How Plastic Scrap Grinder Machine Helps in Reducing Waste Volume

Plastic waste management has become one of the most pressing concerns of modern manufacturing and industrial processes. With rising awareness about sustainability and environmental preservation, industries are shifting their focus towards efficient waste handling systems. One of the most effective solutions for reducing the volume of plastic waste is the Plastic Scrap Grinder Machine.

A Plastic Scrap Grinder Machine, also known as a Plastic waste grinder, plays a crucial role in the recycling and reprocessing of plastic materials. This machine grinds various forms of plastic scrap into fine granules or flakes, making them easier to store, transport, and reuse in production.

Let’s explore in detail how this machine contributes significantly to waste reduction in the plastic industry.

The Problem of Plastic Waste Volume

Plastic is durable, lightweight, and versatile, but these same qualities also make it a major environmental pollutant. Industrial and post-consumer plastic waste such as containers, sheets, pipes, automotive parts, and packaging materials can accumulate rapidly if not managed properly. This leads to:

- Large storage requirements

- Difficult handling and transportation

- Increased risk of environmental pollution

- Loss of reusable plastic material

The solution lies in reducing the volume of plastic waste without compromising its recyclability. That’s where the Plastic Scrap Grinder Machine comes into play.

What is a Plastic Scrap Grinder Machine?

A Plastic Scrap Grinder Machine is a mechanical device designed to break down bulky plastic products into smaller pieces. These machines can handle various materials like HDPE grinding scrap, PET bottles, PVC pipes, PP items, and other forms of thermoplastics.

The machine consists of hardened steel blades, a high-torque motor, and a sturdy grinding chamber. Once the plastic scrap is loaded into the machine, it is shredded or crushed into fine particles that can be reprocessed in extrusion or molding machines.

How It Helps in Reducing Waste Volume

Converts Bulky Plastics into Manageable Granules

One of the biggest advantages of using a plastic waste grinder is its ability to reduce large plastic items into small, uniform granules. These granules occupy far less space than unprocessed plastic waste. As a result, companies can:

- Optimize warehouse space

- Reduce waste handling costs

- Lower transportation expenses

This directly contributes to reduced volume of plastic waste in storage facilities, landfills, or recycling units.

Enables Efficient Recycling of HDPE Grinding Scrap

HDPE (High-Density Polyethylene) is widely used in the manufacture of bottles, drums, and industrial containers. These items are often thick-walled and voluminous. When discarded, HDPE grinding scrap consumes a significant amount of space.

A Plastic Scrap Grinder Machine processes these HDPE items into flakes or powder, making them suitable for re-introduction into the production cycle. This not only reduces waste volume but also encourages material recovery and circular economy practices.

Reduces the Need for Frequent Waste Disposal

By reducing the size of plastic waste, businesses can store more material in a smaller area and dispose of it less frequently. This leads to:

- Lower disposal frequency

- Reduced labor and transport needs

- Cost savings in waste management

For industries with high-volume plastic production or consumption, this is a major benefit in maintaining cleaner, more organized workspaces.

Supports Eco-Friendly Manufacturing

With growing environmental regulations, many companies are adopting green manufacturing practices. Using a Plastic waste grinder is an eco-conscious step because:

- It supports internal recycling

- Reduces the dependency on virgin plastic

- Minimizes environmental footprint

Grinding and reusing plastic waste internally significantly reduces the volume of waste going to landfills or incineration, thereby promoting sustainable manufacturing.

Improves Material Handling and Logistics

Handling large plastic items is challenging in terms of manual labor, equipment needs, and safety. Crushed or ground plastic is easier to handle, bag, label, and move.

- Reduces the need for large pallets or crates

- Enhances packing efficiency

- Simplifies inventory tracking

Better logistics contribute to reduced operational costs and higher efficiency in waste processing workflows.

Enhances Cleanliness and Safety in Production Units

Unmanaged plastic waste can clutter manufacturing areas and pose safety risks such as tripping, fire hazards, and machinery obstruction. By grinding the waste immediately, companies maintain cleaner floors and safer working conditions.

- Prevents plastic pile-up

- Reduces pest and contamination risks

- Supports compliance with industrial safety standards

This process plays a vital role in maintaining hygiene and discipline in the workplace.

Facilitates Faster Sorting and Categorization

Ground plastic can be easily sorted by type, color, or quality, which is more difficult when dealing with large plastic parts. This sorting is essential for efficient recycling and quality control in reprocessing plants.

A Plastic Scrap Grinder Machine simplifies segregation and batch management, especially in multi-type plastic recycling units.

Applications Across Industries

Plastic waste grinders are used across multiple sectors where plastic use and waste generation are common. Some key industries include:

- Plastic packaging and film industries

- Injection molding and blow molding units

- Automotive and electrical parts manufacturers

- Plastic furniture and consumer goods

- Pipe and conduit manufacturers (especially for HDPE grinding scrap)

These industries rely on grinding machines to reduce the size of waste and maintain streamlined production and recycling cycles.

