Boost Your Production Line Efficiency with a Reliable Screw Conveyor from Invoit Plast

In the demanding landscape of modern manufacturing, efficiency is the ultimate competitive advantage. For companies dealing with dry bulk materials—be it powders, granules, pellets, or flakes—the weakest link often lies not in the processing machinery, but in the material handling systems connecting them.

Lagging conveyors, frequent jams, dust contamination, or high maintenance costs can quickly erode profit margins and halt productivity. When downtime costs thousands of dollars per hour, the decision of which material handling equipment to purchase becomes a critical strategic investment, not just a procurement expense.

This is where the reliability and robust engineering of a high-quality Screw Conveyor system from a trusted Screw Conveyor System Manufacturer like Invoit Plast becomes non-negotiable. We understand that our customers require seamless, dust-free, and energy-efficient transfer systems that deliver consistent throughput, year after year. For manufacturers across India looking for the best in class, understanding the Invoit Plast advantage is the first step toward guaranteed operational excellence.

The Economic Impact of a Superior Screw Conveyor

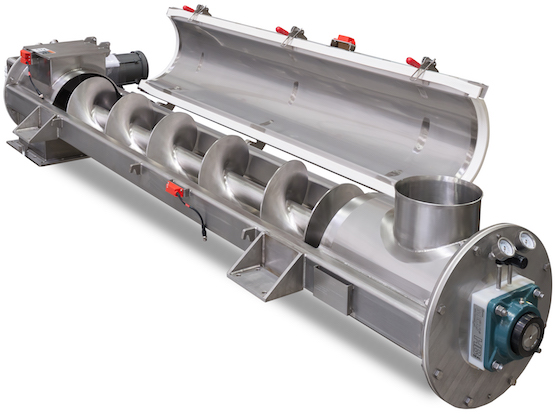

The humble Screw Conveyor—a testament to Archimedes’ genius—remains the backbone of bulk material transport in countless industries. However, modern industrial applications demand more than just moving material from Point A to Point B; they require precision, hygienic handling, and minimal operational expenditure.

For a B2B buyer, the intent isn’t just to purchase a machine, but to acquire a solution that reduces Total Cost of Ownership (TCO) and guarantees uptime. A superior conveyor system offers key economic benefits:

- Minimized Spillage and Contamination: The enclosed nature of a screw conveyor ensures product integrity, which is paramount in sensitive industries like food processing or plastics.

- Reduced Labor Dependency: Automated, continuous material flow eliminates the need for manual transport, freeing up valuable personnel for higher-value tasks.

- Space Optimization: Especially when compared to pneumatic or belt systems, a screw conveyor often features a smaller, more compact footprint, making it ideal for integration into existing, space-constrained production facilities.

When you invest in a solution from a reputable Screw Conveyor Manufacturer, you are securing a commitment to engineering standards that directly translate into operational savings.

Engineered for Flow: Mastering the Horizontal Screw Conveyor

While various orientations exist, the Horizontal Screw Conveyor is arguably the workhorse of industrial material handling. Its design simplicity, combined with high efficiency, makes it the standard for moving material over short to moderate distances within a facility.

Precision in Design and Functionality

The effectiveness of a horizontal unit hinges entirely on its construction:

- Trough and Flighting Integrity: The relationship between the trough and the helical flighting must be optimized for the specific material. Invoit Plast analyzes particle size, density, flowability, and abrasion potential to specify the exact pitch, diameter, and clearance required for maximum fill and minimum wear.

- Bearing Placement and Seal Design: For horizontal applications, intermediate hanger bearings are often necessary. Invoit Plast employs robust, self-lubricating bearings and advanced sealing technology (like lantern rings and packing glands) to prevent product leakage and ingress of foreign contaminants, ensuring a clean and reliable system.

- Drive Configuration: Utilizing direct-drive or heavy-duty chain drives, Invoit Plast ensures power transmission is efficient, with motors and gearboxes selected to handle peak loads without overheating or premature failure—a critical factor for continuous 24/7 operation.

