Why Invoit Plast Manufactures the Best Slow Speed Granulator Machine in the Market

In the fast-paced plastic processing and recycling industry, the need for precise, energy-efficient, and durable machinery is more important than ever. Among the various machines used in material handling and recycling, the slow speed granulator machine has emerged as a vital solution for handling scrap, sprues, runners, and rejected parts directly beside the injection molding or blow molding machines.

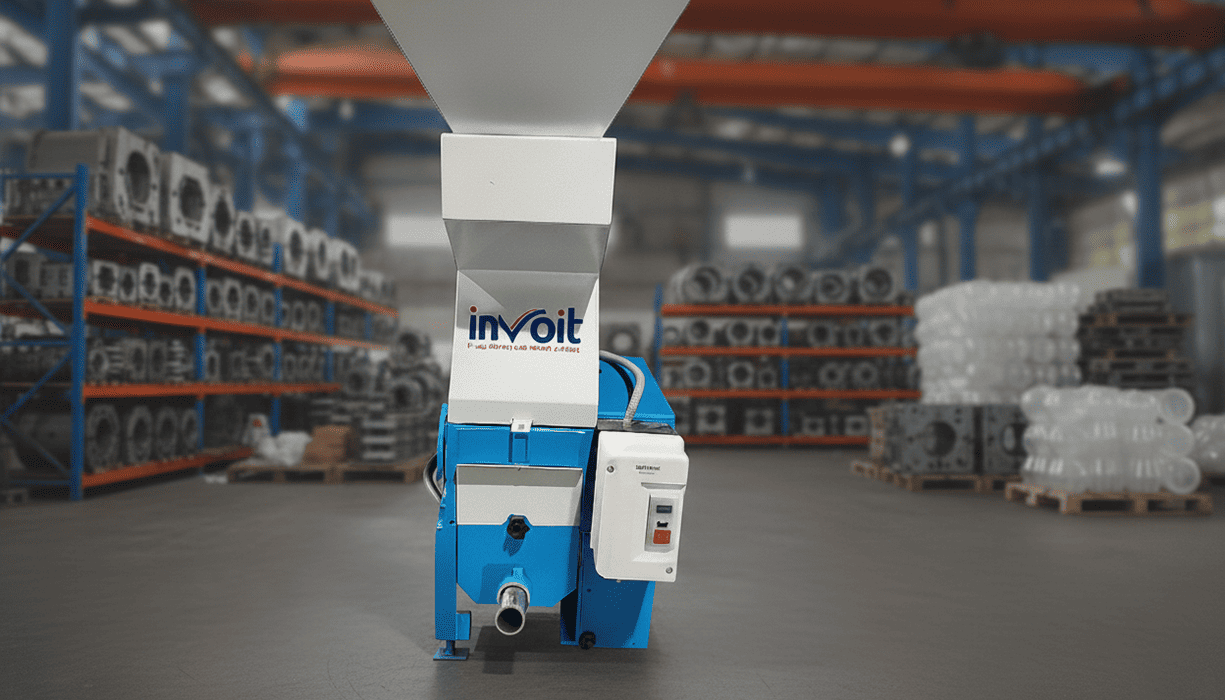

When it comes to finding the perfect slow speed granulator for industrial needs, businesses look for a combination of quality engineering, robust build, operational efficiency, and long-term performance. This is where Invoit Plast Machinery Pvt. Ltd. sets the benchmark. Recognized as the best slow speed granulator machine manufacturer in India, the company offers machines designed to deliver maximum output with minimal maintenance, making them the preferred choice for plastic manufacturers worldwide.

Understanding the Importance of a Slow Speed Granulator

A slow speed granulator is designed to process plastic scrap at a lower rotational speed compared to standard granulators. This slow speed reduces heat generation, prevents material degradation, and ensures uniform particle size, making it ideal for processing materials that require gentle handling.

Unlike high-speed models, slow speed granulators operate quietly, consume less energy, and are more suitable for in-line recycling beside production machines. They are often used for recycling sprues and runners without affecting the physical or chemical properties of the material. This is especially important for industries looking to maintain consistent product quality while reducing waste.

Invoit Plast – Engineering Excellence in Every Machine

One of the main reasons Invoit Plast Machinery Pvt. Ltd. stands out is its commitment to engineering precision. Every slow speed granulator manufactured is the result of extensive research, advanced design, and rigorous quality testing. The company understands that in the competitive plastic industry, a machine is only as good as its ability to deliver consistent results.

The design team at Invoit Plast focuses on cutting-edge technology, high-grade raw materials, and user-friendly operation. From the selection of components to the assembly process, every stage undergoes strict quality control to ensure the machine’s durability and reliability.

Key Advantages of Invoit Plast Slow Speed Granulator Machines

Invoit Plast has earned its place in the industry by offering machines that go beyond the basics. Here’s what makes their slow speed granulators the best choice:

Energy Efficiency

Operating at lower speeds means reduced power consumption, making Invoit Plast’s machines ideal for companies aiming to cut down on operational costs while maintaining productivity.

Minimal Dust and Noise

The slow rotational speed minimizes dust generation, improving workplace safety and cleanliness. These machines also operate with significantly lower noise levels compared to conventional granulators, ensuring a more comfortable working environment.

