Plastic Scrap Grinder Machine Supplier in UAE

Plastic Scrap Grinder Machine Supplier in UAE

Elevating Industrial Recycling Standards Across the Emirates

The United Arab Emirates—spanning the industrial hubs of Dubai, Abu Dhabi, Sharjah, and the growing manufacturing zones of Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain—is rapidly cementing its position as a global leader in sustainable industrial practice. Driven by the ambitious Operation 300bn strategy and the comprehensive UAE Circular Economy Policy 2021-2031, the imperative for efficient, high-capacity, and reliable polymer processing machinery has never been more critical.

For polymer processors, sophisticated recycling plants, and high-volume manufacturers across the Emirates, managing waste streams is no longer a peripheral concern; it is a core profitability and compliance mandate. The foundation of successful polymer recycling rests entirely on the quality and consistency of size reduction. If your existing equipment is bottlenecking throughput, suffering from excessive downtime, or failing to produce the uniform regrind required for high-tolerance applications, your operational efficiency is compromised.

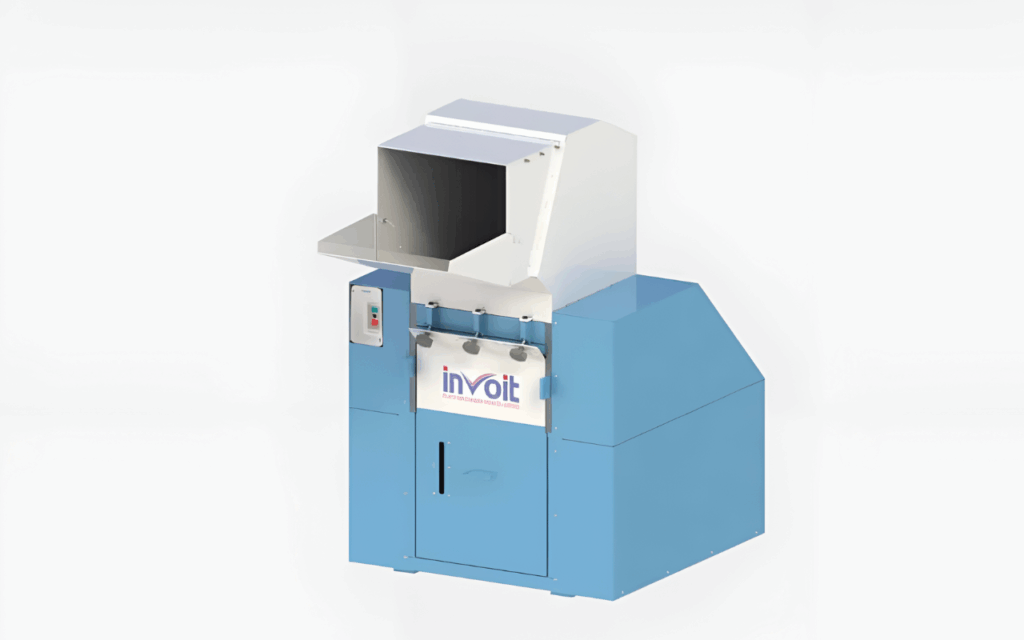

Invoit Plast Machinery Pvt. Ltd., based in Ahmedabad, India, stands as the premier Plastic Scrap Grinder Machine Supplier in UAE, offering heavy-duty, meticulously engineered recycling solutions designed to meet the rigorous demands of the Gulf’s 24/7 industrial environment. We provide the robust and precision-focused Plastic Scrap Grinder Machine UAE facilities require to convert diverse plastic waste—from large rotomolding rejects to delicate film and rigid purgings—into high-quality, reusable material. We don’t just supply machinery; we deliver the foundational technology that enables the UAE’s transition to a truly circular manufacturing model.

UAE Market Needs: Addressing Polymer Processing Pain Points in Dubai and Abu Dhabi

Industrial leaders in the UAE face unique challenges that demand specialized recycling equipment. The high cost volatility of virgin polymers, coupled with the national push for waste diversion and the phased bans on single-use plastics, makes in-house recycling and material recovery essential for maintaining competitive advantage and regulatory compliance.

