Stop Losing Money on Scrap: Your ROI Guide to Plastic Granulator Machines

In today’s fast-paced manufacturing and recycling industries, scrap plastic is often seen as a costly problem. But what if we told you that this waste could actually become one of your biggest profit-making opportunities? With the right Plastic Granulator Machine, you can transform plastic waste into high-quality granules that can be reused or sold—helping you save costs, improve efficiency, and maximize your ROI.

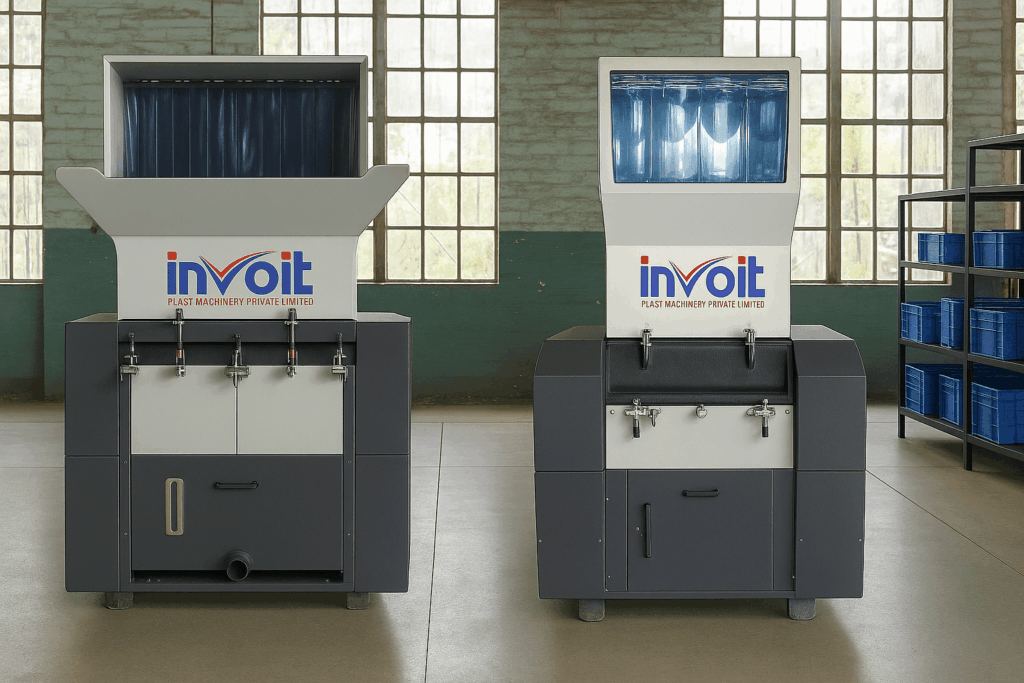

At Invoit Plast Machinery Pvt. Ltd., we specialize in designing and manufacturing world-class Plastic Granulator Machines tailored to meet the needs of industries across India and beyond. This guide will help you understand why investing in a Plastic Granulator is the smartest move to stop losing money on scrap and start seeing real returns.

Why Scrap is Costing You More Than You Think

Plastic scrap isn’t just about waste lying around your facility—it has hidden costs that directly eat into your profits:

- Storage Costs – Piles of plastic waste take up valuable floor space that could be used for production.

- Disposal Costs – Sending scrap to landfills or disposal facilities comes with recurring expenses.

- Missed Revenue – Every kilo of wasted plastic is a missed opportunity to recycle and resell.

- Environmental Impact – Inefficient handling of plastic waste hurts your sustainability credentials.

By using an Industrial Plastic Granulator Machine, you can cut these costs, generate reusable material, and even create an additional revenue stream.

What is a Plastic Granulator Machine?

A Plastic Granulator Machine is a high-performance piece of recycling equipment designed to break down plastic waste into uniform granules. Unlike a simple crusher, which only reduces size, a granulator delivers consistent granule quality suitable for direct reuse in production or for sale to plastic processors.

These machines are essential in industries such as packaging, injection molding, blow molding, extrusion, and recycling plants. Whether you need a Plastic Scrap Granulator Machine for small-scale operations or a heavy-duty Plastic Waste Granulator for industrial use, the right equipment ensures cost savings and better ROI.

How Plastic Granulator Machines Improve ROI

Investing in a Plastic Recycling Granulator is not just about reducing waste—it’s about turning waste into profit. Here’s how:

Cutting Raw Material Costs

Instead of buying fresh plastic resin for every production batch, manufacturers can reuse granules made from scrap. A Plastic Granule Making Machine helps you recycle your own waste, reducing dependency on external suppliers.

Creating New Revenue Streams

High-quality granules produced by an Industrial Plastic Granulator Machine can be sold in the market at competitive rates. Many recycling businesses generate consistent revenue by supplying granules to other manufacturers.

Lowering Waste Management Costs

Disposal fees, transportation costs, and landfill taxes can add up. By installing a Plastic Crusher and Granulator, you reduce the need for disposal, saving money over time.

