Choose the Right Medical Blister Recycling Machine for Your Recycling Plant

In the healthcare industry, medical blister packaging is widely used for tablets, capsules, and various pharmaceutical products. These blister packs are designed for product safety, tamper-resistance, and long shelf life. However, once used, they become a significant source of waste. Recycling these blisters not only reduces environmental pollution but also allows recovery of valuable raw materials like aluminum and plastic.

For a recycling plant, choosing the right medical blister recycling machine is a crucial decision. The right equipment ensures maximum recovery efficiency, high-quality output, and cost-effective operations. This article will guide you through essential points to consider when selecting a machine that meets your operational needs and supports sustainability goals.

Understanding Medical Blister Recycling Machines

A medical blister recycling machine is specialized equipment designed to separate aluminum and plastic layers from used pharmaceutical blister packs. Unlike general recycling machines, these systems are engineered for precision separation without damaging the material quality.

Medical blister waste is often made of PVC (Polyvinyl Chloride) or PET (Polyethylene Terephthalate) combined with a thin aluminum foil layer. The machine’s job is to cleanly separate and process these materials so they can be reused in manufacturing new products.

The demand for these machines is growing rapidly due to strict waste management regulations, the rising cost of raw materials, and the global push toward circular economy practices.

Why the Right Machine Matters

Investing in the right medical blister recycling machine ensures:

- High separation efficiency – Clean separation of aluminum and plastic, minimizing contamination.

- Reduced operational costs – Energy-efficient designs lower electricity consumption.

- Consistent output quality – High-purity recovered materials fetch better resale value.

- Compliance with environmental regulations – Meeting industry and government recycling standards.

Choosing the wrong machine could mean higher maintenance, frequent breakdowns, or poor-quality recycled materials that are harder to sell.

Key Factors to Consider When Choosing a Medical Blister Recycling Machine

When selecting the right recycling machine for your plant, several factors should guide your decision.

- Material Compatibility

Not all blister packs are the same—some use PVC, others PET, and the aluminum layer thickness also varies. Your machine should handle different types of blister materials without frequent adjustments. This flexibility ensures that you can process waste from various sources without downtime.

- Processing Capacity

Capacity is one of the first specifications to check. A high-capacity machine can handle large volumes of blister waste daily, making it ideal for big recycling plants. Smaller plants might opt for medium-capacity machines to avoid overinvestment.

- Separation Technology

Modern blister recycling machines use advanced separation technologies, such as:

- Crushing and granulating systems – Reduce blister size for easier separation.

- Electrostatic separation – Uses static electricity to pull apart aluminum and plastic particles.

- Air separation systems – Blow lighter materials away from heavier ones.

A combination of these systems offers the highest recovery rates.

- Energy Efficiency

Energy costs can eat into your profit margins. Look for machines designed with energy-efficient motors and smart controls that reduce electricity usage without compromising output.

- Ease of Maintenance

Machines with modular designs and easily replaceable components save time and reduce downtime. Check if spare parts are readily available in your region.

- Safety Features

Since you’re dealing with pharmaceutical waste, safety is critical. A good machine should have dust extraction systems, noise control, and enclosed designs to protect operators from exposure.

Benefits of Installing a Medical Blister Recycling Machine in Your Plant

Recycling blister packs not only supports environmental protection but also provides tangible business benefits.

- Revenue from Recovered Materials – High-purity aluminum and plastic can be sold to manufacturers, adding a steady income stream.

- Reduced Waste Disposal Costs – Less material sent to landfills means lower disposal fees.

- Better Sustainability Credentials – Eco-friendly operations attract clients and improve your brand reputation.

- Regulatory Compliance – Avoid fines and penalties by meeting recycling mandates.

The Role of Automation in Modern Blister Recycling Machines

Automation is transforming the recycling industry. Today’s medical blister recycling machines come with PLC-based control panels, touch-screen interfaces, and automatic feeding systems. This automation ensures consistent operation, minimal manual intervention, and reduced labor costs.

Smart automation also allows for real-time monitoring of separation efficiency, energy use, and maintenance schedules, helping you optimize performance.