The Critical Need for a High-Performance Plastic Scrap Crusher UAE

Industrial leaders in the UAE face unique challenges that demand specialized recycling equipment. The high cost volatility of virgin polymers, coupled with the national push for waste diversion and the phased bans on single-use plastics, makes in-house recycling and material recovery essential for maintaining competitive advantage and regulatory compliance.

Key Pain Points Driving Demand for Invoit Plast Machinery:

- High Downtime and Maintenance: Inferior crushers fail under the pressure of handling thick-walled plastics common in rotomolding and heavy piping, leading to frequent blade changes, screen blockages, and costly production halts.

- Inconsistent Regrind Quality: For compounders and rotomolders, the uniformity of the regrind is paramount. Poorly sized or excessively dusty material cannot be reintroduced into high-spec product lines without compromising quality.

- Energy Inefficiency: Older Plastic Waste Grinder Machine units consume excessive power relative to output, directly impacting operational expenditure in high-utility cost environments like Dubai and Abu Dhabi.

- Handling Diverse Waste Streams: Modern UAE factories handle everything from PET bottles (in Fujairah and Ajman packaging units) to massive LLDPE tanks (in the rotomolding sector). A single, versatile, and dependable Industrial Plastic Grinder Machine is essential for consolidating operations.

Our solution is a precision-engineered size reduction system—a purpose-built Plastic Scrap Grinding Machine that transforms heterogeneous waste into homogenous, reusable flakes, eliminating the “recycling compromise” and ensuring your regrind is as valuable as your virgin pellet.

Why Invoit Plast is the Leading Plastic Scrap Grinder Machine Supplier in UAE

Invoit Plast Machinery Pvt. Ltd. operates as a manufacturer-exporter, offering a strategic advantage to industrial buyers in the UAE. By sourcing directly from our state-of-the-art facility in Ahmedabad, you bypass unnecessary multi-tiered supply chains, securing high-caliber Indian engineering tailored for international performance standards.

The Invoit Advantage for UAE Commercial Buyers

Choosing Invoit Plast means partnering with a manufacturer deeply familiar with the logistical and performance requirements of the Gulf region. We understand that machinery operating in Jebel Ali, Khalifa Port, or industrial areas of Sharjah and Ras Al Khaimah must withstand high ambient temperatures and intensive operational cycles.

- Direct Manufacturer Transparency & Value: We offer direct factory pricing and support, ensuring you receive the highest component quality and the most competitive Total Cost of Ownership (TCO) in the Plastic Recycling Machine UAE market.

- Engineering for Heat and Durability: Our machines feature over-engineered cooling systems, robust V-Cut rotor geometry, and specialized metallurgy in the cutting chamber, designed to mitigate the thermal stress generated during high-speed grinding—a critical factor for sustained operation in the UAE climate.

- Seamless Export and Logistics Expertise: As a seasoned exporter to the Middle East, we manage the entire logistics chain, ensuring prompt, professional delivery and documentation for smooth customs clearance into all major Emirates.

- Proven Middle East Performance: Our industrial-grade systems are already successfully deployed across the GCC, proving our capability to act as the Best Plastic Scrap Grinder Supplier UAE buyers can rely on for long-term reliability.

Key Advantages: Engineering the Heavy-Duty Scrap Grinder for UAE Reliability

Our Heavy-Duty Scrap Grinder for UAE operations is built on a foundation of unyielding mechanical integrity and precision engineering, directly translating into superior operational performance and maximized return on investment (ROI) for factory owners and technical managers.

1. Unmatched Throughput and Power Efficiency

Our granulators are designed to maximize output per kilowatt hour. The meticulously calculated rotor-to-chamber ratio and optimized fly-wheel mass ensure that kinetic energy is efficiently utilized to shear material, reducing energy spikes and overall consumption.

- High Inertia Rotor: Provides smooth, continuous grinding, even when processing challenging, thick-walled materials like IBC tanks or heavy pipe remnants.

