Plastic Crusher Machine

Plastic Crusher Machine

In today’s environmentally conscious world, plastic crusher machine have become indispensable tools in plastic recycling, waste management, and industrial plastic processing. These powerful machines are designed to break down large plastic materials into smaller, reusable pieces, facilitating efficient recycling and reducing the ecological impact of plastic waste.

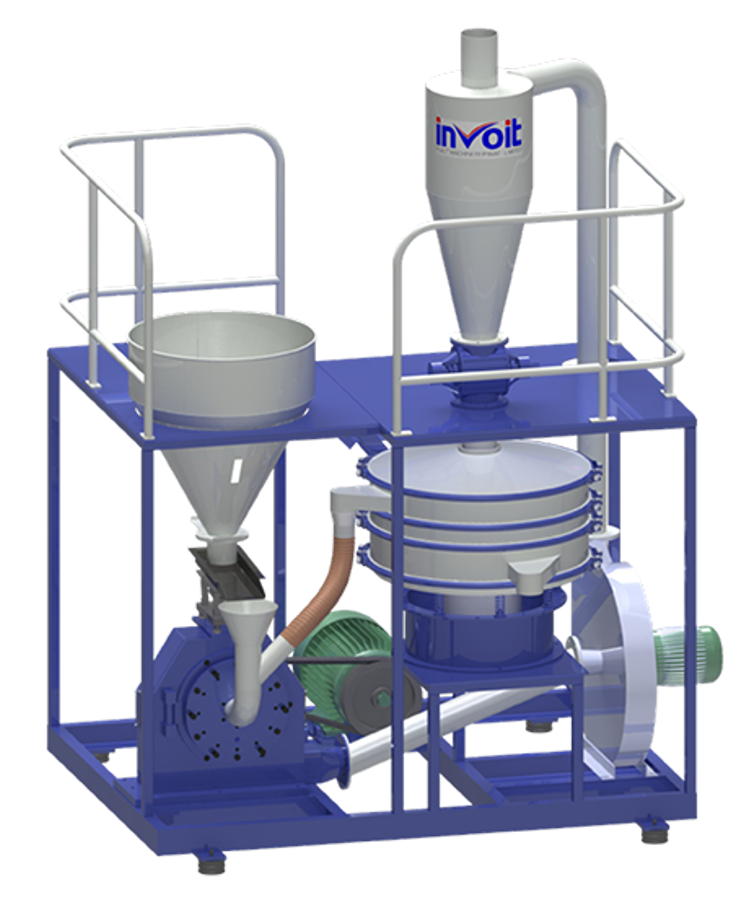

Invoit Plast Machinery PVT Ltd., a pioneering plastic crusher machine manufacturer in Ahmedabad, India, is at the forefront of providing innovative and high-quality plastic recycling machinery. With years of industry expertise, the company has established a solid reputation for delivering robust and efficient machines tailored for various industrial applications.

Working Principle of a Plastic Crusher Machine

Understanding how a plastic crusher machine works is essential for optimizing its usage and output. The machine operates through a systematic mechanism involving several core processes:

- Material Feeding: Plastic scrap is fed into the crusher through a hopper or conveyor belt.

- Rotating Blades: High-speed, sharp rotating blades shred the plastic material into smaller pieces.

- Crushing Process: The plastic undergoes multiple rounds of cutting and grinding until it reaches the desired size.

- Screening Mesh: The machine uses mesh filters or screens to ensure only particles of specific sizes pass through.

- Output: The crushed plastic is collected for further processing, such as extrusion or granulation.

This efficient plastic crushing process ensures high throughput, uniform particle size, and minimal energy consumption. Invoit Plast’s machines are designed with cutting-edge technology to enhance the plastic shredder machine working mechanism for optimal performance.

Types of Plastic Crusher Machine

Invoit Plast Machinery PVT Ltd. offers a wide range of plastic crusher machine to cater to different recycling and industrial requirements. Here are the major types available:

Plastic Granulators

Plastic Pulverizers

Plastic Scrap Grinder

1. Plastic Granulators

Ideal for small to medium-scale waste processing, these machines offer excellent precision and are suitable for softer plastic materials. Plastic granulator machine are used extensively in packaging, automotive, and consumer goods industries.

2. Plastic Pulverizers

These machine are designed to grind plastic into a fine powder. Suitable for materials like PVC, LLDPE, and HDPE, Plastic Pulverizer Machine are vital in producing powder for film manufacturing, coating, and rotomolding.

- PVC Pulverizer Machine: Specially designed for rigid PVC material.

- LLDPE Pulverizer Machine: Perfect for linear low-density polyethylene powder.

3. Plastic Scrap Grinder (Exclusive from Invoit Plast)

Invoit Plast’s Plastic Scrap Grinder is an innovative addition engineered for heavy-duty grinding of large volumes of plastic scrap. With a focus on efficiency, durability, and ease of maintenance, this machine ensures continuous operation and high output in industrial settings.