Improving Production Efficiency

Granulated scrap is easier to handle, transport, and feed back into the production line. This improves material flow and reduces downtime.

Boosting Sustainability and Brand Image

Today’s customers and partners value eco-friendly businesses. Using a Plastic Granulator Machine for Recycling helps you meet sustainability goals while boosting your brand reputation.

Choosing the Right Plastic Granulator Machine

When it comes to selecting a Plastic Granulator, several factors determine whether your investment will deliver strong ROI:

- Material Type – Different plastics like PET, PVC, HDPE, and PP require specific machine designs.

- Granule Size Requirement – Depending on whether granules are for reuse or resale, you may need fine or coarse granulation.

- Capacity & Throughput – For large-scale operations, an Industrial Plastic Granulator Machine with higher capacity ensures efficiency.

- Energy Efficiency – Look for machines that consume less power while delivering consistent performance.

- Maintenance & Durability – A robust machine reduces downtime and keeps your production running smoothly.

At Invoit Plast Machinery Pvt. Ltd., we help businesses choose the perfect machine based on their scrap volume, plastic type, and operational needs.

Plastic Granulator Machine Price: A Cost vs. Benefit View

One of the most common questions buyers have is about the Plastic Granulator Machine Price. While the upfront cost may vary depending on size, features, and capacity, the real value lies in long-term savings and profit generation.

Think of it this way:

- Without a granulator → Continuous expenses on waste disposal + high cost of virgin plastic raw materials.

- With a granulator → Reuse of scrap + extra revenue from granule sales + lower waste handling expenses.

Over time, the investment pays for itself, often within months, making a Plastic Recycling Granulator one of the most cost-effective purchases for manufacturers.

Applications of Plastic Granulator Machines

Granulators are not limited to recycling plants. They are widely used in:

- Injection Molding Units - To recycle sprues and rejected products.

- Blow Molding Industries - To reuse bottles and containers.

- Packaging Industry - For recycling films, sheets, and packaging materials.

- Extrusion Plants - To handle plastic pipes, profiles, and sheets.

- Municipal Waste Facilities - To process post-consumer plastics.

This wide range of applications makes the Plastic Scrap Granulator Machine a universal solution for businesses looking to maximize ROI.

Why Choose Invoit Plast Machinery Pvt. Ltd.?

When investing in recycling machinery, the choice of manufacturer is critical. Here’s why Invoit Plast Machinery Pvt. Ltd. stands out as the best Plastic Granulator Machine manufacturer and supplier in India:

- Expertise & Innovation – Years of experience in designing high-quality plastic recycling equipment.

- Wide Product Range – From Plastic Waste Granulators to Plastic Crusher and Granulators, we provide solutions for every need.

- Quality Manufacturing – Robust, durable machines designed for heavy-duty use.

- Affordable Pricing – Competitive Plastic Granulator Machine Prices without compromising on quality.

- After-Sales Support – Dedicated service and spare parts availability for uninterrupted performance.

- Trusted by Industries – Our machines are already powering manufacturing and recycling units across India.

By choosing Invoit Plast, you’re not just buying a machine—you’re investing in long-term profitability, efficiency, and sustainability.

Key Takeaways

- Scrap plastic is not waste—it’s an untapped source of profit.

- A Plastic Granulator Machine for Recycling reduces costs, generates revenue, and supports sustainability.

- ROI comes from lower raw material expenses, higher resale value, and reduced disposal costs.

- The right choice of machine ensures better performance and quicker returns.

- Invoit Plast Machinery Pvt. Ltd. is your trusted partner for Plastic Granulator Machines in India.

Final Thoughts

If you’re tired of watching money slip away with every scrap of plastic, it’s time to rethink your waste strategy. An Industrial Plastic Granulator Machine doesn’t just recycle—it creates value. By investing in the right granulator, you can turn plastic scrap into profitable granules, reduce costs, and boost your bottom line.

At Invoit Plast Machinery Pvt. Ltd., we are committed to helping businesses stop losing money on scrap and start achieving higher ROI with our advanced range of Plastic Granulator Machines.

FAQs

A Plastic Granulator Machine is a recycling machine that converts plastic scrap into uniform granules for reuse or resale, improving efficiency and reducing waste.

By recycling scrap into reusable granules, you save on raw material costs, reduce disposal expenses, and can sell granules, creating new revenue streams.

Plastic Granulators handle various types of plastics, including HDPE, PET, PVC, PP, and more. The machine can be customized for specific scrap types.

Consider factors like material type, granule size, capacity, energy efficiency, and durability. Invoit Plast Machinery Pvt. Ltd. helps select machines that maximize ROI.

Plastic Granulator Machine Price varies by capacity, features, and model. Investing in a quality granulator pays off by lowering waste disposal costs and generating additional revenue.

We are a leading Plastic Granulator Machine Manufacturer & Supplier in India, offering durable, high-performance machines with expert support and competitive pricing.