PVC Pulverizer Machine UAE

PVC Pulverizer Machine UAE

In the rapidly evolving landscape of the Gulf Cooperation Council (GCC) manufacturing sector, the demand for high-quality recycled polymer powder has never been higher. For industrial buyers, PVC processing plants, compound manufacturers, and WPC product innovators across Dubai, Abu Dhabi, and Sharjah, securing machinery that guarantees superior output and energy efficiency is paramount.

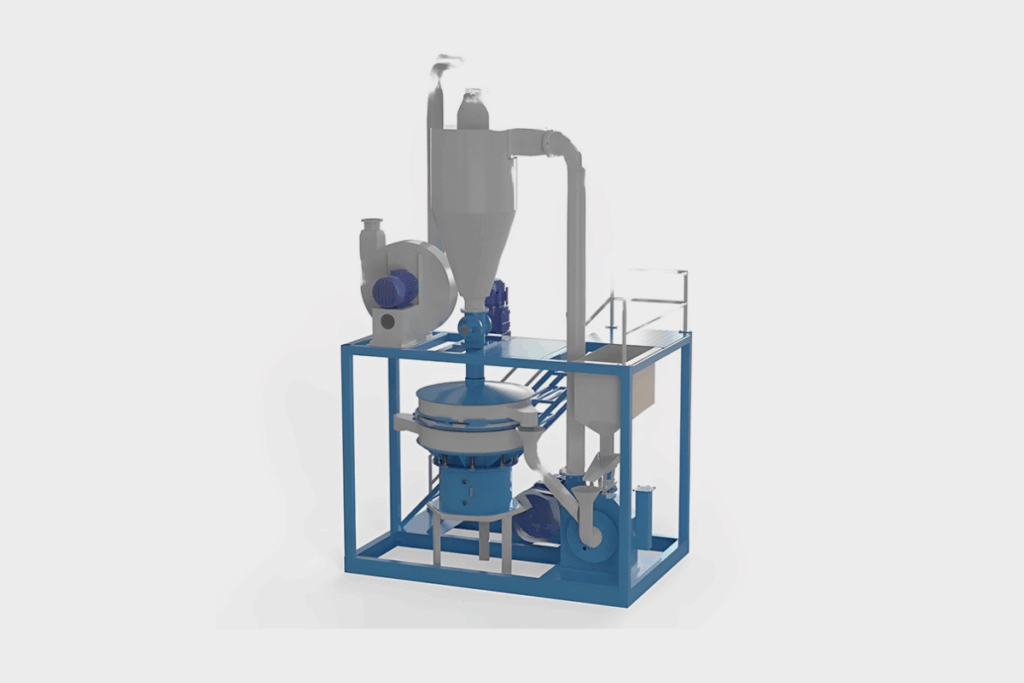

Invoit Plast Machinery PVT LTD, a globally recognized PVC Pulverizer Machine Manufacturer and dedicated Invoit Plast Machinery UAE Exporter, delivers the robust, high-throughput solutions the market demands. Our advanced PVC Pulverizer Machine UAE line is specifically engineered to convert PVC, CPVC, LLDPE, and HDPE scrap into fine, consistent powder—the essential raw material that fuels the region’s commitment to circularity and industrial growth.

Transforming Scrap into High-Value Powder: Why Quality Matters in the UAE

The United Arab Emirates is aggressively pursuing its Vision 2021 goals, with a heavy emphasis on sustainability and the circular economy. This has led to a major investment wave in local recycling infrastructure. For industrial operators, this shift is not just about environmental compliance; it is about maximizing resource value and reducing production costs.

The process of pulverization is the bottleneck or the catalyst for quality in plastic recycling. Inferior powder consistency leads to material degradation, inconsistent mixing, higher energy consumption, and increased product rejection in downstream processes like extrusion and moulding.

