How to Increase Production Efficiency with Plastic Scrap Grinder Machines

In today’s competitive plastics industry, every manufacturer is under pressure to improve productivity, reduce material costs, and ensure sustainable operations. One of the most effective ways to achieve these goals is by using a Plastic Scrap Grinder Machine in India. These machines play a critical role in recycling and reusing plastic waste, converting it into reusable granules for production.

If you’re looking for practical ways to enhance production efficiency, integrating a high-quality Plastic Scrap Grinder Machine into your process is a smart move. Let’s dive deeper into how these machines help businesses optimize operations and why choosing the right Plastic Grinder Machine Manufacturer in India matters.

Why Plastic Scrap Grinder Machines are Essential for Modern Manufacturing

Plastic waste is an inevitable by-product in every manufacturing unit, especially in industries producing packaging materials, household goods, automotive parts, or plastic containers. If not managed efficiently, this scrap can lead to increased storage costs and higher raw material expenses.

A Plastic Scrap Grinder Machine solves this problem by grinding the waste material into uniform granules, which can be directly used in the production cycle. This ensures:

- Cost Reduction: Reduces the need for virgin plastic material.

- Resource Optimization: Reuses internal scrap, improving sustainability.

- Operational Efficiency: Minimizes downtime associated with waste handling.

Companies investing in these machines not only improve cost-effectiveness but also meet sustainability goals by reducing plastic waste.

How Plastic Scrap Grinder Machines Improve Production Efficiency

A Plastic Grinding Machine is more than just a recycling tool; it’s an efficiency booster for your entire production line. Here’s how it impacts productivity:

Continuous Recycling of Scrap

In any molding or extrusion process, leftover plastic material is unavoidable. A Plastic Scrap Grinder Machine in India allows you to grind and reuse this material immediately, creating a continuous production loop without delays or waste pile-up.

Lower Material Procurement Costs

By converting in-house waste into reusable granules, you minimize dependency on purchasing new raw material. This directly reduces costs and gives you better control over material inventory.

Streamlined Workflow

Handling and disposing of plastic waste is time-consuming. Integrating a Plastic Scrap Grinder Machine into your system simplifies waste management, reducing manual labor and operational bottlenecks.

Consistent Quality in Reprocessed Material

Modern grinders ensure uniform particle size and consistency, which is crucial for maintaining quality standards in finished products.

Choosing the Right Plastic Scrap Grinder Machine Manufacturer

Selecting the right machine is as important as the decision to use one. Partnering with a trusted Plastic Grinder Machine Manufacturer in India ensures you get durable equipment with high performance and low maintenance needs. Key factors to consider include:

- Build Quality and Materials: A strong body and high-grade blades guarantee long-lasting performance.

- Motor Power and Output Capacity: Choose a grinder that matches your production requirements.

- Ease of Maintenance: Machines with simple designs and easily replaceable parts reduce downtime.

- Energy Efficiency: Opt for grinders that consume less power while delivering maximum output.

