Applications of PVC Pulveriser in the Plastic Industry

In the modern plastic manufacturing ecosystem, one machine plays a silent yet powerful role in the efficiency, quality, and scalability of plastic production processes — the PVC Pulveriser Machine. As the demand for plastic products grows across sectors like packaging, construction, automotive, and healthcare, the need for recycling and reusing plastic material efficiently has become more crucial than ever. This is where PVC pulverisers step in as an essential part of plastic recycling and material preparation.

What is a PVC Pulveriser Machine?

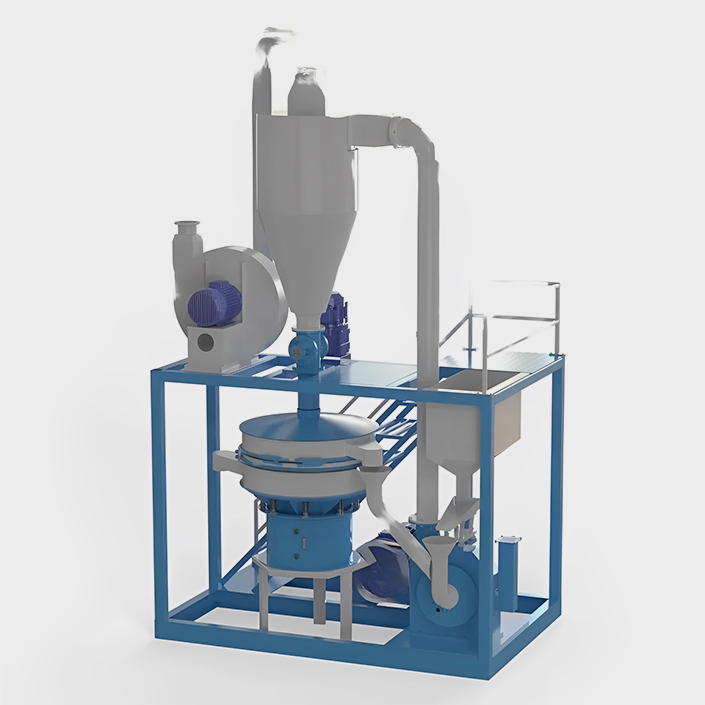

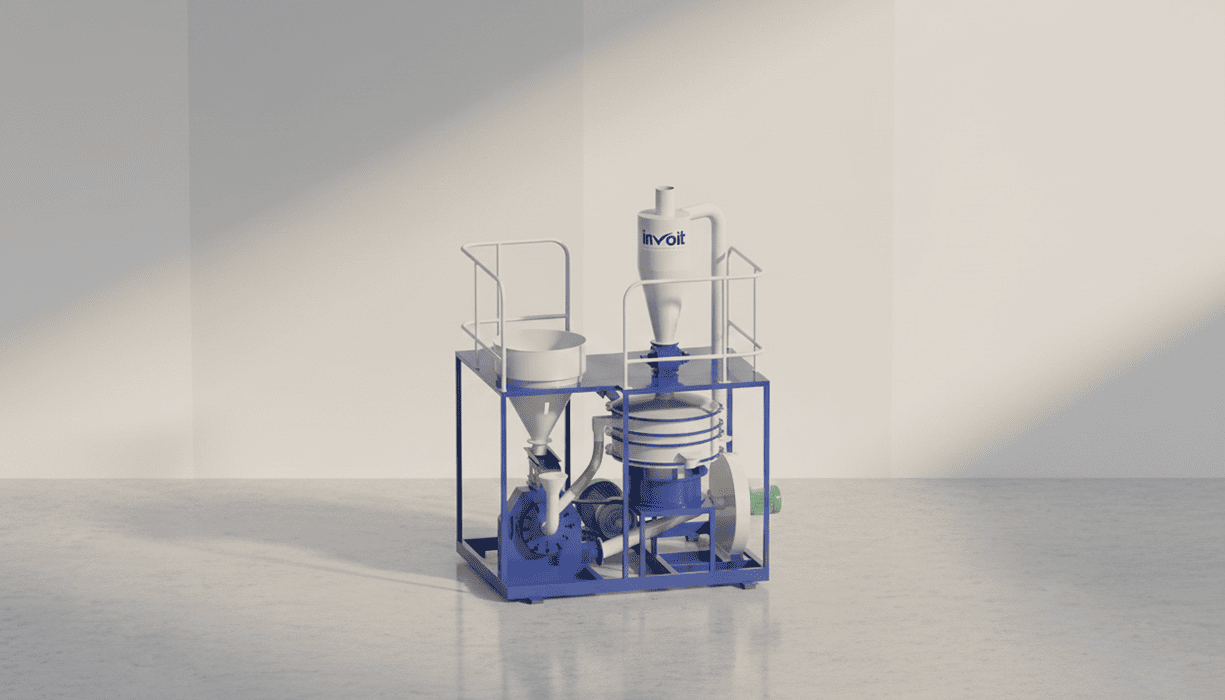

A PVC Pulveriser Machine is a type of Plastic Pulverizer Machine specifically designed to grind and crush PVC plastic material into fine powder. These machines are engineered to convert plastic scrap, rejected parts, or virgin PVC resins into finely ground powder which can then be reused in the manufacturing process.

PVC pulverisers usually consist of a high-speed rotating disc, fixed disc, cooling system, hopper, and powder collector. The precision in the grinding process ensures that the final product — the plastic powder — is consistent in size and texture, making it ideal for reprocessing or direct molding applications.

Role of PVC Pulverisers in the Plastic Industry

The plastic industry depends heavily on machines that can process raw and scrap materials into usable forms. Pulverisers are pivotal in this workflow, particularly in transforming bulky plastic waste into fine powder — thus closing the loop of plastic usage and minimizing waste. Let’s now explore the wide range of applications that a Plastic Pulverizer Machine — especially a PVC-specific one — serves within the plastic industry.

PVC Pipe Manufacturing and Recycling

PVC pipes are widely used in the plumbing and construction industry. During production, there is a significant amount of PVC waste generated in the form of pipe trimmings, defective sections, or startup scrap. A PVC Pulverizer Machine is used to grind this scrap back into a powder that matches the original specifications.