Applications of Plastic Crusher Machines

The versatility of plastic crusher machine makes them a key component across various industries. Below are some of the major application areas:

- Plastic Recycling Plants: Used to convert post-consumer or post-industrial plastic waste into reusable material.

- Manufacturing Industries: Helps in reprocessing defective parts and sprues from plastic molding operations.

- Plastic Product Factories: Facilitates the reuse of rejected parts and surplus materials.

- Waste Management Facilities: Assists in the efficient sorting, shredding, and processing of mixed plastic waste.

The output from these machines can be utilized to create plastic granules, pellets, or even powder, which then becomes the raw material for producing new plastic products.

Invoit Plast Machinery PVT Ltd. contributes to both local and global waste management projects by supplying high-performance plastic crushers that meet international quality standards.

Benefits of Using a Plastic Crusher Machine

The adoption of plastic crusher machine brings multiple benefits—both economic and environmental:

1. Cost-Efficiency

Recycling plastic in-house reduces the cost of purchasing raw materials and disposal charges, enhancing profit margins.

2. Waste Reduction

Crushing plastic waste minimizes the volume and makes handling, storage, and transportation more efficient.

3. Environmental Sustainability

By diverting plastic waste from landfills, these machines support eco-friendly practices and contribute to a sustainable future.

4. Energy-Efficient Models

Invoit Plast Machinery PVT Ltd. offers energy-efficient machines designed to reduce power consumption while maintaining high productivity.

5. Space-Saving

Compact models are available for space-constrained environments, making them ideal for small-scale industries and workshops.

Maintenance Tips for Plastic Crusher Machine

Regular maintenance is critical to ensuring the optimal performance and longevity of plastic crusher machines. Here are essential maintenance tips:

- Blade Sharpening: Dull blades reduce efficiency. Sharpen blades regularly or replace them when worn out.

- Lubrication: Keep all moving parts well-lubricated to prevent friction and wear.

- Screen Inspection: Regularly inspect and clean the mesh screens to avoid clogging and ensure uniform output.

- Motor and Bearing Checks: Monitor motor health and bearings for signs of overheating or excessive vibration.

- Electrical Component Testing: Ensure that all electrical controls and sensors are functioning properly.

Invoit Plast Machinery PVT Ltd. offers dedicated customer support and maintenance services to help clients keep their machines in top condition.

Safety Considerations When Operating a Plastic Crusher

Safety is a top priority when operating industrial plastic crusher machine. Follow these safety tips to ensure safe operation:

- Wear Protective Gear: Operators should always wear gloves, goggles, and protective clothing.

- Proper Grounding: Machines should be grounded correctly to avoid electrical hazards.

- Avoid Overloading: Feed material gradually and avoid inserting oversized or non-plastic materials.

- Emergency Stop Systems: Use machines equipped with emergency stop buttons for quick halts.

- Routine Safety Checks: Inspect the machine for any loose or damaged parts before operation.

Why Choose Invoit Plast Machinery PVT Ltd.

With decades of industry experience, Invoit Plast Machinery PVT Ltd. is the go-to brand for anyone seeking a reliable plastic crusher machine for recycling in India. Combining technological excellence with a customer-centric approach, Invoit Plast has successfully served clients across Ahmedabad, India, and various international markets.

What Sets Invoit Plast Apart:

- Precision Engineering: Machines built with the latest technology and robust materials.

- Customization Options: Solutions tailored to specific industrial requirements.

- Sustainability Focus: All products promote eco-friendly plastic recycling.

- Global Reach: Trusted by industries in India and abroad for quality and durability.

- After-Sales Support: Comprehensive maintenance, training, and spare parts availability.

By choosing Invoit Plast, you invest in sustainable plastic waste management in Ahmedabad and beyond, contributing to a cleaner, greener future.

Specification

| Sr. No. | Models | Disc. Dia | Main Motor | Output (Kg./hr) | Floor Space (mm) | Vibro inch | Pump (HP) | ||

| Length | Width | Height | |||||||

| 1 | PK-50 | 250 | 15 | 45-55 | 2000 | 1400 | 3000 | 26” | 0.5 |

| 2 | PK-80 | 300 | 20 | 60-80 | 2100 | 1400 | 3100 | 26” | 0.5 |

| 3 | PK-110 | 300 | 30 | 110-115 | 2100 | 1400 | 3100 | 32” | 0.5 |

| 4 | PK-160 | 400 | 40 | 155-170 | 2400 | 1600 | 3500 | 39” | 0.5 |

| 5 | PK-200 | 400 | 50 | 185-220 | 2400 | 1600 | 3500 | 48” | 1.0 |

| 6 | PK-250 | 600 | 60 | 240-260 | 3500 | 1850 | 4000 | 48” | 1.0 |

| 7 | PK-300 | 600 | 75 | 300-325 | 3500 | 1850 | 4000 | 60” | 1.0 |