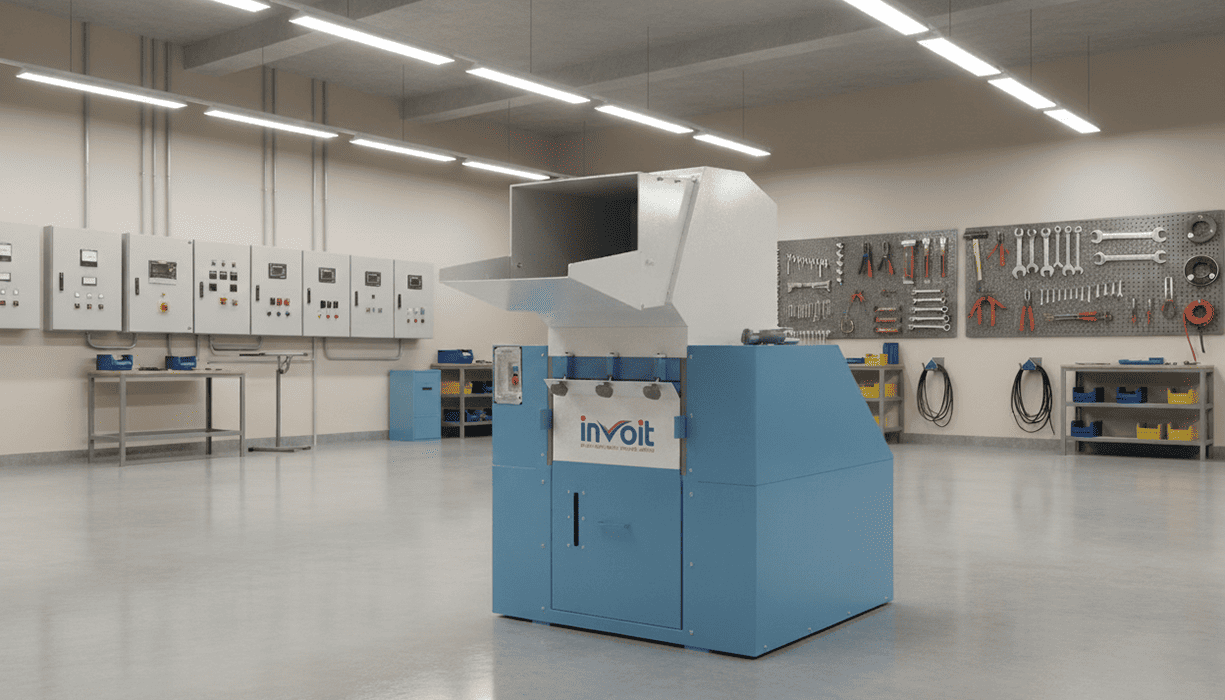

Why Choose Invoit Plast Machinery Pvt Ltd?

When it comes to high-performance Plastic Scrap Grinder Machines, Invoit Plast Machinery Pvt Ltd stands out as the best manufacturer in India. With years of experience, precision engineering, and robust designs, Invoit Plast offers grinders that:

- Deliver superior grinding efficiency

- Are compatible with a wide range of plastic types

- Feature low power consumption and high throughput

- Come with sturdy construction and easy maintenance

Whether your business deals with Plastic waste grinder applications or needs a heavy-duty solution for HDPE grinding scrap, Invoit Plast offers customized machines tailored to industrial requirements.

Final Thoughts

Reducing the volume of plastic waste is a critical step toward achieving efficient recycling and sustainable manufacturing. A Plastic Scrap Grinder Machine plays a pivotal role in converting bulky, unusable plastic into manageable, reusable material. Its benefits extend beyond waste volume reduction to cost efficiency, safety, cleanliness, and eco-friendliness.

Businesses across sectors can optimize space, reduce disposal frequency, and contribute to a circular economy by integrating these machines into their production line. And for those looking for the best-in-class grinding solutions, Invoit Plast Machinery Pvt Ltd provides unmatched reliability and quality as India’s trusted manufacturer.

Investing in a Plastic Scrap Grinder Machine is not just about reducing waste—it’s about transforming how industries view and handle plastic for a better, greener future.

FAQs

A Plastic Scrap Grinder Machine grinds plastic waste into small flakes or granules, reducing its volume for easier handling and recycling.

Yes, most industrial grinders can handle HDPE grinding scrap like drums, bottles, and containers efficiently.

By minimizing the waste size, it reduces the frequency of disposal and storage needs, thereby cutting down on logistics and labor costs.

Yes, grinders are available in various capacities suitable for small to large-scale operations.

Invoit Plast is renowned for manufacturing robust, efficient, and customizable Plastic waste grinder machines, making them a top choice in India.