- Precision Cutting Gap: Factory-set and easily adjustable blade alignment ensures a consistently tight cutting gap, maximizing material shear force and minimizing power loss and material stress.

2. Superior Regrind Quality for Value Maximization

The core function of a quality grinder is to deliver uniform, low-dust regrind. Our machines guarantee a particle geometry perfectly suited for reintroduction into primary production lines, which is crucial for Plastic Scrap Grinder for Rotomolders / Recyclers / Polymer Units in UAE.

- Uniform Flake Size: The cutting pattern, combined with custom-specified screen aperture, ensures flake size distribution is extremely tight, preventing segregation in the hopper and ensuring consistent melt flow during re-processing.

- Minimised Fines and Dust: Reduced thermal stress and optimised chamber design lower the generation of unwanted “fines,” preserving the polymer’s intrinsic value and reducing atmospheric pollution within the factory.

3. Reduced Total Cost of Ownership (TCO) and Maintenance

We engineer our machines for longevity and ease of service, factors that significantly drive down long-term ownership costs compared to cheaper alternatives.

- Segmented and Reversible Blades: Cutting blades are designed for multiple rotations and easy access, dramatically extending blade life and simplifying maintenance schedules.

- Hydraulic Chamber Access: Large, hydraulic opening access to the grinding chamber allows for rapid, tool-free access to the rotor and screen, cutting cleaning and service time from hours to minutes.

- Isolation of Bearings: Heavy-duty outboard bearings are isolated from the cutting chamber, preventing polymer dust and debris contamination, which is the leading cause of premature bearing failure and machine seizure.

4. Safety and Automation Built for Compliance

Safety and modern controls are paramount in UAE’s highly regulated industrial environments. Our Industrial Plastic Grinder Machine units comply with international safety standards and are designed for operator protection and integration with automated feeding systems.

- Interlocked Safety Systems: The machine cannot operate if the cutting chamber is not fully secured, protecting personnel during maintenance.

- Integrated Metal Detection: Optional magnetic separation and metal detection systems safeguard the machine and the integrity of the polymer stream from ferrous and non-ferrous contaminants.

Industry-Specific Solutions: Tailored Grinders for the UAE Polymer Sector

The diversity of the UAE’s manufacturing base—from the specialized rotomolding facilities in Ajman to the massive packaging plants in Dubai and Abu Dhabi—requires a grinder designed not just for plastic, but for specific polymers and applications. Invoit Plast delivers application-focused machinery that ensures specialized success.

I. Rotomolders and Tank Manufacturers (LLDPE, HDPE)

Rotomolding facilities dealing with large, hollow articles (tanks, barriers, water barrels) generate bulky, thick-walled scrap and heavy purgings that overwhelm standard granulators.

- Solution: Wide-mouth, heavy-duty granulators with specialized, high-torque rotors capable of drawing in and cleanly processing large, odd-shaped sections of LLDPE and HDPE without jamming or bridge formation.

- Benefit: Achieves the ultra-fine, uniform powder required for smooth rotomolding cycles, ensuring zero black specks and perfect color dispersion when reintroducing regrind. This makes us the reliable Plastic Scrap Grinder for Rotomolders in UAE.

II. Material Recovery Facilities (MRFs) and Recycling Plants (PET, PP, Film)

Recyclers handling post-consumer and post-industrial waste require reliability and capacity when processing materials like baled PET bottles, PP containers, and flexible film waste from the vast consumer markets in Dubai and Sharjah.

- Solution: High-capacity, multi-knife rotor designs optimized for high-volume film and bottle grinding, often integrated directly with washing and drying lines.

- Benefit: Continuous, non-clogging operation necessary for high-volume Plastic Recycling Machine UAE lines, drastically increasing the output volume of clean, saleable flake. We are the trusted Plastic Scrap Grinder for Recyclers in UAE.

III. Injection & Blow Molding Factories (HDPE, PP, PS)

These facilities generate sprues, runners, and defective parts—often rigid and abrasive. Their priority is instantaneous, high-quality, closed-loop recycling to minimize waste and ensure material quality.