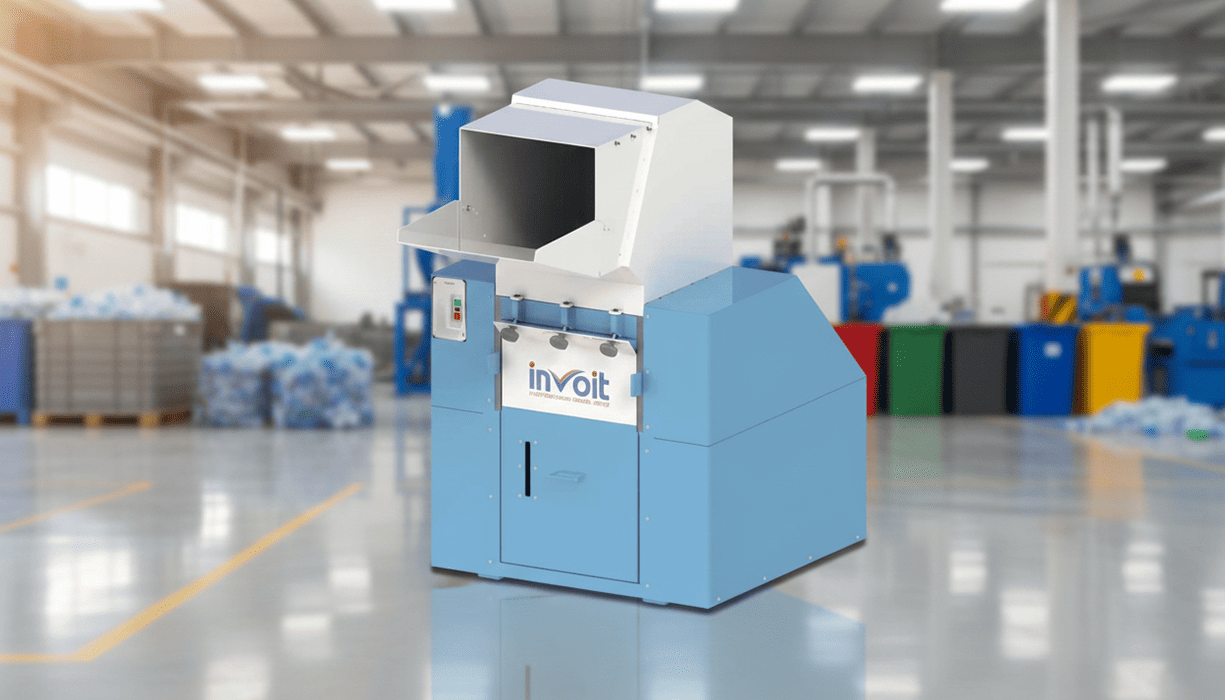

When it comes to reliability and performance, Invoitplast Machinery PVT LTD is the Best Plastic Scrap Grinder Manufacturer in Ahmedabad, India, offering robust machines designed for continuous, heavy-duty operations. Their solutions cater to diverse industries, ensuring both efficiency and cost savings.

Advantages of Using a Plastic Scrap Grinder Machine in India

The benefits of investing in a high-quality Plastic Scrap Grinder Machine extend beyond recycling. Some key advantages include:

- Waste Reduction: Eliminates the problem of scrap accumulation.

- Eco-Friendly Operations: Promotes a circular economy by reusing plastic waste.

- Improved ROI: Lowers raw material costs and enhances profitability.

- Versatility: Suitable for different types of plastic materials like HDPE, LDPE, PET, PVC, and PP.

- Space Optimization: Reduces storage requirements for plastic waste.

With these advantages, it’s clear that a grinder is not just an accessory but a necessity for modern plastic manufacturing units.

Why Invest in a High-Performance Plastic Grinding Machine?

Not all grinders are created equal. A poorly designed machine can lead to inconsistent granules, frequent breakdowns, and higher energy bills. On the other hand, a high-performance grinder ensures:

- Uniform Output: Critical for maintaining product quality in reprocessing.

- Long Life Blades: Superior blade quality reduces replacement frequency.

- Noise and Vibration Control: Improves operator comfort and safety.

- Low Maintenance Costs: Advanced designs reduce wear and tear.

By choosing the right machine from a reputable Plastic Scrap Grinder Machine Manufacturer, you ensure reliability, efficiency, and long-term value for your investment.

Future of Plastic Scrap Grinding in India

As industries move towards zero-waste policies and stricter environmental regulations, the role of Plastic Scrap Grinder Machines in India will become even more critical. Manufacturers adopting these machines will not only stay compliant but also gain a competitive edge by reducing costs and promoting sustainable practices.

With rapid technological advancements, modern grinders now offer energy-saving features, automation, and improved safety systems, making them an integral part of future-ready plastic processing plants.

Final Thoughts

Investing in a Plastic Scrap Grinder Machine is no longer optional—it’s essential for any manufacturer aiming for efficiency, cost savings, and sustainability. These machines help reduce waste, optimize resources, and streamline production, giving your business a significant competitive advantage.

If you’re searching for a trusted partner, Invoitplast Machinery PVT LTD is the Best Plastic Scrap Grinder Manufacturer in Ahmedabad, India, delivering advanced, durable, and high-performance machines tailored to your production needs.

With the right grinder, your plastic manufacturing process can become more efficient, eco-friendly, and profitable. Make the smart move today and take your production efficiency to the next level.

FAQs

A Plastic Scrap Grinder Machine is a recycling device used to grind plastic waste into small, reusable granules for manufacturing new plastic products.

It reduces waste, lowers raw material costs, and enables continuous recycling, which streamlines workflow and improves overall productivity in plastic manufacturing.

These machines are widely used in packaging, automotive, household goods, pipe manufacturing, and plastic product recycling industries.

Look for build quality, motor power, output capacity, blade durability, ease of maintenance, and energy efficiency when choosing a grinder.

Invoitplast Machinery PVT LTD is a leading Plastic Scrap Grinder Machine Manufacturer in Ahmedabad, India, offering high-performance and durable solutions.

Yes. High-quality grinders can process HDPE, LDPE, PET, PVC, and PP plastics, making them versatile for various manufacturing applications.

Absolutely. It lowers raw material costs, minimizes waste, and improves ROI by recycling scrap into usable granules for continuous production.

They reduce plastic waste, promote reusability, and help companies adopt eco-friendly manufacturing practices by creating a circular economy.

No. Modern machines are designed for low maintenance and long life, especially when purchased from a trusted Plastic Grinder Machine Manufacturer in India.

With growing environmental regulations and zero-waste policies, these machines will become essential for cost efficiency and sustainable production.