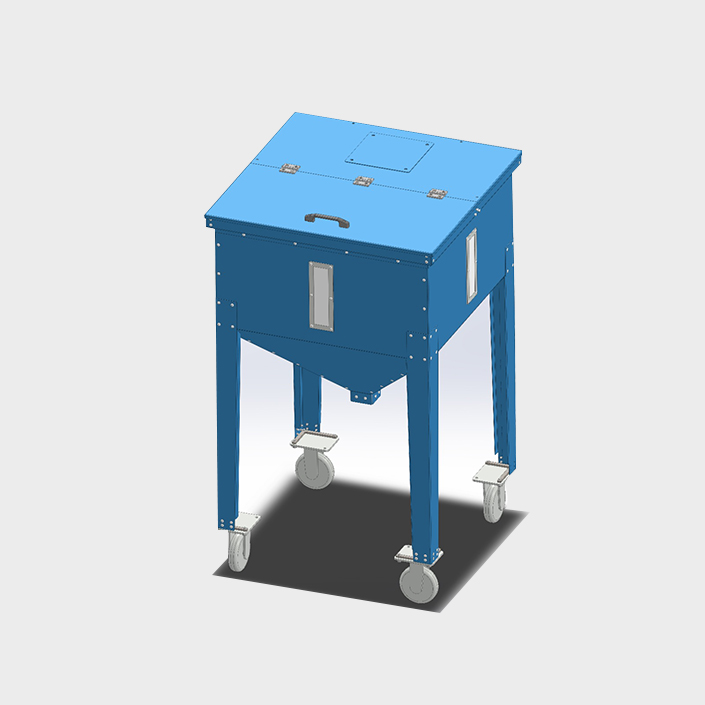

Debagging Bin

Debagging Bin

At Invoit Plast Machinery Pvt. Ltd., we understand that efficient material handling is key to ensuring smooth and productive operations across various industries, including manufacturing, packaging, and plastics. One of the essential tools for optimizing the workflow in these industries is the debagg¬ing bin. A debagging bin is designed to remove packaging materials such as plastic bags, films, or sacks from raw materials, products, or waste, enhancing both operational efficiency and safety.

What is a Debagging Bin?

A debagging bin is a specialized machine that helps remove unwanted packaging materials, typically plastic bags or film, from products, ensuring a smooth flow of materials through the production process. Whether in manufacturing, packaging, or plastics industries, the ability to quickly and efficiently remove these materials is crucial for maintaining a clean and uninterrupted workflow.

Functions of Debagging Bins

- Improved Workflow: By removing packaging materials automatically and quickly, debagging bins ensure that materials flow seamlessly through the production line. This helps eliminate bottlenecks and downtime caused by manual removal, keeping production processes on track.

- Enhanced Safety: Manually removing packaging materials can be hazardous, particularly when workers are exposed to sharp objects or are required to handle large quantities of packaging. Debagging bins automate this task, reducing the risk of accidents, injuries, and repetitive strain injuries (RSI).

- Reduced Labor Costs: Automating the debagging process significantly reduces the need for manual labor, leading to substantial savings in labor costs. With fewer workers required for this task, resources can be allocated to other areas of the production process, increasing overall productivity.

- Environmental Advantages: Efficient debagging leads to better handling and sorting of packaging materials, ensuring that waste is properly disposed of or recycled. This contributes to a reduction in environmental impact, aligning with sustainable practices and corporate responsibility goals.

Types and Sizes of Debagging Bins

Debagging bins come in a variety of types and sizes to suit different production environments and requirements:

- Standard Debagging Bins: These are typically used in industries with moderate production volumes. They are designed to handle a wide range of packaging materials, including plastic bags, films, and other flexible packaging.

- Heavy-Duty Debagging Bins: For industries with high-volume production, heavy-duty debagging bins are required. These models are built to handle larger loads and tougher materials, ensuring efficient removal of packaging in demanding environments.

- Compact Debagging Bins: For facilities with limited space, compact debagging bins are ideal. They offer all the features of larger models but are designed to take up less room while maintaining efficiency in bag removal.

- Customizable Bins: Invoit Plast offers customizable debagging bins tailored to specific industry needs. From varying bin sizes to specialized features like automated conveyors or sensors for detecting bags, we ensure the debagging bin meets your exact requirements.

Technological Advancements in Debagging Bin Designs

As industries evolve and production processes become more complex, the technology behind debagging bins has also advanced. At Invoit Plast, we utilize the latest innovations to offer our customers the most efficient and streamlined solutions.

- Automation and Sensors: Modern debagging bins are equipped with automation systems, such as conveyor belts and sensors that detect packaging materials and ensure efficient removal. These systems help minimize human intervention and increase accuracy and speed.

- Smart Waste Collection Systems: Newer designs incorporate smart waste management features that allow for real-time monitoring of packaging waste, providing data on collection rates and waste volumes. This enables more effective management and disposal, contributing to sustainability goals.

- Ergonomic Design: Advanced debagging bins are ergonomically designed to reduce strain on workers and improve the ease of material handling. Features like height-adjustable bins or easy-to-access waste compartments ensure a safer and more comfortable working environment.

- Energy-Efficient Models: The latest debagging bins are designed with energy efficiency in mind, utilizing low-energy motors and eco-friendly materials. These machines not only reduce operational costs but also contribute to greener, more sustainable production practices.

Invoit Plast Machinery Pvt. Ltd. provides a range of high-quality debagging bins designed to meet the needs of various industries such as manufacturing, packaging, and plastics. Our debagging bins offer numerous benefits, from improved workflow and safety to reduced labor costs and environmental impact. With the latest technological advancements in automation and smart waste management, our debagging bins are designed to streamline and optimize your production processes, ensuring maximum efficiency.

When selecting a debagging bin for your business, consider the type of materials you process, the volume of production, and the space available in your facility. Invoit Plast offers a comprehensive range of debagging bins in various sizes, from compact models to heavy-duty systems, all engineered for high-performance operation.