Superior Cutting Technology

The granulators are equipped with precision-engineered cutting blades that ensure uniform granule size, enhancing the reusability of recycled material without compromising quality.

Durability and Long Service Life

Built from high-strength steel and wear-resistant components, these machines are capable of delivering consistent performance for years, even in heavy-duty production environments.

Ease of Maintenance

The machines are designed for quick and easy cleaning, with easily replaceable blades and simple access to internal components. This reduces downtime and boosts productivity.

Versatility in Application

Whether it’s injection molding scrap, blow molding waste, or extruder rejects, Invoit Plast slow speed granulators handle a wide range of materials with equal efficiency.

Why Businesses Choose Invoit Plast Over Competitors

While there are many granulator machine manufacturers in the market, Invoit Plast Machinery Pvt. Ltd. has built a reputation for delivering consistent value and unmatched after-sales support.

Proven Industry Expertise

With years of manufacturing experience, the company understands the operational challenges faced by plastic product manufacturers and designs machines accordingly.

Customized Solutions

Invoit Plast offers customization options to meet unique operational needs. From machine size to blade configuration, every unit can be tailored for specific production requirements.

Competitive Pricing with Premium Quality

Despite offering premium quality machines, Invoit Plast maintains competitive pricing, making them an excellent investment for small, medium, and large-scale enterprises.

Strong After-Sales Support

The company provides prompt technical assistance, genuine spare parts, and maintenance support to ensure uninterrupted operations.

Contribution to Sustainable Manufacturing

In today’s environmentally conscious manufacturing sector, companies are under pressure to reduce waste and improve recycling efficiency. Invoit Plast slow speed granulator machines play a crucial role in achieving these goals. By enabling in-line recycling, they reduce the need for transporting scrap, lower waste disposal costs, and minimize the environmental impact of plastic production.

These machines help manufacturers meet sustainability targets while ensuring consistent product quality, making them an essential investment for forward-thinking companies.

Global Quality Standards with Indian Manufacturing Strength

Invoit Plast Machinery Pvt. Ltd. combines world-class engineering with cost-effective Indian manufacturing advantages. The company adheres to strict international quality standards while leveraging advanced manufacturing facilities in Ahmedabad, India. This balance allows them to offer global-level performance at competitive prices, attracting both domestic and international clients.

The company’s slow speed granulators are not just popular in India—they have gained recognition in global markets for their efficiency, precision, and reliability.

Future-Ready Design for Evolving Industry Needs

The plastic manufacturing sector is constantly evolving, with newer materials, production techniques, and sustainability regulations emerging. Invoit Plast stays ahead of these trends by innovating and upgrading its slow speed granulator designs.

By integrating features such as energy-efficient motors, enhanced blade designs, and easy-to-use digital controls, the company ensures that its machines remain relevant and competitive in the long run.

Industries Served by Invoit Plast Slow Speed Granulators

The versatility of Invoit Plast slow speed granulator machines makes them suitable for a wide range of industries, including:

- Plastic injection molding

- Blow molding

- Extrusion processes

- Packaging material production

- Automotive plastic component manufacturing

This adaptability is one of the reasons manufacturers from multiple sectors trust Invoit Plast for their granulation needs.

Final Thoughts – The Benchmark for Quality and Reliability

Choosing the right slow speed granulator machine manufacturer is a decision that impacts production efficiency, material quality, and operational costs. With its unmatched combination of engineering excellence, durability, energy efficiency, and customer support, Invoit Plast Machinery Pvt. Ltd. has firmly established itself as the best slow speed granulator machine manufacturer in India.

By consistently delivering high-performance machines that meet global quality standards, Invoit Plast continues to help businesses improve productivity, reduce waste, and achieve sustainability goals. For companies looking for a reliable partner in the plastic recycling and processing industry, Invoit Plast is the name to trust.

FAQs

A slow speed granulator machine is used to recycle and process plastic waste such as sprues, runners, and rejected parts directly beside injection molding or blow molding machines. It operates at a lower rotational speed, reducing heat generation and preventing material degradation while ensuring consistent granule size.

A slow speed granulator is ideal for in-line recycling because it operates with less noise, consumes less energy, and minimizes dust generation compared to high-speed models. It also helps preserve the material’s original properties, making it suitable for high-quality recycling.

Invoit Plast Machinery Pvt. Ltd. is known for producing slow speed granulators that combine precision engineering, energy efficiency, durability, and easy maintenance. They follow strict quality standards, offer customization options, and provide excellent after-sales support, making them the top choice in India.

Invoit Plast slow speed granulators are designed to operate at lower rotational speeds, which reduces power consumption without compromising on cutting efficiency. The machines use high-quality motors and optimized blade designs to ensure maximum performance with minimal energy usage.

Yes, Invoit Plast slow speed granulators are versatile and can handle various types of plastic waste including injection molding scrap, blow molding waste, extrusion rejects, and packaging material offcuts.

Yes, Invoit Plast provides customization options for machine size, blade configuration, and other features to meet specific production requirements of different industries.

Absolutely. By enabling in-line recycling, slow speed granulators reduce material wastage, cut down on transportation costs for scrap, and support eco-friendly production processes — helping businesses meet their sustainability goals.