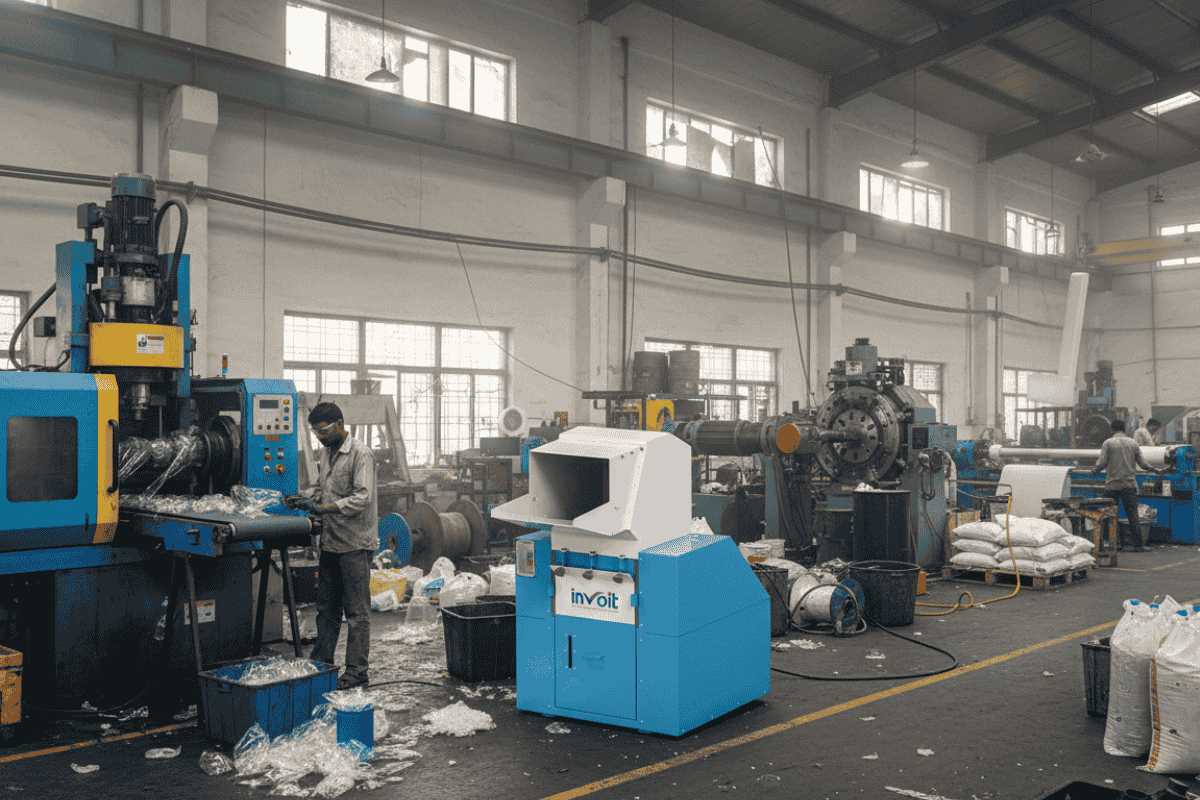

The Best Plastic Scrap Grinder Machine for Injection Molding, Blow Molding & Extrusion Units

The modern plastic manufacturing facility operates on razor-thin margins, where every kilogram of scrap represents a potential loss or a recoverable asset. Efficient size reduction is not just a peripheral activity; it is a critical process that directly impacts your bottom line and material quality. Selecting the right Plastic Scrap Grinder Machine—or Plastic Granulator Machine—is paramount for operational sustainability across Injection Molding, Blow Molding, and Extrusion lines. Whether you are dealing with brittle runners, voluminous bottles, or thick purging lumps, an optimized Plastic Recycling Grinder can transform waste into reusable, valuable regrind, safeguarding your investment in virgin materials. This guide provides a detailed breakdown of the critical factors you must consider to choose the optimal size reduction equipment tailored for your specific processing needs, ensuring efficiency and long-term reliability.

