How the Plastic Granulator Machine Improves Scrap Management in Industrial Production Lines

In today’s hyper-competitive manufacturing landscape, the true measure of efficiency lies not just in output volume, but in the intelligent management of resources—especially waste. For any industry relying on thermoplastic materials, from injection molding to film extrusion, the generation of scrap, sprues, rejects, and off-cuts is inevitable. Handling this bulky, often inconsistent material stream traditionally incurs significant costs and logistical headaches. This is precisely where the modern Plastic Granulator Machine transcends its simple mechanical function, evolving into a strategic asset for operational resilience and economic sustainability. It is the core technology that converts waste liabilities into immediately reusable raw material assets, fundamentally restructuring industrial scrap management.

The Cost of Inefficiency: Why Conventional Scrap Handling Fails

The traditional linear production model—buy virgin material, process, sell products, and dispose of waste—is fundamentally flawed for the plastics sector. Storing large, irregularly shaped plastic scrap, whether thick-walled rejects or lightweight film remnants, consumes valuable floor space, creating potential safety hazards and operational bottlenecks. Hauling this bulky waste offsite involves frequent transportation, adding substantial disposal fees and logistics overheads. More importantly, every kilogram of scrap sent to a landfill or external recycler represents lost material value that the company has already paid for, drastically impacting the overall material costs and profit margins.

Precision and Performance: The Core Function of the Plastic Granulator

The Plastic Granulator is not merely a grinder; it is a high-precision size-reduction engine engineered to transform heterogeneous scrap into a homogeneous, uniform output known as regrind or granules. This transformation is achieved through a carefully designed cutting chamber where rotating blades work in tandem with stationary blades, cleanly slicing the plastic material against a sizing screen. This process results in consistent particle size, which is critical for successful reintegration into the production process.

Modern granulators are specialized to handle various polymers—from rigid engineering plastics like ABS and polycarbonate to flexible materials like LDPE and PP films. Factors such as rotor configuration (open, closed, or staggered), cutting geometry, and motor power are customized to ensure optimal cutting action, minimal friction, and reduced heat generation. This mechanical expertise ensures the thermal integrity of the polymer is maintained, guaranteeing that the regrind retains the quality necessary for producing non-defective, new products. Investing in a high-quality Plastic Granulator minimizes contamination risk and ensures consistent material flow, which is paramount for high-tolerance manufacturing.

Economic and Environmental Superiority Through Closed-Loop Recycling

Implementing an in-house granulator system immediately activates a closed-loop recycling infrastructure, delivering profound economic and environmental benefits.

Maximizing Resource Utilization

The primary financial advantage is the drastic reduction in the reliance on expensive virgin raw materials. By granulating internal production scrap—like runners, sprues, and defective parts—and feeding it directly back into the extruder or injection molding machine, manufacturers instantly monetize their waste stream. This internal material recovery drastically lowers the total material acquisition cost. Furthermore, a consistent supply of regrind means production downtime caused by waiting for external material shipments is minimized, enhancing overall production continuity. This strategy turns a non-performing asset (scrap) into a cost-saving input.

Streamlined Logistics and Reduced Cost of Waste

The density of plastic changes dramatically after granulation. Where bulky, inconsistent waste requires large bins and frequent, costly collections, the granulated material is compact, uniform, and easily stored in silos or manageable containers. This immediate size reduction translates directly to reduced waste disposal fees and less frequent hauls, leading to significant savings in logistics and operational labor.

The Sustainability Mandate

In today’s corporate environment, sustainability is not a choice, but a mandate. Utilizing a Plastic Recycling Machine within the plant demonstrates a clear commitment to circular economy principles. This commitment not only aligns the company with global environmental compliance standards but also strengthens brand reputation. Customers and B2B partners increasingly prioritize suppliers who can prove minimized environmental impact, making in-house recycling a vital competitive differentiator.

Operational Advantage: Integration, Safety, and Longevity

Integrating the Plastic Granulator Machine effectively requires careful consideration of its placement, typically either beside-the-press (for immediate regrinding of small scrap) or in a centralized location (for high-volume processing).