Choosing an engineered Horizontal Screw Conveyor means investing in a machine designed to eliminate the common pain points of material bridging and bearing failure, thereby significantly boosting line efficiency.

Screw Conveyors for the Plastics Industry

The plastics industry presents unique challenges for material handling. Whether dealing with virgin resins, compounding additives, or the complex materials generated during recovery, systems must handle highly abrasive, varying density, and often static-prone materials. For companies focused on sustainability, the efficiency of recycling operations is key.

Invoit Plast Machinery is highly focused on providing specialized solutions for this demanding sector, offering both the Plastic Screw Conveyor and the robust Plastic Recycling Conveyor.

The Dedicated Plastic Screw Conveyor

A standard conveyor is inadequate for plastic materials. A dedicated Plastic Screw Conveyor is engineered with specific features to handle pellets and regrind:

- Ultra-Smooth Trough Finishes: To combat the issue of plastic adhering to surfaces and to reduce static build-up, our conveyors feature specialized coatings or highly polished stainless steel internals.

- Optimized Fill Ratios: Plastic pellets are typically lighter than mineral powders. The flighting design is often modified to ensure the conveyor operates at the optimal fill ratio (usually between 30-45%) to prevent material degradation (fines generation) caused by excessive churning.

- Abrasion Resistance: While plastics may seem gentle, glass-filled resins and highly abrasive additives can severely reduce the life of standard carbon steel components. Invoit Plast offers specialized alloy construction and flight edge hardening for extended life.

The Role of the Plastic Recycling Conveyor

In the context of the circular economy, the Plastic Recycling Conveyor plays a vital role. Recycling often involves moving irregular, sharp, and high-density materials (shredded plastic, flakes, contaminated waste).

These conveyors are built for maximum durability, featuring:

- Heavy-Duty Construction: Thicker gauge steel troughs and flights to withstand impact and abrasion from non-uniform materials.

- Easy Access Cleanouts: Rapid material changeovers and cleaning are essential in recycling to prevent cross-contamination. Our designs incorporate easily removable lids and large cleanout doors for fast maintenance.

- Integrated Metal Detection/Separation: Often, recycling conveyors must be designed to interface directly with sorting or separation equipment, acting as a crucial element in the contaminant removal process.

By focusing on these industry-specific needs, Invoit Plast ensures your investment in a Plastic Screw Conveyor maximizes throughput and minimizes material loss in even the most challenging environments.

The Invoit Plast Advantage: A Commitment to Manufacturing Excellence

As the Best Invoit Plast Screw Conveyor Manufacturer in India, our commitment extends beyond merely selling machinery. We are partners in your operational success. Our manufacturing philosophy is centered around customization, durability, and support, which is what truly differentiates us in the B2B space.

Customization and Integration

Many suppliers offer off-the-shelf solutions that require costly modification during installation. Invoit Plast operates differently: we custom-engineer every unit to integrate flawlessly with your existing process line.

- Dimensional Accuracy: We match the inlet and outlet dimensions, flange types, and mounting specifications of your existing equipment (mixers, hoppers, silos).

- Material Selection: We offer a range of materials, including SS304, SS316, and specialized wear-resistant alloys, ensuring chemical compatibility and long-term structural integrity.

- Variable Speed Control: Every Screw Conveyor can be fitted with Variable Frequency Drives (VFDs), allowing operators to fine-tune material feed rates precisely, optimizing the performance of downstream machinery and saving power.

Quality and Compliance

Operating out of our state-of-the-art facilities in India, Invoit Plast adheres to stringent international quality standards. We provide full documentation, including Material Test Certificates (MTCs) and comprehensive operational and maintenance manuals. Our dedication to quality control ensures that the conveyor delivered to your site is ready for high-demand, 24/7 industrial use from day one.

Beyond the Sale: Partnering for Long-Term Lead Generation and Support

The purchase of a Screw Conveyor is the beginning of a long-term relationship. What truly turns an initial purchase into a lasting lead and partnership is the after-sales support provided by the Screw Conveyor Manufacturer.

