Boost Your Pipe Production Efficiency with Invoit Plast Plastic Pulverizers – Trusted by Indian Manufacturers

The Indian plastic pipe manufacturing sector stands at a critical juncture. Rapid infrastructure development, coupled with increasing environmental scrutiny, has heightened the pressure on producers to achieve operational excellence. In this high-stakes environment, efficiency is not just a goal—it is the bedrock of profitability.

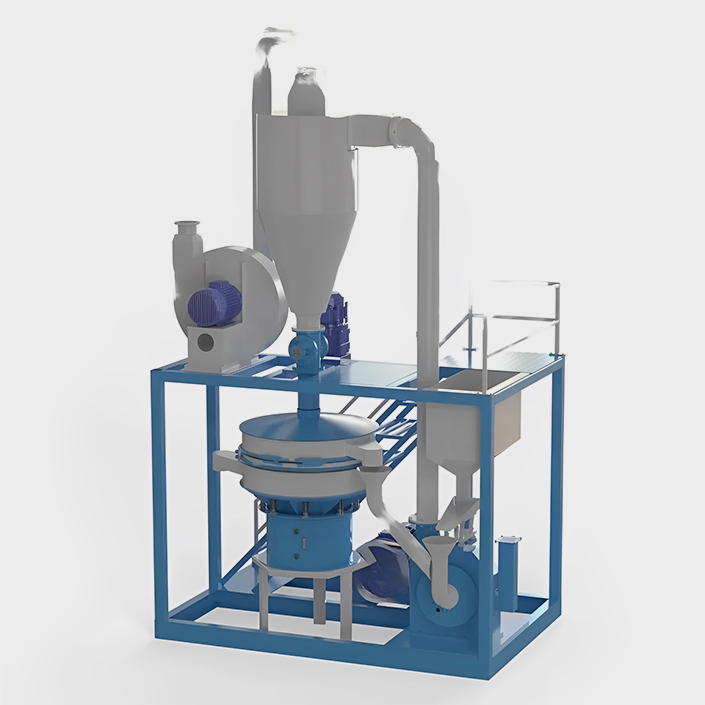

Every Indian pipe manufacturer understands that material cost management, consistent product quality, and the reliable reintroduction of waste into the production cycle are paramount. This entire equation hinges on one powerful, yet often undervalued, machine: the industrial plastic pulverizer for sale. It’s the difference between accumulating costly scrap and running a profitable, closed-loop system.

This detailed guide confirms why Indian manufacturers trust Invoit Plast—the Best Invoit Plast Plastic Pulverizer Machine Manufacturer in India—to deliver the precision, durability, and cost-efficiency required to stay ahead in this fiercely competitive market.

The Efficiency Imperative: Why Pulverization Defines Profit

In pipe extrusion, waste is inevitable. End cuts, sizing issues, and defective runs produce significant amounts of hard plastic scrap. While a basic pre-crusher or plastic scrap grinder can reduce the size of the material, it is the pulverizer’s ability to turn this waste into a high-quality, reusable plastic powder making machine for PVC feed that unlocks true efficiency.

For uPVC and CPVC pipe production, the quality of the regrind powder directly impacts the mechanical properties and surface finish of the final product. Introducing improperly milled or inconsistently sized powder can lead to:

- Surging and Density Issues: Inconsistent powder bulk density compromises feeder accuracy, leading to fluctuations in the extrusion rate.

- Product Defects: Oversized particles can cause blockages or create weak points and blemishes on the pipe’s surface, resulting in costly rejections.

- Increased Energy Use: Poorly designed machines spend excessive energy generating friction, rather than efficiently reducing particle size.

This is precisely why pipe manufacturers must move beyond treating their pulverizer as just a plastic grinding machine and recognize it as a high-precision component of their entire material handling ecosystem. A high-performance pulverizer ensures that the regrind material is virtually indistinguishable from virgin powder, allowing high ratios of recycling without compromising the quality trusted by structural engineers and contractors across India.

Tailoring Technology: Specialized Pulverization for uPVC and HDPE

Different plastic polymers demand distinct pulverization approaches. A machine designed for general grinding will often fail when faced with the thermal and structural properties of specialized materials like rigid PVC (uPVC) and High-Density Polyethylene (HDPE).

1. The uPVC Pipe Pulverizer Machine: Mastering Thermal Sensitivity

Unplasticized PVC (uPVC) is rigid and highly sensitive to heat. The friction generated during high-speed grinding can cause the PVC to melt, fuse, and degrade—a phenomenon known as thermal runaway. This degradation dramatically reduces the quality and longevity of the final pipe.