Automation and Efficiency

The design of modern granulators prioritizes seamless integration into automated production lines. Features like automated feeding systems, metal detection, and integrated dust extraction systems ensure continuous, maintenance-light operation. Slow-speed granulators, for example, are increasingly popular for beside-the-press applications due to their quiet operation, minimal dust generation, and reduced energy consumption, making them perfect for clean room or high-precision environments. These efficiencies contribute to better Plastic Granulator Machine performance metrics across the entire facility.

The Importance of Engineering Excellence and Support

When making an investment of this magnitude, the reliability of the Manufacturer is paramount. A machine must be robust, energy-efficient, and backed by comprehensive service. This brings us to a crucial point of differentiation in the market: the quality of the machinery and the support network behind it. It is essential to partner with companies known for precision engineering, rigorous testing, and dedication to longevity.

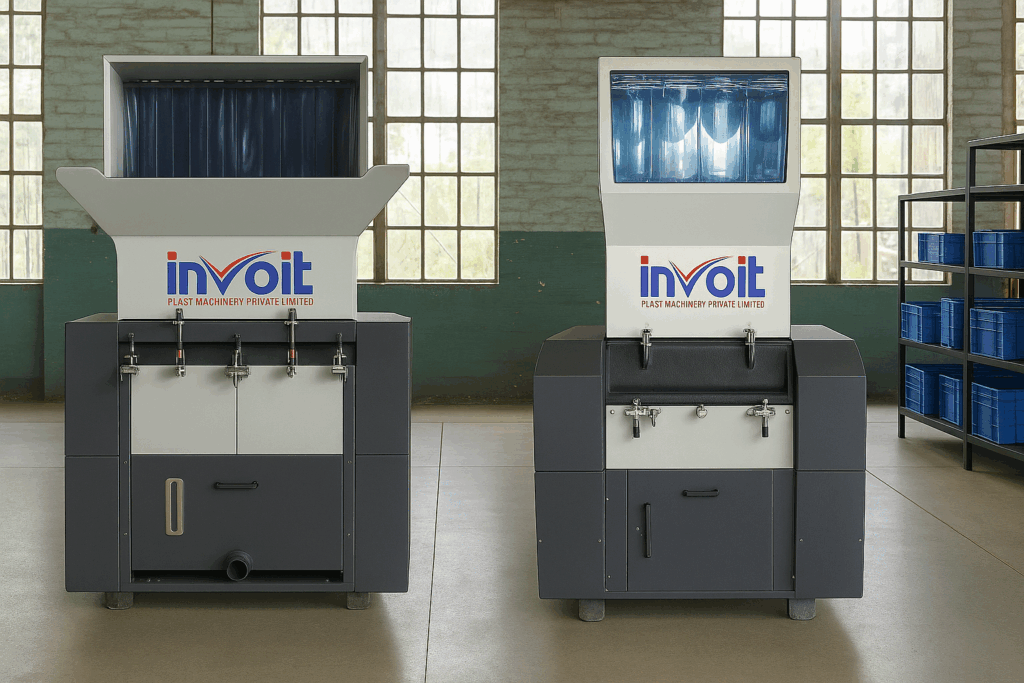

In this regard, we recognize the reputation for quality and engineering precision established by Invoitplast Machinery Best Plastic Granulator Machine Manufacturer in India. Their focus on robust design, high-performance rotors, and application-specific configurations ensures the durability and consistent performance required for demanding industrial environments. Choosing a trusted partner ensures not only machine quality but also prompt, expert technical support, minimizing potential downtime and maximizing the return on investment.

The Granule-to-Product Cycle

Once the scrap has been processed by the Plastic Granulator, the resulting granules are typically conveyed back into a storage system or directly mixed with virgin material via a dosing unit. The uniform size of the granules is key, as it ensures consistent melt flow and prevents blockages or variations in the final product density. This precise control over regrind quality is what allows manufacturers to safely maintain high regrind inclusion ratios without compromising the mechanical or aesthetic properties of the finished item. Whether the material is being used in an extrusion process to create new pipe or in an injection molding unit to form a complex automotive part, the Plastic Recycling Machine guarantees that material value is preserved and recaptured in a continuous, high-yield cycle.