- Solution: Soundproofed, near-press granulators designed for quiet, continuous operation and rapid, automated material feeding directly back to the press or extruder.

- Benefit: Enables immediate, closed-loop processing, significantly reducing virgin material consumption and handling costs, improving the financial metrics for plastic parts manufacturers across the Emirates.

IV. Polymer Compounders and Masterbatch Units

Compounders require the highest level of size consistency and freedom from thermal degradation, as their regrind feeds specialized, high-value products.

- Solution: Granulators equipped with highly precise screens and enhanced cooling jackets to ensure the polymer is processed at the lowest possible thermal profile, preserving molecular integrity and additive packages. We are the trusted Plastic Scrap Grinder for Polymer Units in UAE.

- Benefit: Guarantees that the reprocessed material meets the stringent quality specifications required for high-end masterbatch and engineering polymer applications, maximizing the value of the scrap stream.

Supporting the UAE Sustainability and Circular Economy Goals

The UAE vision, defined by the Dubai Waste Management Strategy 2041 and the national commitment to Net Zero 2050, places unprecedented demands on the industrial sector to transition from a linear to a circular model. Investing in a leading Plastic Scrap Grinder Machine UAE solution from Invoit Plast is a direct, measurable step toward achieving these crucial national targets.

Operationalizing Sustainability: Efficiency Meets Ecology

Our machinery is an enabler of the circular economy, providing the critical first step in resource recovery. By empowering factories in Fujairah, Umm Al Quwain, and across the Emirates to reprocess 100% of their production waste, we facilitate:

- Landfill Diversion: Drastically reducing the volume of material sent to landfill, aligning directly with the governmental mandates in Abu Dhabi and Sharjah for waste minimization.

- Carbon Footprint Reduction: Utilizing in-house recycled content requires significantly less energy than producing new virgin plastic, supporting the UAE’s climate action commitments.

- Cost Stabilization: Reducing reliance on external material markets and transportation, offering a predictable, high-quality raw material source derived directly from your own waste stream.

- Regulatory Alignment: Demonstrating proactive compliance with the increasing scope of environmental regulations, positioning your factory as a responsible and sustainable industry leader.

Why Choose India-Manufactured Machinery from Invoit Plast

Invoit Plast Machinery Pvt. Ltd., as a leading manufacturer and exporter from Ahmedabad, India, provides a synthesis of superior engineering, value, and customer-centric support that competitors struggle to match. Our commitment extends beyond the point of sale, offering lifecycle value to your operation.

Advanced Engineering at a Competitive Advantage

Our Plastic Scrap Grinding Machine technology is rooted in decades of expertise, leveraging best-in-class Indian manufacturing precision. We combine globally recognized design principles (like heavy-duty welded construction and optimal cutter geometry) with a cost structure that ensures exceptional value.

- Engineering Reliability: Our engineering philosophy is based on over-specifying components (heavier frame, larger bearings, robust drive trains) to guarantee high operational uptime, particularly crucial in demanding applications like the Plastic Scrap Crusher UAE market.

- Customization and Adaptation: Unlike standard, off-the-shelf imports, we maintain the flexibility to customize aspects like feeding hoppers, discharge conveyors, and control systems to perfectly integrate with your existing UAE factory layout and specific material requirements.

- Dedicated After-Sales Support: Our export model includes clear protocols for rapid dispatch of wear parts (blades, screens, drive belts) and remote or in-person technical assistance, minimizing any risk associated with international sourcing. We ensure that your Heavy-Duty Scrap Grinder for UAE remains operational and optimized.

Securing Your Future with the Right Industrial Plastic Grinder Machine

In the competitive and rapidly evolving industrial landscape of the United Arab Emirates, operational efficiency, regulatory compliance, and raw material security are non-negotiable. The transition to a circular economy is not merely a trend—it is a mandatory shift in manufacturing strategy. The reliable, high-performance processing of your polymer waste is the single most important factor in securing a sustainable, profitable future.