Optimizing Material Reclamation with a Plastic Scrap Granulator

The primary goal of integrating a high-performance Plastic Scrap Granulator is twofold: maximizing material utilization and minimizing operational costs. In-house recycling, often referred to as “regrind,” requires the scrap plastic to be reduced to a uniform, fine particle size that can be easily mixed back into virgin material without disrupting the primary manufacturing process. Inferior or mismatched grinding equipment leads to irregular flakes, excessive dust (fines), and inconsistent material density, which can cause feeding issues, screw wear, and ultimately, defects in the final product. A high-quality industrial scrap grinder ensures consistent output, which translates directly into stable processing and superior product quality, enabling significant reduction in reliance on new raw materials. This strategic investment in robust industrial Plastic Recycling Equipment is crucial for maintaining profitability in competitive markets.

Customizing Your Solution: Granulator Selection by Application

Choosing the right Plastic Grinding Machine depends entirely on the type, volume, and geometry of the scrap you generate. The requirements for handling rigid, dense scrap differ dramatically from those needed for thin, voluminous waste. Understanding these nuances is key to selecting a machine that delivers maximum throughput and efficiency.

Grinder Machine for Injection Molding Units

Injection molding operations predominantly produce sprues, runners, and rejected small-to-medium-sized rigid parts made from polymers like ABS, Polycarbonate, PP grinding machine, and general-purpose PS. This scrap is generally dense and hard, requiring precise cutting action to prevent fragmentation and excessive heat generation.

For these lines, two types of machines are typically employed:

- Beside-the-Press Granulators (Low-Speed): These compact units, often considered a small plastic shredder machine alternative due to their slow rotational speed, are ideal for immediate, inline processing of sprues and runners as they are ejected. Their low-speed, high-torque action minimizes noise and dust while producing very uniform granules instantly for immediate reuse. They are perfect for materials requiring precise regrind size, such as high-tolerance medical or thin-walled consumer products.

- Central Granulators (Standard or Heavy-Duty): When scrap runners are collected from multiple presses, a Central Granulator is needed. These machines, capable of handling materials from PVC grinding machine to complex engineering plastics, feature robust open rotors and staggered blade designs, delivering higher throughput for central collection points.

Plastic Granulator for Blow Molding

Blow molding units, particularly those producing bottles, containers, and jerrycans, generate high volumes of light, hollow, and voluminous scrap, primarily in the form of flash (excess trim) and rejected parisons or finished products. These often involve materials like HDPE scrap crusher and PE granulator products. The geometry of this scrap presents a unique challenge: the material is light but bulky, which can lead to inefficient cutting or ‘floating’ in the cutting chamber.

The ideal Plastic Granulator for Blow Molding must feature:

- Large, Wide Feed Hoppers: To easily accept bulky, often lightweight, hollow materials without pre-cutting.

- Tangential or Horizontal Feed Design: This helps guide the large, hollow parts towards the cutting zone effectively.

- V-Cut Rotor Configuration: This knife arrangement provides a consistent shearing action across the entire width of the rotor, reducing energy consumption and operating noise, and preventing bridging of voluminous scrap. The robust construction ensures that even large, thick-walled HDPE scrap crusher parts can be handled reliably.

Grinding Solutions for Extrusion Units

Extrusion lines, which produce pipes, profiles, sheets, and films, generate a diverse range of scrap, from long, rigid start-up profiles and edge trims to very large, thick purgings and off-spec products. This demands the most versatile and durable Plastic Crusher Machine systems.

For high-volume, centralized recycling, a two-stage approach often proves the most efficient:

- Primary Size Reduction (Plastic Shredder and Grinder): For extremely large or thick components, such as thick-walled pipes or large purgings, a Plastic Shredder and Grinder combination is essential. The shredder, operating at low speed and high torque, tears the material into manageable chunks (pre-crushing), which are then fed into the high-speed granulator for final size reduction.

- Secondary Granulation (Heavy Duty Plastic Granulator): The final stage utilizes a Heavy duty plastic granulator with a deep cutting chamber, hardened tool steel knives (typically D2 or similar), and a powerful motor. These machines are engineered to handle continuous feed of thick, dense, and long scrap, ensuring the output material, or regrind, meets the stringent requirements for re-extruding into quality product. This full system forms the backbone of professional industrial Plastic Recycling Equipment setups.