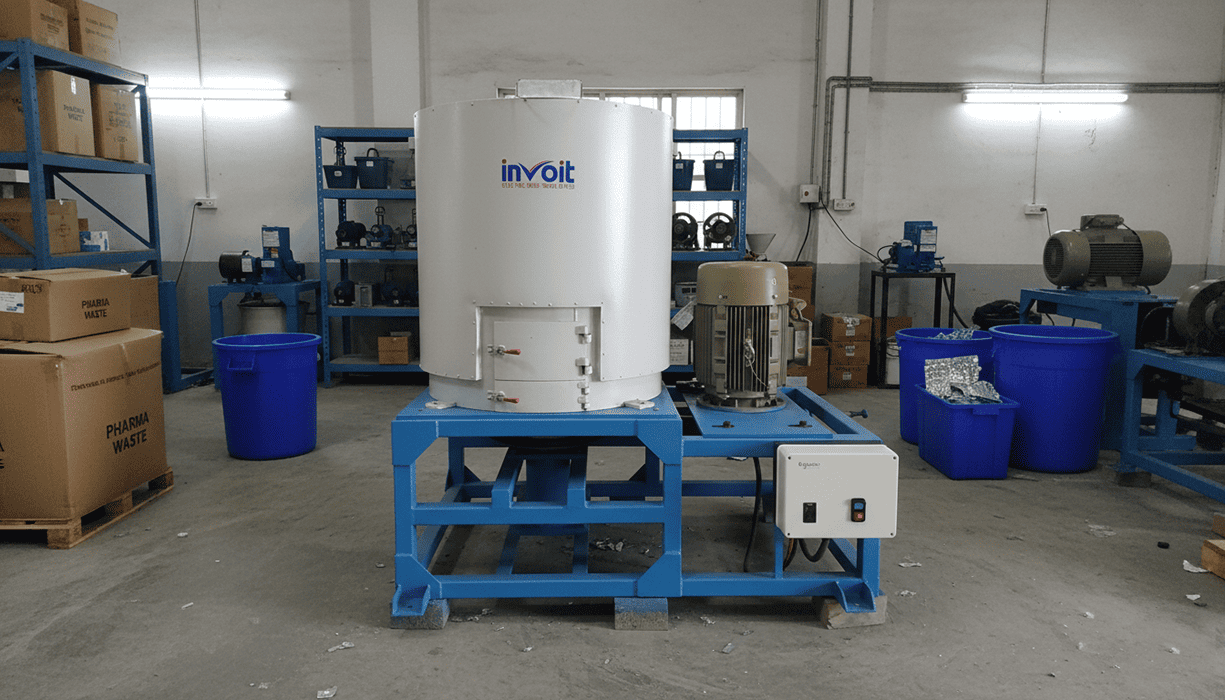

How Invoit Plast Machinery PVT Ltd Delivers the Best Medical Blister Recycling Solutions

When it comes to finding the best medical blister recycling machine manufacturer in India, Invoit Plast Machinery Pvt. Ltd. stands out. With years of expertise in designing and manufacturing advanced recycling machines, Invoit Plast offers equipment that combines durability, precision, and high efficiency.

Their machines are built with:

- Robust construction for long operational life.

- Advanced separation technology for maximum recovery of aluminum and plastic.

- Energy-efficient designs that reduce operational costs.

- Customizable models to suit different plant sizes and recycling capacities.

By partnering with Invoit Plast, you’re not just buying a machine—you’re investing in reliable performance, ongoing support, and a solution tailored to your plant’s needs.

Future Trends in Medical Blister Recycling Technology

The recycling industry is evolving quickly, and medical blister recycling is no exception. Some trends to watch include:

- AI-driven Sorting – Artificial intelligence to identify and separate different blister types.

- Low-Temperature Processing – Methods that reduce energy usage while protecting material integrity.

- Compact Designs – Space-saving machines for smaller recycling units.

- Eco-Friendly Manufacturing – Machines built with recyclable parts and sustainable manufacturing processes.

By investing in the latest technology now, your plant can stay ahead of competitors and meet future recycling demands.

Final Thoughts

Choosing the right medical blister recycling machine is an investment that can define the efficiency and profitability of your recycling plant for years to come. Factors like material compatibility, processing capacity, separation technology, energy efficiency, and safety features should all play a role in your decision-making process.

If you’re looking for a reliable, high-performance solution, Invoit Plast Machinery Pvt. Ltd. offers some of the most advanced medical blister recycling machines in India. With their expertise, commitment to quality, and customer-focused approach, you can be confident you’re making the right choice for both your business and the environment.

A well-chosen machine will not only help you meet recycling targets but also turn pharmaceutical waste into valuable resources—creating a win-win for your plant and the planet.

FAQs

A medical blister recycling machine is specialized equipment designed to separate and recover aluminum and plastic from pharmaceutical blister packaging. These machines ensure clean separation, enabling both materials to be reused in new manufacturing processes.

Recycling medical blister packs reduces environmental waste, recovers valuable raw materials, and ensures compliance with waste management regulations. It also helps recycling plants generate revenue from selling the recovered aluminum and plastic.

The machine typically crushes the blister packs into small pieces, then uses a combination of electrostatic, air, and mechanical separation methods to separate the aluminum and plastic layers with high precision.

Advanced machines, like those from Invoit Plast Machinery Pvt. Ltd., are designed to handle a variety of blister types, including PVC, PET, and composite aluminum-plastic packs, without frequent manual adjustments.

The capacity depends on your plant’s daily processing needs. Large-scale plants require high-capacity machines, while smaller plants can benefit from medium-capacity models to avoid unnecessary costs.

Energy-efficient machines lower electricity costs, reduce environmental impact, and offer a better return on investment by maintaining high recovery rates without excessive power consumption.

Yes, quality machines come with dust extraction systems, enclosed designs, and noise control measures to ensure safe and comfortable operation for workers.

Invoit Plast Machinery Pvt. Ltd. is recognized as one of the best medical blister recycling machine manufacturers in India, offering durable, efficient, and customizable machines for different recycling plant needs.

Invoit Plast Machinery Pvt. Ltd. is recognized as one of the best medical blister recycling machine manufacturers in India, offering durable, efficient, and customizable machines for different recycling plant needs.

The future includes AI-powered sorting systems, low-temperature processing for better material quality, compact designs for space-saving, and eco-friendly manufacturing methods for sustainable recycling operations.