A top-tier uPVC pipe pulverizer machine must be specifically engineered to mitigate this heat. Key features must include:

- Advanced Water-Cooled Systems: Efficiently jacketing the grinding chamber, discs, and bearings to rapidly dissipate heat and maintain stable process temperatures.

- Optimal Disc Geometry: Specialized grinding disc profiles that reduce friction while maximizing impact to achieve the required mesh size (typically 30 to 60 mesh for extrusion) rapidly.

- Automatic Temperature Monitoring: Integrated sensors and controls that shut down or slow the feed rate if the temperature threshold is breached, protecting the polymer’s integrity.

When you invest in a Plastic PVC Pulverizer Machine Manufacturer like Invoit Plast, you are investing in technology engineered to handle the specific thermal challenges of PVC, guaranteeing a high-quality, reusable powder for your pipe line in India.

2. HDPE Pulverizer Machine for Rotomolding: Perfecting Flow Properties

While uPVC pipes use extrusion, many associated products, such as water storage tanks and large fittings, utilize Rotational Moulding (Rotomolding). Rotomolding relies entirely on plastic powder (usually LLDPE or HDPE) with specific flow characteristics and bulk density. Powder that is too coarse, irregular, or contains fines will lead to pinholes, incomplete mold coverage, and wasted production time.

The requirements for an HDPE pulverizer machine for rotomolding are focused less on preventing thermal degradation (as HDPE has a higher melting point than PVC) and more on achieving:

- Consistent Spherical Particle Shape: Rounder particles flow and pack better, which is essential for uniform mold coverage.

- Narrow Particle Size Distribution (PSD): Minimal variation in particle size ensures uniform melting and consistent wall thickness in the final product.

Invoit Plast’s versatility ensures that whether you are processing uPVC scrap for extrusion or HDPE granules for rotomolding, you have a purpose-built machine capable of delivering the exact powder specification needed for superior end-product quality.

Invoit Plast: The Best Plastic Pulverizer Manufacturer in India

Selecting the right equipment partner is a strategic decision that affects your facility’s uptime, output, and long-term cost of ownership. In the competitive Indian market, Invoit Plast has risen to prominence as the Best plastic pulverizer manufacturer by focusing relentlessly on three core pillars: Durability, Throughput, and Support.

Unmatched Durability and Build Quality

Indian manufacturing environments are tough, often involving long shifts and ambient heat. Inferior machines suffer from rapid wear and tear. Invoit Plast’s industrial plastic pulverizer for sale features robust construction using high-grade materials:

- Superior Grinding Discs: Made from hardened alloy steel, our discs ensure extended operational life and maintain a sharp profile for longer, reducing the frequency and cost of replacements.

- Heavy-Duty Bearings: Oversized and efficiently cooled bearing systems minimize vibration and wear, leading to greater stability and reduced downtime.

- Sturdy Structure: Our pulverizers are built to withstand continuous, heavy-duty operation, guaranteeing a reliable asset that will last for years.

This focus on structural integrity is why countless Indian manufacturers rely on us for their most demanding recycling needs.

Maximizing Throughput with Minimal Energy

The true measure of a pulverizer is its ability to produce the highest volume of quality powder per kilowatt-hour consumed. Our engineers constantly refine the core mechanics to deliver high efficiency:

- Optimized Airflow and Blower System: An effective airflow system rapidly carries the finished powder away from the grinding zone. This dual function not only prevents overheating but also increases the effective throughput capacity of the machine.

- Digital Control and Automation: Features like automatic feed rate control based on the motor load and powder temperature (optional sensors) prevent overloading, optimize power consumption, and ensure consistent powder output even during long production runs.

When looking for an industrial plastic pulverizer for sale, the Invoit Plast machine represents an investment in superior throughput and lower per-kilogram operational costs.

Reliable Support: A Local Partner in India

Being a leading Plastic PVC Pulverizer Machine Manufacturer in India means providing local, timely support. Our commitment to being the Best Invoit Plast Plastic Pulverizer Machine Manufacturer in India extends beyond the sale to comprehensive after-sales service, readily available spare parts, and expert technical guidance across the country. This localized presence ensures minimal downtime and keeps your production line running smoothly.