The Invoit Plast Plastic Pulverizer Machine UAE solves this challenge by ensuring an ultra-uniform particle size distribution (PSD) that is necessary for premium applications. Whether you are extruding high-pressure pipes in Jebel Ali, compounding specialised masterbatches in Sharjah, or manufacturing WPC profiles in Abu Dhabi, the quality of your powder dictates the quality and cost-efficiency of your final product.

We understand that in the competitive UAE market, performance is measured by reliability and ROI. This is why our technology goes beyond simple size reduction, offering a strategic asset designed for sustained operational excellence in the GCC’s challenging climate.

Technical Superiority: The Core of the Invoit PVC Pulverizer UAE

What sets the Invoit PVC Pulverizer UAE apart is the fusion of heavy-duty Indian engineering with features optimized for global performance standards, particularly the high-temperature, continuous-operation requirements of the Middle East. Our machines are more than grinders; they are precision attrition mills.

1. Advanced Disc Technology: The Heart of Consistency

The integrity of the final powder depends entirely on the grinding disc and chamber design.

- Precision-Machined Discs: We utilize high-grade, abrasion-resistant alloy steel, often incorporating German-grade material, which undergoes specialized hardening processes. This ensures exceptional blade longevity and minimizes wear, reducing maintenance downtime—a crucial factor for any PVC Pulverizer Supplier UAE serving high-volume operations.

- Optimal Geometry: The discs feature a unique, dynamically balanced serrated plate design that creates high-impact attrition. This method effectively fragments the plastic into powder without excessive thermal degradation, ensuring the polymer’s intrinsic properties are preserved.

- Gap Control: The gap between the stationary and rotary blades is micron-adjustable via precision adjustment bolts. This allows industrial users to precisely control the fineness of the powder (typically 20-80 mesh) to meet stringent specification requirements for various polymers, making it a versatile Plastic Pulverizer for PVC, CPVC, LLDPE, HDPE.

2. High-Efficiency Thermal Management System

Processing materials like PVC and LLDPE generates significant friction and heat, which, if not controlled, causes the polymer to melt, clump, and degrade. In the hot environment of the UAE, effective cooling is non-negotiable.

- Dual Cooling System: Every Invoit unit incorporates a robust dual-stage cooling provision—circulated water cooling within the main mill body and bearing housing, coupled with a high-capacity air-cooling blower.

- Temperature Monitoring: An automatic tripping system, coupled with precision temperature sensors at the mill output, ensures the machine stops if the temperature exceeds a predefined threshold. This safeguards the motor, prevents material damage, and ensures PVC Scrap Pulverizer Machine operation is thermally stable, even during non-stop, 24/7 cycles.

3. Safety, Automation, and Reliability

Invoit Plast believes operational safety and ease of use are cornerstones of a successful industrial partnership.

Feature | Technical Benefit | Operational Value (UAE Buyer) |

Hopper Magnet | High-efficiency magnetic separation at the feeding stage. | Protects the grinding discs from foreign metallic inclusions, preventing costly damage and ensuring product purity. |

Auto Loading System | Optional integration of flexible loaders and pre-grinders into a closed-loop system. | Minimizes manual intervention, reduces labor costs, and maximizes throughput capacity. |

Heavy-Duty Chassis | Reinforced structural steel frame, oversized bearings, and vibration control mounts. | Ensures minimal vibration during high-speed operation, guaranteeing machine longevity and stability under the high-load conditions typical of a UAE Plastic Recycling Machine. |

Low Energy Consumption | Optimized disc geometry paired with high-efficiency (IE3/IE4 standard) drive motors. | Significantly reduces the Total Cost of Ownership (TCO) and operating expense per kilogram of powder, directly enhancing profitability. |

Targeted Solutions for UAE Key Industrial Sectors

The Invoit Plast Plastic Pulverizer for PVC, CPVC, LLDPE, HDPE line offers dedicated models and configurations to meet the distinct material preparation requirements of the Gulf’s leading manufacturing clusters.

