Top Applications of Spring Conveyor in Plastic and Recycling Industries

In modern plastic processing and recycling operations, the efficiency of material handling systems directly impacts overall productivity. Among the many tools used in these operations, Spring Conveyors—also known as flexible spiral conveyors—stand out for their simplicity, space-saving design, and ability to handle bulk materials with minimal energy consumption.

These conveyors are highly adaptable and are increasingly becoming the preferred choice in plastic and recycling plants across India and globally. In this blog, we will explore the top applications of spring conveyors in the plastic and recycling industries, the benefits they offer, and why choosing the right manufacturer matters.

Understanding the Role of Spring Conveyors

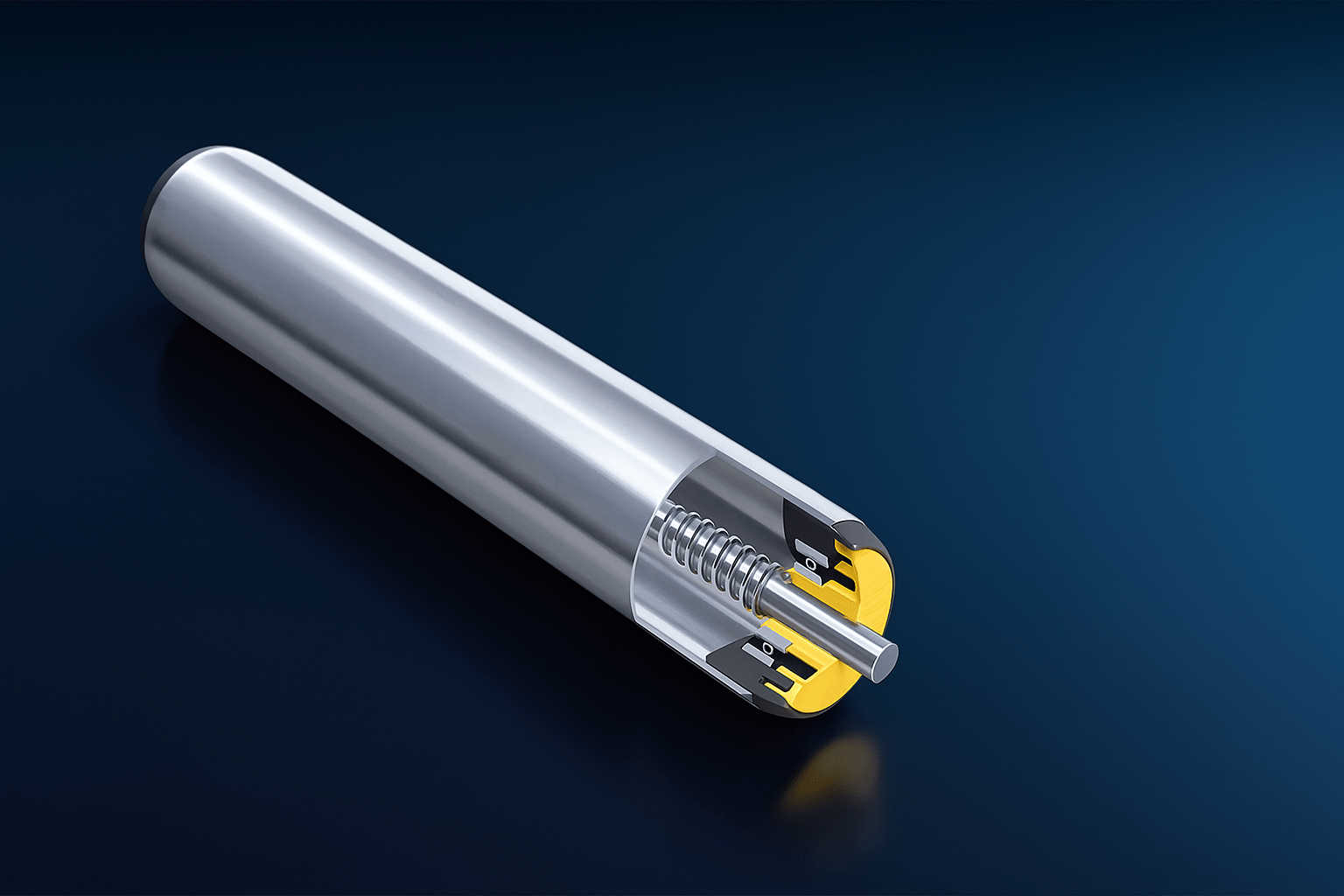

A spring conveyor is a type of mechanical conveyor that uses a rotating helical spring inside a tube to transport material. The spring—usually made of stainless steel or high-grade steel—is connected to a motor that rotates it, moving material through the enclosed pipe from the feed end to the discharge point.

This simple yet effective conveying mechanism offers a dust-free, compact, and flexible solution for transporting powders, granules, pellets, and other bulk materials. In plastic and recycling environments where cleanliness, automation, and reduced spillage are essential, spring conveyors are invaluable.

Material Feeding in Plastic Extrusion

In plastic extrusion processes, maintaining a steady and controlled feed of raw materials such as plastic granules or powders is critical. Spring conveyors are often installed between material storage silos or bins and the hopper of the extruder machine.

They offer a continuous and reliable material feed, reducing manual handling and minimizing downtime. Unlike pneumatic conveyors, they do not require compressed air, which makes them energy-efficient. Their enclosed design prevents contamination, especially when working with food-grade or medical-grade plastic compounds.

Transporting Regrind Material in Recycling Plants

One of the key applications of spring conveyors in the recycling sector is the transport of regrind plastic materials from the granulator or shredder to the next processing stage.

In recycling facilities, where space is often limited and materials need to be transported vertically or around obstacles, spring conveyors provide an adaptable and compact conveying solution. The flexibility of the spring allows easy routing and installation, especially in retrofitted plants.

