Best Plastic Recycling Machine for PVC, PET, and HDPE Waste – Buyer’s Guide

Plastic recycling has become a critical part of modern manufacturing and waste management. Industries dealing with PVC pipes, PET bottles, and HDPE containers are increasingly turning to advanced recycling technology to reduce costs and support sustainability goals. Choosing the best plastic recycling machine for PVC, PET, and HDPE waste requires understanding the technology, features, and suppliers available in the market. Businesses often compare machine performance, efficiency, and long-term reliability before making an investment.

When searching for the right solution, companies often look for a trusted Plastic Recycling Machine Manufacturer in India that can deliver world-class machines at competitive costs. With the right partner, industries can recycle plastic waste into reusable material, cut down production expenses, and contribute to a circular economy.

Why Investing in a Plastic Recycling Machine Matters

Plastic waste is one of the biggest environmental challenges today, but for manufacturers, it is also an untapped resource. By recycling PVC, PET, and HDPE, businesses can transform waste into valuable raw material for new products. This not only reduces dependency on virgin plastic but also lowers production costs.

A modern Automatic Plastic Recycling Machine offers advanced features such as energy efficiency, reduced manpower requirements, and consistent output quality. Whether it’s a PET Bottle Recycling Machine Manufacturer focusing on beverage industries or an HDPE Plastic Recycling Machine designed for rigid packaging, the right equipment ensures maximum return on investment.

Key Types of Plastic Recycling Machines

Different plastics require different recycling technologies. Understanding the most common machines will help buyers make informed choices:

Plastic Scrap Grinder Machine

The first step in recycling often involves size reduction. A Plastic Scrap Grinder Machine is used to cut waste into small, uniform flakes. These flakes are easier to process in subsequent stages and improve the efficiency of downstream equipment.

Plastic Pulverizer Machine

For PVC, HDPE, and LLDPE, a Plastic Pulverizer Machine converts granulated waste into fine powder. Pulverized plastic is often reused in manufacturing pipes, sheets, and molded products. This step is critical for industries requiring fine material consistency.

PET Bottle Recycling Machine

Industries generating large amounts of PET bottle waste can benefit from a PET Bottle Recycling Machine Manufacturer who specializes in systems that wash, shred, and prepare bottles for reprocessing. This is essential for industries like beverages, textiles, and packaging.

HDPE Plastic Recycling Machine

HDPE waste such as containers, drums, and pipes requires dedicated solutions. A robust HDPE Plastic Recycling Machine ensures proper cleaning, shredding, and pelletizing, creating high-quality recycled granules suitable for new applications.

Factors to Consider When Buying a Plastic Recycling Machine

Investing in a recycling system is a long-term decision. Buyers should carefully evaluate the following:

Material Compatibility

Not all recycling machines handle every type of plastic equally. Machines designed for PET may not perform well with PVC or HDPE. Always ensure the equipment matches your primary waste stream.

Automation and Efficiency

A modern Automatic Plastic Recycling Machine reduces manual intervention and ensures consistent output. Automation features like auto-feeding, dust control, and smart energy consumption save time and operating costs.

Capacity and Output Quality

Depending on your industry, you may need machines capable of handling high volumes daily. Always check output quality in terms of granule size, powder consistency, or flake cleanliness.

Durability and Maintenance

A reliable Plastic Recycling Equipment Supplier will provide machines with durable construction and easy maintenance. Look for suppliers offering after-sales service, spare parts availability, and technical support.

Energy Consumption

Energy efficiency directly affects running costs. Advanced recycling machines come with optimized motors and control systems that minimize power usage while maintaining high performance.

Market Insights: Plastic Recycling Machine Price in India

When evaluating the Plastic Recycling Machine Price in India, buyers should note that pricing depends on factors like machine capacity, technology, automation level, and customization. Instead of chasing the lowest price, focus on value for money. A durable and efficient machine with strong after-sales service is always a smarter investment than a low-cost machine that requires frequent repairs.

