The Working Principle of High-Speed Mixer Machines Explained

In modern plastic processing and chemical industries, achieving uniform mixing in the shortest possible time is crucial. That’s where high-speed mixer machines play a pivotal role. Whether you’re blending PVC, color masterbatches, or other plastic resins, high-speed mixers help streamline your operations by ensuring homogeneous material preparation. But what exactly makes these machines so efficient? Let’s explore the working principle of high-speed mixer machines and understand why they’re considered indispensable in today’s manufacturing environment.

What is a High-Speed Mixer Machine?

A high-speed mixer machine is an industrial equipment primarily used to blend, homogenize, and prepare plastic raw materials, additives, or chemicals. The unique feature of this machine is its ability to operate at extremely high rotor speeds—often ranging between 1,200 to 3,000 RPM—allowing it to mix materials faster and more uniformly than conventional blenders.

These mixers are commonly used in plastic processing industries for mixing PVC resin with plasticizers, stabilizers, fillers, and lubricants before further processing in extrusion or molding machines. They are also used in pharmaceutical, food, and chemical industries.

Key Components of a High-Speed Mixer

Before diving into the working principle, it’s essential to understand the main components of a high-speed mixer:

- Mixing Vessel (Drum): Usually made of stainless steel to ensure durability and chemical resistance.

- Impeller or Rotor Blades: Rotates at high speed to create a vortex, lifting and circulating materials inside the drum.

- Motor and Gearbox: Provides the required torque and speed to the rotor.

- Discharge Unit: Facilitates easy removal of the mixed material.

- Control Panel: Manages operational parameters like speed, temperature, and time.

Why Frictional Heating Is Beneficial

The high-speed mixer operates on a centrifugal force mechanism. When the machine starts, the motor drives the impeller at a high rotational speed. This action generates a strong vortex within the mixing drum, pulling material from the center towards the walls and then lifting it upwards before it falls back. This cycle repeats rapidly, resulting in a turbulent mixing action that thoroughly blends all materials in a short time.

Here’s how the mixing process unfolds step-by-step:

Material Loading:

The raw materials—like plastic resins, pigments, stabilizers, and fillers—are loaded into the drum through a feed inlet.

Impeller Activation:

Once the machine is turned on, the motor starts the impeller rotation. Depending on the design, some machines use dual-speed settings for better control.

Creation of Vortex:

The rotating blades create a centrifugal force that lifts and disperses the material within the drum, forming a powerful vortex.

Shear and Friction:

Due to high-speed rotation, the materials rub against each other and the drum walls. This generates shear force and frictional heat, which helps in uniform mixing and even pre-heating of the mix.

Homogenization:

Within minutes, the materials are uniformly mixed and prepared for the next processing step, such as extrusion or molding.

Discharge:

The mixed material is discharged via an outlet, ready for immediate use or storage.

Why Frictional Heating Is Beneficial

One of the unique advantages of high-speed mixers is the frictional heat generated during the mixing process. This heat softens the plastic resins slightly, making it easier to absorb additives. This pre-heating reduces the load on extruders or molding machines and enhances the quality of the final product.

For example, in PVC processing, high-speed mixers not only mix the ingredients but also ensure that the PVC resin absorbs stabilizers and plasticizers more effectively, resulting in better product performance.

Benefits of Using High-Speed Mixer Machines

The working mechanism of high-speed mixer machines provides several operational and productivity benefits:

- Rapid Mixing: High RPM ensures fast and efficient mixing, saving valuable production time.

- Uniform Quality: Vortex mixing results in consistent blending of all components.

- Energy Efficiency: Quick processing leads to reduced power consumption per batch.

- Versatility: Suitable for a variety of materials including thermoplastics, elastomers, pigments, and additives.

- Pre-Heating Functionality: The heat generated during mixing aids in pre-conditioning the raw materials.

- Compact Design: High capacity can be achieved without large footprints.

Common Applications in Industry

High-speed mixers are widely used in:

- Plastic Processing Plants: For preparing PVC, HDPE, LDPE, and PP compounds.

- Masterbatch Manufacturing: Ensuring even dispersion of pigments and additives.

- Chemical Industry: For mixing powders, granules, and resin blends.

- Food Industry: In dry ingredient blending (though with different sanitary designs).

- Pharmaceutical Sector: For rapid blending of bulk powders.

Choosing the Right High-Speed Mixer for Your Application

Selecting the right mixer depends on your processing needs. Key factors include:

- Batch size requirements

- Type of material (powder, granule, pellet)

- Desired mixing time

- Temperature control needs

- Ease of cleaning and maintenance

It’s always recommended to consult with a reliable manufacturer who can understand your production challenges and recommend the best-suited model.