The Value Equation: Understanding the PVC Pulverizer Machine Price in India

In any major capital expenditure decision, the PVC pulverizer machine price in India is a key consideration. However, focusing solely on the cheapest initial purchase price is a common pitfall that often results in higher total cost of ownership (TCO).

Factors Driving the Investment and TCO

Cost Component | Impact of Low-Quality Machine | Invoit Plast Advantage |

Energy Consumption | High HP motor running inefficiently leads to massive electricity bills. | Optimized design and efficient motors (e.g., Siemens/ABB) deliver high output at a lower kW/h ratio. |

Downtime & Maintenance | Frequent bearing failures, disc replacements, and unscheduled stops severely cut into production targets. | Superior build quality, alloy steel components, and advanced cooling drastically reduce maintenance and improve uptime. |

Material Quality | Inconsistent powder leads to rejected final products, meaning the recycled material is wasted. | Precision grinding ensures consistent powder quality, allowing higher regrind ratios and saving on virgin material procurement. |

Machine Lifespan | Lower-grade mild steel construction and poor design necessitate replacement sooner. | Robust, heavy-duty design provides a longer, more reliable service life, protecting your investment. |

The Competitive PVC Pulverizer Machine Price in India

While we cannot list every model price here due to customization and market fluctuations, understanding the price range is essential for budgeting. Generally, the PVC pulverizer machine price in India is influenced by capacity (e.g., 100 kg/hr to 500 kg/hr), motor power (e.g., 30 HP to 75 HP), and additional features like water chilling units and fully automated control panels.

For manufacturers seeking transparent, competitive pricing that reflects genuine, long-term value, Invoit Plast offers tailored solutions. We ensure that our quotation provides the most competitive value proposition in the Indian market, blending high-end performance with affordable ownership.

We encourage you to engage with our team to discuss your specific capacity needs (uPVC or HDPE), your desired mesh size, and the level of automation you require. We provide a detailed breakdown to help you clearly evaluate the return on investment (ROI) and see how quickly a high-efficiency PVC Pulverizer Machine India can pay for itself through material savings and enhanced productivity.

The Path to Zero-Waste Production

The final frontier of efficiency in plastic pipe manufacturing is the push toward zero-waste, a concept heavily reliant on high-performance recycling infrastructure. By installing an Invoit Plast plastic powder making machine for PVC or a specialized HDPE pulverizer machine for rotomolding, Indian manufacturers are not just purchasing a piece of equipment; they are securing a sustainable competitive advantage.

Our machines enable you to:

- Maximize Regrind Inclusion: Generate exceptionally high-quality powder that can be reintroduced at higher ratios without affecting product specifications.

- Reduce Landfill Costs: Eliminate the disposal cost associated with PVC or HDPE scrap by converting it into a valuable raw material.

- Enhance Sustainability Profile: Meet increasing regulatory and market demands for eco-friendly practices by establishing a true closed-loop recycling system within your facility.

The choice is clear: continue to absorb the losses from inefficient waste handling, or invest in a solution that turns your scrap into immediate revenue.

Secure Your Future Efficiency with Invoit Plast

The journey to optimal pipe production efficiency starts with selecting the right machine. Invoit Plast is ready to partner with you, offering world-class technology engineered for the demands of the Indian manufacturing environment. Our status as the Best plastic pulverizer manufacturer is earned through the trust and operational success of our clients.

Whether you need detailed specifications on our heavy-duty models, a personalized consultation on throughput requirements, or an accurate and transparent PVC pulverizer machine price in India, our expert team is here to assist you. Invest in the best.

Contact Invoit Plast today to request a quote and discover how our industrial plastic pulverizer for sale can revolutionize your material recycling and production efficiency.

FAQs

A grinder or crusher reduces material to coarse flakes. A pulverizer uses high-speed grinding discs to create fine, consistent powder (typically 30-60 mesh) suitable for direct reintroduction into the extrusion or molding process.

uPVC is highly thermal-sensitive. The friction from high-speed grinding can cause it to melt and thermally degrade (thermal runaway), which drastically reduces the quality and longevity of the final pipe product.

For high-quality pipe extrusion, the ideal powder size is generally between 30 and 60 mesh.

PSD stands for Particle Size Distribution. A narrow PSD (minimal variation in particle size) is crucial for HDPE rotomolding to ensure uniform flow, complete mold coverage, and consistent wall thickness in the finished product.

TCO is reduced through three main factors: maximized energy efficiency (lower kW/h ratio), superior component durability (leading to reduced downtime and maintenance), and high-quality output that saves costs on virgin material procurement.