This recycled PVC powder can then be reintegrated into the extrusion process, reducing raw material costs and minimizing waste. This closed-loop recycling model not only enhances sustainability but also lowers operational costs for PVC pipe manufacturers.

Production of Plastic Sheets and Films

PVC is also widely used for making sheets and films for packaging, signage, and industrial applications. The manufacture of these sheets often results in leftover trimmings and defective batches. With the help of a Plastic Pulverizer Machine, these materials can be pulverized into fine particles and reused without compromising the quality of the final product.

In many modern manufacturing setups, the Plastic Powder Machine is integrated with sheet production lines to allow real-time recycling of scrap material, improving both efficiency and eco-friendliness.

Cable Insulation and Wiring Applications

PVC is a preferred material for cable insulation due to its excellent thermal and electrical properties. However, cable manufacturing generates a lot of rejected material, especially during startup or color changes. Pulverizing this material using a PVC Pulverizer Machine allows cable manufacturers to recover valuable PVC resin in powder form, which can then be reused in subsequent batches.

This approach significantly cuts down on raw material waste and aligns with industry standards that emphasize sustainable and efficient manufacturing.

Plastic Flooring and Wall Panel Production

PVC is commonly used in the interior design industry, especially for making flooring tiles and wall panels. During the production of these items, edge trims and rejected tiles are generated. Using a Plastic Pulverizer Machine, this waste material can be converted back into powder for reuse in production.

Additionally, the use of Plastic Powder Machines allows manufacturers to maintain color consistency and uniformity across batches by reintroducing powdered scrap into the production mix.

Blow Molding and Injection Molding Regrind Processing

While blow molding and injection molding are often associated with HDPE and PP plastics, there are various products that also use PVC — such as containers, jars, caps, and custom-molded items. During molding, the runners, sprues, and rejected parts are often ground using a PVC Pulverizer Machine.