A. Pipe & Profile Extrusion (PVC & CPVC)

Targeting cable and pipe extrusion units, the quality of your PVC powder is the primary factor affecting the strength, surface finish, and dimensional stability of the final product.

- PVC Scrap Pulverizer Machine for Rigid Pipes: Our machines excel at processing rigid PVC pipe and profile scrap, delivering the precise mesh size required for smooth feeding into high-speed extruders. This consistent input is vital for meeting civil and industrial engineering standards for water and drainage systems across Dubai and Abu Dhabi’s massive infrastructure projects.

- CPVC Specialization: We offer specific configurations optimized for CPVC (Chlorinated Polyvinyl Chloride) recycling, handling its unique thermal and brittle characteristics to produce contaminant-free powder essential for fire-resistant and industrial piping applications.

B. Compound & Masterbatch Manufacturing (LLDPE & HDPE)

In the compounding industry, particle uniformity is non-negotiable for achieving perfect additive dispersion, color mixing, and final compound density.

- LLDPE Pulverization for Rotomoulding: For manufacturers producing water storage tanks in Sharjah and Roto-Moulded products, the machine provides a consistently fine LLDPE powder that ensures uniform wall thickness and reduces pinholes, directly impacting product integrity and yield rates.

- HDPE Recycling: Our technology effectively processes both rigid and flexible HDPE scraps, providing compounders with a reliable source of high-quality material powder for blending and reuse.

C. WPC and Construction Components

For the booming Wood Plastic Composite (WPC) industry, utilizing PVC waste material powder is a cost-effective path to durable, moisture-resistant building components. Our high-throughput models are designed to efficiently handle large volumes of post-industrial PVC Scrap Pulverizer Machine material, ensuring manufacturers can maintain a lean, green, and cost-competitive production line.

Invoit Plast Machinery UAE Exporter

While our manufacturing plant is strategically located in Ahmedabad, India—a global hub for precision engineering that ensures cost-efficiency—our operational focus is on seamless service and support for the UAE. We are not just a manufacturer; we are your dedicated PVC Pulverizer Supplier UAE partner.

Guaranteed Cost-Efficiency and Pricing Transparency

We understand that industrial buyers require clarity on investment. While the precise PVC Pulverizer Machine Price UAE depends on the model (e.g., PK-160, PK-200, or larger bespoke units), output capacity, and specific automation features (like auto-loading or advanced chilling), we guarantee two things:

- Superior TCO (Total Cost of Ownership): Our combination of low energy consumption, reduced maintenance frequency due to robust construction, and high throughput ensures the lowest cost per kilogram of pulverized material in the market.

- Clear Export Pricing: As an established Invoit Plast Machinery UAE Exporter, we offer transparent, DDP (Delivered Duty Paid) or CIF pricing to your facility in Dubai, Abu Dhabi, Ajman, or any free zone, simplifying the procurement process for your team.

End-to-End Logistical and Technical Support

Our commitment to UAE industrial buyers extends far beyond the sale:

- Technical Consultation: Our expert engineers work with your plant managers to analyze your specific material (PVC, CPVC, LLDPE, etc.), required mesh size, and daily capacity targets. We then recommend the perfectly sized machine (e.g., 200kg/hr, 500kg/hr, or 1000kg/hr models) to ensure optimal integration and throughput.

- Installation and Commissioning: We provide comprehensive assistance for installation and initial commissioning, ensuring your team is fully trained on operation, maintenance, and safety protocols.

- After-Sales Service: We maintain a ready inventory of critical spare parts, including grinding discs and blades, ensuring minimal downtime and rapid replacement logistics to keep your Plastic Pulverizer Machine UAE running continuously.

Final Assessment: Making the Investment Decision

Choosing a PVC Pulverizer Machine Manufacturer is a critical decision that impacts your long-term efficiency and product quality. Invoit Plast Machinery offers a compelling advantage: world-class precision engineering, designed for the rigorous demands of the GCC environment, backed by reliable, export-ready logistics and support.