Critical Design Features of a High-Performance Industrial Scrap Grinder

When evaluating industrial size reduction equipment, focusing on a few core design elements is critical for ensuring longevity, uptime, and optimal regrind quality. These features differentiate a mere grinder from a true Heavy duty plastic granulator.

1. Rotor and Blade Configuration

The heart of any Plastic Scrap Grinder is its cutting chamber. Look for rotors that are dynamically balanced and utilize high-grade, abrasion-resistant tool steel for the knives. The V-Cut or chevron blade geometry is widely considered superior because it draws the material into the centre of the rotor, resulting in less stress, uniform particle size, and lower energy spikes compared to straight-cut rotors. Furthermore, the ability to easily adjust the gap between the rotating and stationary knives is vital for maintaining cutting efficiency and avoiding damage, especially when processing varying polymer types.

2. Chamber Design and Durability

Industrial applications demand a robust machine. The cutting chamber should be constructed from heavy-gauge, wear-resistant steel, sometimes featuring replaceable wear plates, particularly for abrasive materials like filled plastics or PVC grinding machine products. An open-rotor design often aids in cooling and allows quick discharge of material, minimizing heat buildup and preventing degradation of temperature-sensitive polymers such as thin-film PE granulator scrap. A split, hinged cutting chamber design significantly improves accessibility, reducing the time required for cleaning, maintenance, and blade changes.

3. Noise and Dust Management

In a modern factory environment, noise and dust control are non-negotiable for operator well-being and regulatory compliance. High-speed grinding inherently generates noise. Look for machines that feature sound-dampening acoustic enclosures and advanced designs that minimize vibration. Furthermore, effective dust and fines management—often through integrated blower systems and cyclones—is crucial. Minimizing fines not only improves air quality but also ensures the resulting regrind is clean and easily processable, avoiding quality issues in subsequent melting stages.

Choosing the Right Partner: Expertise and Trust in Plastic Recycling Equipment

The machinery is only as good as the company that stands behind it. When investing in a Plastic Grinding Machine, you are seeking more than just hardware; you need a partner with deep expertise in plastic recycling technology.

It is here that the importance of specialized manufacturers becomes clear. For those seeking reliable, high-performance machinery engineered for the demanding Indian market, Invoitplast Machinery Best Plastic Scrap Grinder Machine Manufacturer & Supplier in India is recognized for delivering robust solutions. They understand the localized operational challenges—from power supply variability to the need for durable, low-maintenance designs—and focus on providing machines, including the Heavy duty plastic granulator and dedicated HDPE scrap crusher units, that maximize uptime and return on investment. Choosing a trusted manufacturer ensures access to prompt technical support, genuine spare parts, and the necessary application guidance to integrate the industrial Plastic Recycling Equipment seamlessly into your existing production flow. Their commitment to quality manufacturing and post-sales support builds the confidence needed for a long-term operational relationship.

Maximizing Profitability Through Precision Size Reduction

The success of your Injection Molding, Blow Molding, or Extrusion operation is fundamentally tied to the efficiency of your material management. Investing in the appropriate Plastic Scrap Grinder is a strategic decision that directly converts manufacturing waste into cost savings. Whether your need points toward a precise, low-speed Grinder Machine for Injection Molding or a powerful, large-volume Plastic Granulator for Blow Molding, the key is choosing equipment designed for consistency, durability, and minimal maintenance. By prioritizing high-quality design features and partnering with an established, expert supplier, you ensure that your Plastic Scrap Granulator becomes a reliable asset, maximizing material recovery and securing a sustainable, profitable future for your industrial plastic recycling efforts. The right machinery ensures your waste stream is clean, uniform, and instantly ready to return to production, closing the loop on material use efficiently and effectively.