Turning Waste into a Wealth of Opportunity

The adoption of a high-performance Plastic Granulator is more than an equipment upgrade; it is a transition to a fundamentally smarter, more profitable, and environmentally responsible manufacturing model. By effectively managing internal scrap, minimizing external disposal costs, and recapturing the value embedded in plastic waste, industries secure a competitive edge and build resilience against fluctuating raw material markets. This machine is the indispensable link that closes the recycling loop, transforming production line byproducts into a consistent, valuable input. For manufacturers looking to enhance efficiency, meet sustainability targets, and maximize resource utilization, the intelligent application of the modern Plastic Granulator Machine is the definitive path forward.

FAQs

A Plastic Granulator Machine is a size-reduction system designed to convert bulky plastic scrap—such as sprues, runners, off-cuts, and rejected parts—into uniform regrind. It is essential because it helps manufacturers recover material value, reduce waste handling costs, and maintain a continuous internal recycling loop, improving overall production efficiency.

The machine reduces large, irregular scrap into consistent granules that can be reused immediately in production. This eliminates waste storage issues, reduces logistics expenses, and allows companies to reintegrate regrind directly into their injection molding or extrusion processes.

A Plastic Granulator Machine can process a wide range of polymers, including ABS, PC, PP, PE, PET, PVC, HDPE, LDPE, nylon, and flexible films. Modern granulators are engineered to handle soft, rigid, thick-walled, and even engineering-grade plastics with precision.

Yes. High-quality granulators produce uniform particle sizes, ensuring consistent melt flow and stable processing parameters. This makes the regrind suitable for reinjection or re-extrusion, often allowing manufacturers to achieve high regrind ratios without affecting product quality.

By recycling internal scrap in-house, manufacturers reduce their dependency on costly virgin raw materials. Granulation also decreases waste disposal costs, lowers transportation needs, and minimizes inventory of scrap, resulting in substantial long-term savings.

A Plastic Recycling Machine like a granulator helps companies adopt a closed-loop recycling model. By converting waste into reusable material, industries reduce their carbon footprint, comply with environmental regulations, and demonstrate commitment to circular economy practices.

Key features include:

- Precision-engineered rotors

- Strong cutting chamber

- Consistent output size

- Low heat generation

- Energy-efficient motors

- Noise and dust control

- Easy maintenance and robust build

These ensure long-term performance, reliability, and safe operation.

- Slow-speed granulators are ideal beside-the-press for regrinding small sprues and runners with minimal noise and dust.

- Heavy-duty granulators are built for centralized systems and handle high-volume, thick, or tough materials.

The choice depends on scrap type, production volume, and workflow.

Automated feeding systems, metal detectors, and dust extraction units help maintain consistent throughput, reduce operator intervention, minimize contamination, and ensure smooth integration with automated production lines.

A reputed manufacturer ensures durable design, precision engineering, and reliable performance. Brands like Invoitplast Machinery — one of the Best Plastic Granulator Machine Manufacturers in India — offer high-quality components, application-specific configurations, and strong technical support, ensuring maximum machine uptime and ROI.

Regular maintenance includes:

- Sharpening/changing blades

- Cleaning screens

- Checking bearings and belts

- Lubrication

- Removing dust buildup

Routine upkeep prevents downtime and ensures consistent cutting performance.

Yes. By converting bulky scrap into compact granules, storage requirements drastically decrease. Uniform regrind can be stored in bags, silos, or bins, freeing up valuable floor space and reducing clutter.

When processed using a high-performance granulator, the regrind maintains thermal and mechanical integrity. As long as contamination is controlled, manufacturers can use it to produce stable, defect-free components.

Absolutely. In-house recycling supports compliance with sustainability standards, EPR (Extended Producer Responsibility), ISO environmental certifications, and global circular economy initiatives. It also enhances brand credibility with OEMs and buyers.

- Beside-the-press granulators are ideal for immediate scrap recycling and faster material return.

- Centralized granulators are better for handling large volumes from multiple machines.

The choice depends on production size, scrap type, and factory workflow.