Moreover, their gentle conveying motion ensures that the recycled plastic particles do not degrade further due to excessive heat or friction during transport.

Feeding Pulverizing Machines with Fine Plastic Powder

Pulverizing machines that reduce plastic into ultra-fine powder require consistent feeding to maintain efficiency and avoid overloading or underfeeding. Spring conveyors are ideal for this application, particularly because of their low-speed, gentle conveying motion which reduces dust generation and preserves powder quality.

Their enclosed design also makes them suitable for transporting fine, lightweight powders that may otherwise escape or become airborne. This is especially useful in applications involving PVC powder, LDPE, or LLDPE materials.

Blending System Integration for Plastic Compounds

When working with multiple plastic resins or additives, a spring conveyor can be used to feed blending systems that require input from various sources. These systems ensure the correct mix of plastic material, color masterbatch, and other additives before being sent to an extruder or molding machine.

Spring conveyors provide automated batch feeding to mixing equipment, minimizing human error and labor while maintaining high throughput. Their ability to start and stop with minimal lag also improves process control in integrated plant systems.

Compact Vertical Lifting of Materials

In factories with limited floor space, vertical lifting of materials becomes crucial. Spring conveyors are particularly well-suited for lifting plastic pellets, chips, or powder from ground-level collection bins to higher-level hoppers or silos.

Thanks to their spiral design, they can achieve significant vertical conveying with minimal footprint. Unlike belt or chain conveyors, they do not require tensioning or large motors to operate, making them both cost-effective and maintenance-friendly.

This vertical conveying is a frequent requirement in injection molding and recycling setups, where different machines operate at varied heights and locations.

Dust-Free Conveying of Lightweight Plastic Materials

In many plastic processing environments, maintaining air quality and reducing dust is essential—especially when working with lightweight materials like foam, film flakes, or fine powders.

Spring conveyors are enclosed and operate at lower speeds, which minimizes airborne dust particles. This feature is highly beneficial in recycling centers that process mixed plastic waste or biodegradable materials, where dust contamination could affect product quality or machine performance.

Additionally, the dust-free operation helps meet safety and hygiene standards, especially for companies working with food-grade or pharmaceutical plastics.

