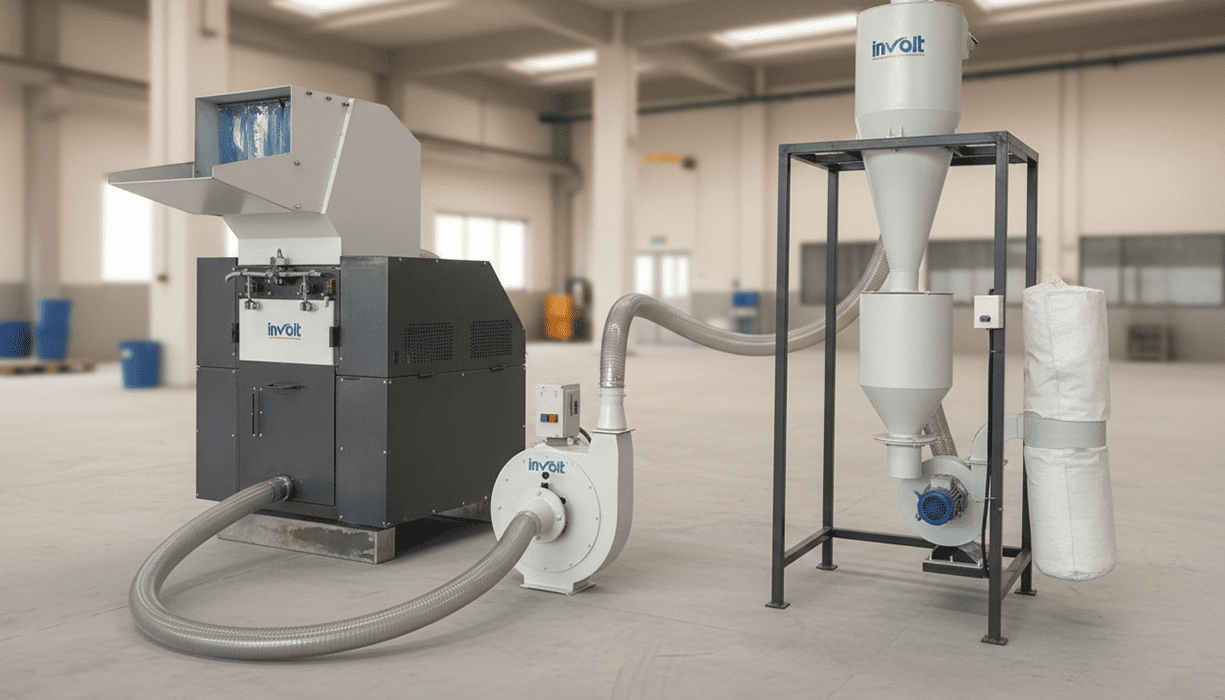

When it comes to investing in high-quality recycling equipment, choosing the right partner is critical. Invoit Plast Machinery Pvt. Ltd. is widely recognized as the Best Plastic Recycling Machine Manufacturer in India, offering a complete range of solutions including plastic granulator machines, waste plastic recycling machines, and small plastic recycling machines.

Their machines are engineered for maximum efficiency, durability, and cost-effectiveness. Whether you are looking for a compact model for a smaller setup or a high-capacity unit for large-scale operations, Invoit Plast has the expertise to deliver tailored solutions at competitive prices.

Final Thoughts

A Plastic Recycling Machine in India is no longer a luxury—it’s an essential piece of equipment for any factory committed to reducing costs, improving efficiency, and meeting environmental responsibilities. By turning waste into profit, reducing dependency on virgin materials, and ensuring compliance with regulations, a recycling machine provides benefits that go far beyond cost savings.

Whether you’re concerned about plastic recycling machine price, operational efficiency, or brand sustainability, the long-term advantages far outweigh the initial investment. Partnering with a trusted name like Invoit Plast Machinery Pvt. Ltd. ensures you get the best technology, support, and value for your money.

In today’s fast-changing industrial landscape, adopting plastic recycling technology is one of the smartest moves a factory can make—for profitability, for sustainability, and for the planet.

FAQs

A plastic recycling machine processes scrap, waste, and defective plastic products into reusable raw material. In factories, it helps reduce waste disposal costs, improve raw material utilization, and support sustainable manufacturing.

A plastic granulator machine cuts and grinds waste plastic into uniform granules, which can be reused in production or sold to other manufacturers. It is an essential part of the recycling process for many industries.

The plastic recycling machine price depends on factors like capacity, automation level, and material compatibility. Basic models may be more affordable for small units, while high-capacity industrial machines cost more but deliver faster ROI.

Yes. A small plastic recycling machine is ideal for small-scale or specialized production units. It’s perfect for factories that need a compact, affordable, and efficient recycling solution without compromising on quality.

A waste plastic recycling machine helps convert plastic waste into valuable raw material, reduces landfill contributions, and lowers manufacturing costs. It also ensures compliance with environmental regulations in India.

Invoit Plast Machinery Pvt. Ltd. is recognized as one of the Best Plastic Recycling Machine Manufacturers in India, offering high-quality, durable, and cost-efficient solutions for both small and large factories.

Absolutely. With rising raw material costs and strict environmental laws, investing in a Plastic Recycling Machine in India not only saves money but also boosts sustainability and market competitiveness.