This ground powder can be reused, reducing dependency on virgin materials and controlling costs. The fine and uniform nature of the powdered PVC also ensures smooth flow during re-molding processes.

WPC (Wood Plastic Composite) Manufacturing

Wood Plastic Composite (WPC) is a rapidly growing segment in the plastic industry, combining the benefits of both plastic and wood. PVC-based WPC products, such as decking and cladding, require finely powdered PVC to bind with wood fibers.

Here, PVC Pulveriser Machines are critical as they help prepare PVC in the right form and consistency to mix efficiently with wood powder. This blend is then processed through extrusion or molding to create eco-friendly and durable WPC materials.

Masterbatch and Compounding Processes

Masterbatch manufacturers and compounders use a blend of polymers, additives, and colorants. To create a high-quality and homogeneous mixture, the base polymer, such as PVC, must be in powdered form. The Plastic Pulverizer Machine plays a key role in preparing this base material, ensuring the powder size is consistent and free from contaminants.

This not only helps in achieving uniform dispersion of additives and pigments but also supports high-throughput production in compounding lines.

Plastic Recycling and Waste Management Industry

Recycling is one of the most important and rapidly growing applications of PVC Pulverizer Machines. With stricter regulations on plastic waste and growing awareness about environmental sustainability, recycling plants and plastic waste processors are increasingly investing in pulverisers.

Whether it’s post-industrial scrap or post-consumer waste, these machines convert unusable plastic into valuable powder that can be sold or used in secondary manufacturing processes. By adopting Plastic Pulverizer Machines, recycling firms can maximize their output quality and increase profitability.

Support for Circular Economy Initiatives

PVC pulverisers not only help individual manufacturers save costs but also promote industry-wide adoption of circular economy practices. As more businesses embrace the concept of “reduce, reuse, recycle,” the demand for efficient Plastic Powder Machines continues to grow.

By integrating pulverisers into their production lines, companies ensure minimal material wastage and reduced landfill contributions, creating a more sustainable business model.

Choosing the Right PVC Pulveriser for Your Application

Different industries have different pulverizing needs — from powder fineness and throughput to temperature sensitivity and material type. A high-quality PVC Pulverizer Machine must be robust, energy-efficient, and capable of delivering consistent performance under heavy-duty usage.

This is where Invoit Plast Machinery PVT Ltd stands out as the best PVC Pulveriser Machine manufacturer in India. With state-of-the-art technology, excellent customer support, and years of experience in plastic processing machinery, Invoit Plast offers customized solutions that cater to the unique needs of various plastic industries. Their machines are built for durability, performance, and precision, making them ideal for both small-scale processors and large industrial manufacturers.

Final Thoughts

From pipe and sheet production to compounding and WPC manufacturing, PVC Pulveriser Machines have become an indispensable asset in the plastic industry. These machines not only contribute to cost-effective manufacturing but also align with modern sustainability goals by reducing waste and promoting recycling.

Whether you’re a plastic product manufacturer, a recycler, or a compounder, investing in a high-quality Plastic Pulverizer Machine or Plastic Powder Machine can dramatically improve your operational efficiency and environmental impact. And when it comes to reliability, innovation, and industry expertise, Invoit Plast Machinery PVT Ltd continues to lead the way as the most trusted name in the PVC pulveriser market in India.

FAQs

A PVC Pulveriser Machine is used to grind PVC plastic into fine powder, enabling reuse in manufacturing PVC pipes, sheets, films, and other plastic products.

Yes, they are widely used in plastic recycling to convert industrial scrap and rejected PVC parts into reusable plastic powder for reprocessing.

Industries such as pipe manufacturing, cable insulation, WPC production, flooring, injection molding, and recycling benefit from these machines.

Both refer to machines that grind plastic into powder. "Plastic Pulverizer" focuses on the grinding function, while "Plastic Powder Machine" emphasizes the output.

Invoit Plast offers high-quality, efficient, and durable PVC Pulveriser Machines backed by excellent support, making them the best manufacturer in India.

Yes, the powder is uniform and fine enough to be used directly in extrusion, molding, or compounding processes without compromising quality.

Do these machines work only with PVC or other plastics too?