Controlled Discharge and Metering in Extrusion and Molding

Another important application of spring conveyors in the plastic industry is in controlled material metering. Whether it’s feeding small batches into an injection molding machine or dosing material into an extrusion line, precision in feeding rates is crucial to maintain consistency and product quality.

Spring conveyors can be equipped with sensors and variable speed drives to offer controlled discharge that aligns with the production line’s needs. This eliminates the chances of underfeeding or overfeeding, which could lead to material wastage or product defects.

Ideal for Harsh or Compact Environments

Spring conveyors are robust and can operate efficiently in harsh industrial environments, where moisture, heat, or corrosive particles might be present. This makes them ideal for post-consumer plastic recycling, where varying material types and contamination levels are common.

Also, due to their compact design and lack of complex mechanical parts like rollers or belts, they require less maintenance and occupy less space—perfect for compact factory floors or mobile recycling units.

Promoting Automation in Plastic Waste Management

In modern automated recycling systems, integration between machines is vital. Spring conveyors enable seamless inter-machine material flow, allowing fully automated recycling lines that can process plastic waste with little human intervention.

They can be connected with shredders, granulators, washing units, dryers, and extruders, ensuring a fully automated, closed-loop system. This contributes to increased efficiency, better resource utilization, and ultimately, lower operational costs.

Why Choose Invoit Plast Machinery PVT. LTD. for Spring Conveyors?

When it comes to investing in durable, efficient, and cost-effective spring conveyors, the choice of manufacturer makes a big difference.

Invoit Plast Machinery PVT. LTD. is recognized as the Best Spring Conveyor manufacturer in India, offering high-quality, performance-driven conveying solutions tailored to plastic and recycling industry needs. Their machines are designed with precision engineering, robust materials, and customizable options to suit every factory setup.

With years of expertise in plastic processing equipment, Invoit Plast ensures top-tier quality, technical support, and on-time delivery, helping clients scale their operations confidently.

Final Thoughts

Spring conveyors have revolutionized the way plastic and recycling industries handle bulk materials. From precise feeding to vertical conveying, dust control, and automation integration, their applications are vast and growing.

Their compact footprint, energy efficiency, and versatility make them a must-have in any modern plastic processing or recycling plant. For businesses aiming to enhance their conveying systems, adopting spring conveyors is a smart, future-proof investment.

FAQs

A spring conveyor, also known as a flexible spiral conveyor, uses a rotating helical spring inside a tube to move bulk materials like plastic granules or powders from one point to another. The spring’s motion gently pushes materials through the tube, making it ideal for compact and enclosed conveying systems.

Spring conveyors are widely used in the plastic industry for feeding extruders, transporting regrind or recycled plastic, loading mixing systems, and lifting materials vertically into hoppers or silos. Their dust-free and flexible design makes them suitable for tight spaces and clean environments.

In recycling plants, spring conveyors transport shredded plastic, flakes, or powder between machines such as granulators, pulverizers, and extruders. Their ability to handle variable material shapes and densities makes them essential for seamless recycling operations.

Yes, spring conveyors are perfect for transporting fine plastic powders like PVC or LLDPE due to their enclosed design and gentle conveying motion. They reduce dust formation and material loss while ensuring consistent flow.

Invoit Plast Machinery PVT. LTD. is a trusted name in plastic processing equipment, offering high-performance, reliable, and customizable spring conveyor solutions. Their expertise, quality engineering, and after-sales support make them the top choice for industries across India.

Absolutely. Spring conveyors are compact and can be installed vertically or around obstacles, making them ideal for space-constrained environments in both plastic and recycling plants.

Yes, spring conveyors are compatible with automated systems. They can be integrated with sensors and variable speed drives to provide precise material flow control in automated plastic processing lines.

Spring conveyors can handle a wide range of materials, including plastic pellets, granules, regrind, flakes, powder, color masterbatch, and lightweight materials like film scrap or foam.

Spring conveyors don’t require compressed air, reducing energy costs. They are easier to maintain, cause less dust, and are better suited for gentle, enclosed, and short-distance conveying.

Yes, manufacturers like Invoit Plast Machinery provide customized spring conveyor systems based on your application needs—such as length, material type, output rate, and installation layout.