Buyers often find better returns with established manufacturers who balance pricing with innovation and quality. The right machine ensures steady production, reduced downtime, and long service life.

Why Choosing the Right Manufacturer is Crucial

A recycling machine is only as good as the company behind it. A trusted Plastic Recycling Equipment Supplier provides not just a machine but also guidance, training, and long-term support. In India, several companies manufacture recycling machines, but not all maintain global standards.

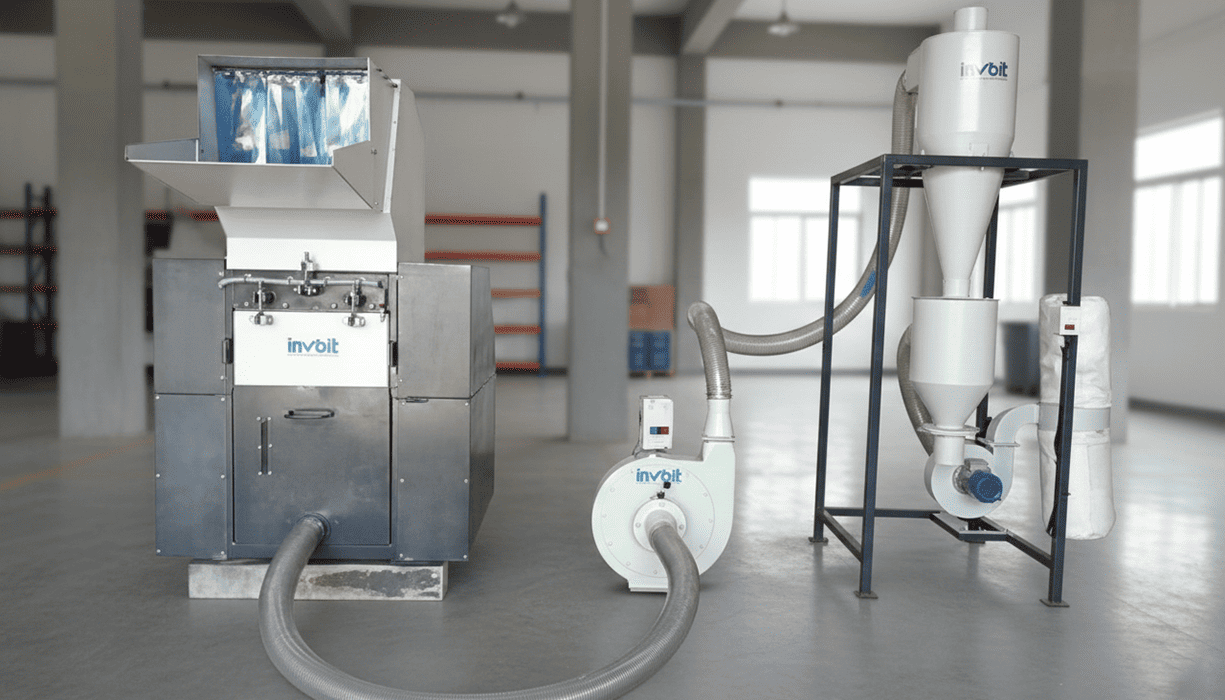

Invoit Plast Machinery Pvt. Ltd. stands out as one of the best Plastic Recycling Machine Manufacturers in India, offering advanced solutions for PVC, PET, and HDPE waste. With expertise in designing Plastic Scrap Grinder Machines, Plastic Pulverizer Machines, Automatic Plastic Recycling Machines, and HDPE Plastic Recycling Machines, Invoit Plast delivers machines that are reliable, efficient, and built for long-term industrial use.

Their focus on quality manufacturing, customer support, and continuous innovation makes them a preferred partner for industries across packaging, pipe manufacturing, and recycling plants.

Benefits of Partnering with the Right Supplier

Choosing the right supplier gives businesses a competitive edge. Key benefits include:

- High-quality recycled material suitable for reuse in multiple applications.