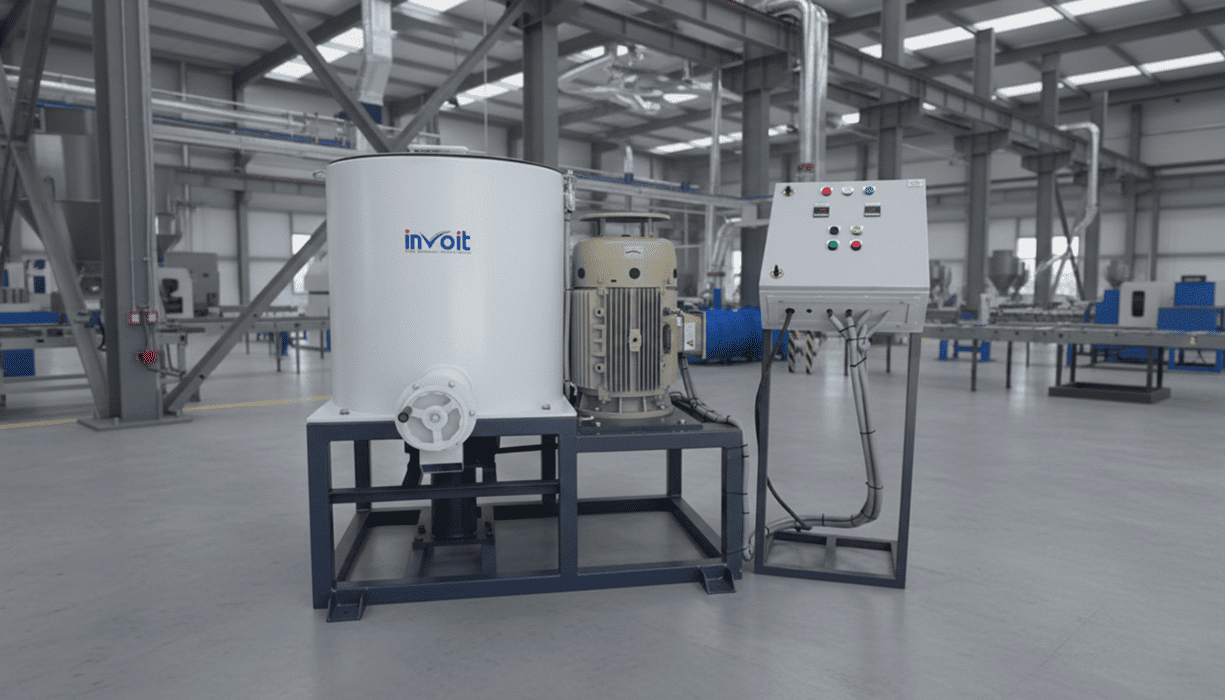

Why Choose Invoit Plast Machinery PVT Ltd?

When it comes to investing in reliable, efficient, and durable high-speed mixers, Invoit Plast Machinery PVT Ltd stands out as the Best High-Speed Mixer Manufacturer in India. With years of expertise in plastic processing machinery, Invoit Plast offers cutting-edge mixer machines that are:

- Engineered for high-performance output

- Made using premium-grade stainless steel

- Equipped with energy-efficient motors and smart control panels

- Designed for long operational life and minimal maintenance

Invoit Plast’s machines are trusted across industries for their unmatched precision, mixing efficiency, and robust design. Whether you need a standard model or a custom-built solution, Invoit Plast delivers value with every unit.

Final Thoughts

Understanding the working principle of high-speed mixer machines highlights why they are such a critical component in plastic and chemical manufacturing. Their ability to mix materials uniformly, quickly, and with pre-heating advantages sets them apart from traditional mixers.

As industries continue to demand faster and more efficient processing, high-speed mixers will remain essential in ensuring product quality and operational efficiency. If you’re planning to upgrade or invest in a high-speed mixer machine, Invoit Plast Machinery PVT Ltd should be your go-to manufacturer in India for quality, reliability, and performance.

FAQs

A high-speed mixer machine is used to blend plastic raw materials, additives, and colorants quickly and uniformly. It’s widely applied in plastic processing industries, especially for preparing PVC compounds before extrusion or molding. The machine enhances productivity by reducing mixing time and improving material quality.

A high-speed mixer works by rotating impeller blades at high RPM, creating a strong vortex inside the mixing drum. This movement generates centrifugal force and frictional heat, lifting and blending materials rapidly. The result is a consistent, homogeneous mixture in a short time.

High-speed mixers can handle a variety of materials including:

- PVC resin

- HDPE/LDPE/PP granules

- Color masterbatches

- Plastic additives (stabilizers, lubricants, fillers)

- Chemical powders

These mixers are designed to work with both powders and granules.

Key benefits include:

- Fast and efficient mixing

- Uniform dispersion of materials

- Reduced energy usage

- Frictional pre-heating of plastic resins

- Compact design with high output

- Less wear and tear, long lifespan

Yes, the frictional heat generated during high-speed mixing softens plastic resins, helping them absorb additives more efficiently. This pre-conditioning improves processing in the next stages like extrusion, reduces energy consumption, and enhances final product quality.

Look for:

- Mixing capacity that suits your production needs

- Stainless steel drum and blades for durability

- Adjustable speed settings

- Safety features and automation options

- After-sales service and warranty

Always choose machines from reputed manufacturers like Invoit Plast Machinery PVT Ltd, known as the Best High-Speed Mixer Manufacturer in India.

Yes. Manufacturers like Invoit Plast offer customized solutions based on your application requirements, such as capacity, control options, discharge design, and material compatibility.

Most high-speed mixers can complete a mixing cycle in 5 to 10 minutes, depending on the material type, batch size, and desired consistency. This makes them ideal for high-volume production.

Absolutely. Despite high RPM, these machines are designed for short mixing cycles, reducing overall energy consumption per batch. Invoit Plast’s high-speed mixers are built with energy-efficient motors and optimized blade geometry.