Invoit Plast Machinery Pvt. Ltd. is committed to being the long-term partner for every polymer processor, recycler, and industrial buyer seeking the definitive Plastic Scrap Grinder Machine Supplier in UAE. From the petrochemical giants in Abu Dhabi to the agile packaging firms in Ajman and Ras Al Khaimah, our Industrial Plastic Grinder Machine solutions provide the precision, durability, and operational excellence demanded by the Gulf market.

Don’t let inefficient size reduction erode your margins and compromise your product quality. Invest in the best. Invest in Invoit Plast.

Ready to Optimize Your Recycling Line and Maximize Polymer Value?

Take the essential step toward superior operational efficiency and compliance in the UAE. Our team of polymer processing experts is ready to conduct a detailed analysis of your material, throughput needs, and facility layout to specify the perfect Plastic Waste Grinder Machine solution tailored for your specific factory location—be it in Dubai, Sharjah, Fujairah, or Umm Al Quwain.

Connect with Invoit Plast Today. Stop Grinding Money, Start Grinding Profit.

Click Here to Request a Complimentary, Customized Consultation and Specification Proposal for Your UAE Facility.

Inquire Now for the Best Plastic Scrap Grinder Supplier UAE Trust.

Invoit Plast Machinery Pvt. Ltd. | Ahmedabad, India | Manufacturer & Global Exporter of Plastic Recycling Solutions

Email : info@invoitplast.com

Phone Number : +91 63546 02502

FAQs

Invoit Plast Machinery Pvt. Ltd. is a direct manufacturer-exporter delivering heavy-duty, precision-engineered plastic scrap grinders tailored for UAE recycling needs. Our machines are built for 24/7 operation, high throughput, and extreme durability—ideal for Dubai, Sharjah, Abu Dhabi, Ajman, Ras Al Khaimah, and Fujairah industries.

Our grinders are widely used by rotomolders, recyclers, polymer processors, injection and blow molding factories, packaging companies, MRFs, and masterbatch/compound units across the Emirates. Any facility generating plastic scrap—LLDPE, HDPE, PP, PET, film, rigid parts—can benefit from our machines.

Yes. Invoit Plast produces heavy-duty wide-mouth rotomolding grinders designed specifically for bulky LLDPE/HDPE tank scrap, purgings, and large hollow components. These machines offer high torque, anti-bridging design, and superior cooling for efficient size-reduction without jamming.

Our machines can process:

- LLDPE, HDPE, LDPE

- PET, PP, PS, ABS

- Film, bottles, rigid parts

- Injection sprues, blow molding scrap

- Rotomolding waste

This versatility makes us the best Plastic Scrap Grinder Supplier UAE factories rely on for multi-material recycling.

Yes. We customize hopper size, rotor type, knife configuration, screen size, discharge options, and automation integration based on the specific material and layout of your UAE facility. Custom designs ensure maximum throughput and seamless integration into existing recycling lines.

Our grinders enable UAE factories to recycle 100% of in-house waste, reduce landfill usage, cut carbon emissions, and reintroduce high-quality regrind into production. This directly supports UAE sustainability mandates, waste diversion goals, and Net Zero 2050 targets.

Invoit Plast machines are built with:

- Over-engineered cooling systems

- Heat-resistant metallurgy

- Heavy-duty rotor design

- Outboard bearings

- Segmented and reversible blades

These features ensure performance even in high-temperature industrial environments like Dubai and Abu Dhabi.

Absolutely. Our machines feature optimized rotor geometry, balanced flywheel inertia, and precision cutting gaps to reduce power consumption while delivering maximum output. UAE buyers experience significantly lower operational costs compared to older grinder models.

Yes. We specialize in Middle East exports and ensure fast shipment, complete documentation, customs clearance support, and quick delivery to all Emirates. We also provide lifetime technical support, spare parts supply, and remote assistance.

UAE buyers should consider scrap type (film, rigid, rotomolding, PET), desired output size, required throughput, factory layout, and energy efficiency. Invoit Plast offers free technical consultation, evaluates your material samples, and recommends the ideal Plastic Waste Grinder Machine tailored to your factory’s needs.