Contact Us : +91 63546 0250 , info@invoitplast.com

FAQs

A Plastic Scrap Grinder Machine converts plastic scrap—such as runners, sprues, flash, purgings, trims, and rejected parts—into uniform regrind. It is essential because it reduces raw material costs, improves material utilization, enhances sustainability, and ensures consistent reprocessing quality across injection molding, blow molding, and extrusion units.

Industries such as injection molding, blow molding, extrusion, pipe & profile manufacture, sheet/film extrusion, WPC units, and general-purpose plastic recycling facilities benefit the most. Any plant generating plastic scrap in continuous volume requires a granulator to maintain productivity and reduce material wastage.

For injection molding units:

- Beside-the-Press Low-Speed Granulators → Best for inline grinding of sprues and runners.

- Central Granulators (Standard/Heavy Duty) → Best when scrap is collected from multiple machines.

Both options ensure clean, uniform regrind without excessive dust or heat buildup.

Blow molding scrap is lightweight, hollow, and voluminous (e.g., bottles, parisons, flash).

Machines with the following features work best:

- Large feed hoppers

- Tangential or horizontal feed

- V-cut rotor design

These prevent “floating” and ensure smooth cutting of HDPE and PE blow molding scrap.

Extrusion units require a two-stage grinding setup:

- Primary Shredder for pre-crushing large, thick, or rigid purgings.

- Heavy Duty Granulator for secondary size reduction into uniform regrind.

This setup ensures high throughput and protects the cutting chamber and blades from overload damage.

Look for:

- V-cut or Chevron Rotor (for energy-efficient, uniform cutting)

- Dynamically balanced rotor

- Hardened tool steel knives (D2 or equivalent)

- Adjustable knife gaps

These elements ensure long blade life, reduced fines, and consistent granule size.

Extremely important. A good cutting chamber:

- Minimizes heat buildup

- Prevents material clogging

- Ensures faster discharge of regrind

- Reduces downtime during cleaning

Features like hinged/split housings and replaceable wear plates significantly improve maintenance efficiency.

High-quality grinders should include:

- Acoustic sound-dampening enclosures

- Low-vibration rotor and frame design

- Integrated blower, cyclone, and dust separators

These ensure operator safety, better regrind quality, and compliance with factory standards.

Capacity depends on:

- Type of scrap generated

- Bulk density of material (HDPE vs PP vs ABS)

- Feed method (manual, conveyor, inline)

- Daily scrap volume

A simple rule:

Choose a granulator that handles 20–30% higher throughput than your current scrap load for future scalability.

- Frequent choking or chamber blockage

- Excessive dust (fines) or powdery output

- High noise levels and vibration

- Poor regrind consistency

- Overheating during continuous operation

- Rapid knife wear

Upgrading to a heavy-duty, industrial-grade machine prevents production losses.

Yes—provided the grinder produces uniform, clean, and dust-free granules. High-quality industrial scrap granulators ensure regrind suitable for direct reuse without compromising melt flow, surface finish, or mechanical strength.

Key safety features include:

- Interlocking safety switches

- Emergency stop buttons

- Overload protection

- Rotor brake systems

- Enclosed belt and pulley guards

These ensure safe operation in high-speed industrial environments.

Regular maintenance includes:

- Knife sharpening/replacement

- Cleaning of the cutting chamber

- Checking and adjusting blade gaps

- Lubricating bearings

- Ensuring dust removal systems are clear

Routine maintenance extends machine life and keeps output quality stable.

Price depends on:

- Motor capacity (HP)

- Rotor design (open, staggered, V-cut)

- Cutting chamber size

- Blade material and quantity

- Hopper design

- Additional features (sound enclosure, conveyor, blower, cyclone)

Heavy-duty granulators with advanced designs cost more but deliver higher ROI.

Invoitplast Machinery is known for:

- High-performance Heavy Duty Plastic Granulators

- Customized solutions for injection, blow molding, and extrusion industries

- Durable, low-maintenance designs suited for Indian factory conditions

- Reliable technical support and fast spare parts availability

- Expertise in complete Plastic Recycling Equipment systems

This makes Invoitplast Machinery one of the best Plastic Scrap Grinder Machine manufacturers & suppliers in India.