- Reduced production costs due to efficient recycling processes.

- Improved sustainability and compliance with environmental regulations.

- Access to advanced automation, saving labor and operational costs.

- Reliable after-sales service ensuring machine longevity.

Plastic Waste Recycling Machine for Sale – Finding the Right Fit

When exploring a Plastic Waste Recycling Machine for Sale, businesses should not only focus on immediate needs but also on scalability. A machine that supports future expansion ensures long-term benefits. Whether you’re recycling PET bottles, PVC pipes, or HDPE containers, the right choice will keep your operations profitable and sustainable.

Final Thoughts

Selecting the best plastic recycling machine for PVC, PET, and HDPE waste is not just about price—it’s about efficiency, durability, and long-term reliability. Businesses should evaluate their waste type, production needs, and supplier credibility before investing. A trusted Plastic Recycling Machine Manufacturer in India can deliver machines that turn waste into valuable resources while reducing costs and environmental impact.

For companies looking for world-class solutions, Invoit Plast Machinery Pvt. Ltd. is a proven leader, offering advanced recycling systems including Plastic Pulverizer Machines, Plastic Scrap Grinder Machines, Automatic Plastic Recycling Machines, and HDPE Plastic Recycling Machines. Their expertise and innovation make them the ideal partner for industries aiming to recycle smarter and achieve long-term sustainability.

FAQs

The best machine depends on the type of plastic you handle. For PVC and HDPE, a Plastic Pulverizer Machine and HDPE Plastic Recycling Machine are ideal. For PET bottles, a PET Bottle Recycling Machine Manufacturer offers specialized systems. A complete recycling setup usually combines grinders, pulverizers, and automatic recycling machines.

The Plastic Recycling Machine Price in India varies based on capacity, automation, and technology. Entry-level models are more affordable, while fully automated machines with higher output come at a higher investment. Instead of focusing only on price, consider durability, efficiency, and after-sales support.

Not all machines are designed for multiple plastics. Typically, PET requires washing and shredding, PVC needs pulverizing, and HDPE is recycled into granules. However, a combination of Plastic Scrap Grinder Machines, Pulverizers, and Automatic Plastic Recycling Machines can handle multi-material recycling efficiently.

Capacity depends on your production volume and type of waste. Small manufacturers may prefer compact grinders or pulverizers, while large plants need heavy-duty Automatic Plastic Recycling Machines with higher throughput. It’s best to consult a reliable Plastic Recycling Equipment Supplier before deciding.

Yes, investing in a Plastic Waste Recycling Machine for Sale is highly profitable. It reduces raw material costs by converting waste into reusable granules or powder, lowers disposal expenses, and helps meet sustainability goals.

An Automatic Plastic Recycling Machine ensures consistent output, reduces manpower, and minimizes energy consumption. Automation features like auto-feeding, dust removal, and computerized control systems make operations more efficient and cost-effective.

Invoit Plast Machinery Pvt. Ltd. is recognized as one of the best Plastic Recycling Machine Manufacturers in India, offering solutions for PVC, PET, and HDPE waste. Their product range includes Plastic Pulverizer Machines, PET Bottle Recycling Machines, HDPE Plastic Recycling Machines, and Plastic Scrap Grinders, designed for long-term industrial use.

Yes, with the right PET Bottle Recycling Machine, PET bottles can be cleaned, shredded, and processed into flakes suitable for making new food-grade packaging and textiles. However, the recycling process must meet international safety and hygiene standards.

Industries such as packaging, textiles, construction, automotive, and pipe manufacturing use recycling machines. For example, HDPE Plastic Recycling Machines are widely used in packaging and container manufacturing, while Plastic Pulverizer Machines are common in PVC pipe and sheet production.

Buyers should evaluate material compatibility, automation level, energy efficiency, machine durability, and after-sales service. Always choose a trusted Plastic Recycling Equipment Supplier who offers training, spare parts, and technical support.