Invoit Plast offers a tiered support structure designed to keep your production line running optimally:

- Proactive Maintenance Guidance: We provide detailed guidance on bearing lubrication, flight wear monitoring, and seal replacement intervals, allowing your team to schedule maintenance proactively and avoid catastrophic, unplanned downtime.

- Rapid Spares Availability: Our dedication to being the Best Invoit Plast Screw Conveyor Manufacturer in India means maintaining a local stock of critical spare parts—including shafts, hanger bearings, and couplings—to ensure that any necessary repairs are completed quickly, minimizing the duration of an outage.

- On-Site Consultation: Our engineering team is available for site visits to consult on challenging material flow applications, troubleshoot existing line issues, and recommend upgrades or modifications to older systems. This partnership approach ensures your investment continues to pay dividends.

Reliability is the Only Metric That Matters

For B2B buyers seeking to drive operational efficiency and secure a rapid return on investment, the choice of a Screw Conveyor Manufacturer must prioritize reliability above all else. A low-cost, unreliable system is the most expensive purchase a company can make.

Invoit Plast Machinery provides the strategic advantage your operation needs—from the versatile Horizontal Screw Conveyor and the dedicated Plastic Screw Conveyor to heavy-duty Plastic Recycling Conveyor solutions. We combine world-class engineering with localized support to deliver material handling systems that simply do not fail.

If you are ready to eliminate bottlenecks, reduce maintenance costs, and ensure guaranteed throughput in your production line, the time to upgrade your handling system is now.

Ready to boost your efficiency and secure your competitive edge?

Contact Invoit Plast Machinery today for a detailed consultation and quote customized for your specific material and throughput requirements.

FAQs

Standard industrial conveyors are often not optimized for plastics. Invoit Plast’s Plastic Screw Conveyor systems are engineered with a specialized flight pitch and gentle handling mechanisms to prevent material fracture, minimize dusting, and ensure consistent, metered flow. This specialization is critical for maintaining raw material integrity and final product quality in plastic processing and recycling operations.

The Horizontal Screw Conveyor is the backbone of plant flexibility. Its primary advantage is providing precise, controlled material distribution over significant distances. It allows for multi-point feeding (supplying several machines from a single source) and accurate batching by metering material out of silos directly into weigh hoppers, ensuring a stable and uniform feed rate to downstream equipment.

We supply heavy-duty Plastic Recycling Conveyor systems specifically designed for irregular, abrasive, and often wet recycled streams like shredded PET or HDPE flakes. These conveyors feature reinforced construction, robust sealing for dust/moisture control, and can include dewatering features to optimize material preparation for subsequent processing stages.

We supply heavy-duty Plastic Recycling Conveyor systems specifically designed for irregular, abrasive, and often wet recycled streams like shredded PET or HDPE flakes. These conveyors feature reinforced construction, robust sealing for dust/moisture control, and can include dewatering features to optimize material preparation for subsequent processing stages.

Reliability is our core promise. As a leading Screw Conveyor Manufacturer, Invoit Plast utilizes premium-grade motors, gearboxes, and bearings. Crucially, every system is custom-engineered and verified to match the specific material bulk density and flow characteristics of your polymer, reducing strain, minimizing hang-up, and guaranteeing maximum operational uptime.

Invoit Plast offers extensive B2B customization. This includes custom angles, lengths, specialized Material of Construction (MOC) like SS304/SS316 for corrosive or food-grade environments, and the integration of Variable Speed Drives (VSDs). This ensures our Screw Conveyor is a seamless, custom-fit asset in your unique plant layout.

Our conveyors eliminate the primary causes of inefficiency: manual labor, spillage, and inconsistent feeding. By providing a continuous, automated, and precisely controlled stream of material directly to your primary processing machinery, the system stabilizes the production process, minimizes downtime, reduces waste, and allows your operators to focus on higher-value tasks like quality control.