Every component, from the high-HP motor drive system to the dust-free cyclone collector, is engineered for a single purpose: to provide the highest-quality polymer powder output at the lowest possible operational cost.

If your operation—be it pipe extrusion, compounding, or high-volume recycling—is hampered by inconsistent powder quality, high energy bills, or frequent machine downtime, the time to upgrade to an Invoit Plast PVC Pulverizer Machine UAE solution is now.

Secure Your Competitive Edge in the UAE Plastic Recycling Market.

We are ready to provide a detailed, customized quotation, capacity analysis, and TCO breakdown tailored to your specific facility.

Ready to Transform Your Recycling Operation?

As a leading PVC Pulverizer Supplier UAE, we invite industrial decision-makers, procurement teams, and plant managers across the Emirates to connect with our technical sales division. Discover the exact PVC Pulverizer Machine Price UAE for the model that meets your capacity needs.

Contact Invoit Plast Machinery PVT LTD—the trusted Invoit Plast Machinery UAE Exporter—and take the first step toward guaranteed powder consistency and superior operational efficiency.

Email : info@invoitplast.com

Phone Number : +91 63546 02502

FAQs

A PVC Pulverizer Machine converts PVC, CPVC, LLDPE, and HDPE scrap into fine, uniform powder required for extrusion, compounding, WPC manufacturing, and recycling applications. In the UAE, where high-output, energy-efficient recycling is crucial, a reliable pulverizer ensures consistent product quality and reduced material costs.

PVC Pulverizer Machines are widely used by:

- PVC & CPVC pipe manufacturers

- Masterbatch and compound manufacturers

- WPC profile and panel producers

- Rotomoulding units

- Plastic scrap recycling plants

- Cable and conduit extrusion units

These sectors depend on uniform powder for cost-efficient production.

Invoit machines are engineered with dual cooling systems (air + water), heat-resistant components, and automatic thermal cut-off features, ensuring stable operation even in high-temperature UAE environments like Dubai, Abu Dhabi, and Sharjah.

The machine delivers precise powder output ranging from 20 to 80 mesh, adjustable using micron-level gap control. This supports applications like pipe extrusion, compounding, rotomoulding, and WPC production.

Invoit Plast offers capacities from 200 kg/hr to 1000+ kg/hr, depending on the model, material type, disc design, and optional automation like auto-loading systems.

PVC Pulverizer Machine Price UAE varies based on model size (PK-160, PK-200, PK-300), output capacity, disc material, motor rating, and automation features. Invoit Plast provides transparent CIF and DDP pricing directly to Dubai, Abu Dhabi, Sharjah, Ajman, and UAE free zones.

Yes. As a dedicated Invoit Plast Machinery UAE Exporter, the company provides full installation guidance, commissioning support, operator training, and technical documentation to ensure smooth plant integration.

The machine efficiently processes:

- PVC

- CPVC

- LLDPE

- HDPE

- WPC and composite scrap

Its advanced disc technology ensures uniform powder for multiple industrial applications.

Invoit Plast machines use high-efficiency IE3/IE4 motors, precision disc geometry, dual cooling, and optimized airflow to reduce power consumption. This directly lowers the Total Cost of Ownership (TCO) and cost per kilogram of powder—critical for UAE recycling operations.

Absolutely. The company maintains a ready stock of critical spare parts like grinding discs, blades, magnets, and bearings, ensuring fast delivery and minimal downtime. Ongoing technical support is available for all UAE customers.

Buyers in Dubai, Sharjah, Jebel Ali, and Abu Dhabi can contact the Invoit Plast UAE Export Desk for:

• Detailed technical sheets

• Capacity recommendations

• Price quotations

• Shipping and installation support

• Material testing and performance benchmarks