Plastic Mixer Machine Explained: Types, Uses & Advantages

Selecting the right plastic mixer machine is one of the most crucial decisions for businesses in the plastic manufacturing industry. Whether you are producing PVC pipes, plastic sheets, or granules, efficient mixing directly impacts product quality and operational costs. A well-chosen mixer ensures uniform material blending, better color distribution, and smooth processing in extrusion or molding.

With various options like plastic granules mixer machine, High-Speed Mixer Machine, and Vertical Batch Mixer, understanding your exact requirements is key to making the right investment. In this guide, we’ll walk you through the important factors to consider when buying a plastic mixer machine and how to choose a reliable manufacturer for long-term benefits.

Understanding Plastic Mixer Machines and Their Role

A plastic mixer machine is designed to mix raw materials, additives, and colorants into a homogeneous blend before further processing. The mixing stage determines the final product’s strength, color consistency, and finish quality. If your mixing process is inefficient, you might face production delays, uneven color, or poor-quality products.

Different mixers like plastic dana mixer machine, Storage Mixer Machine, and High-Speed Mixer for plastic cater to specific needs. For example:

- High-Speed Mixer Machine: Ideal for PVC and other heat-sensitive materials, ensuring quick and efficient blending.

- Vertical Batch Mixer Machine: Best for large-volume batch processing.

- Budget Mixer Machine: Suitable for small-scale operations looking for cost-effective solutions.

When choosing the right machine, focus on capacity, material compatibility, and ease of maintenance.

Key Factors to Consider When Choosing a Plastic Mixer Machine

Type of Material and Application

Your material type decides which mixer is best for your business. For example, PVC mixer machines require high-speed mixing due to heat sensitivity, while general plastic granule mixer models are suitable for uniform blending of granules and masterbatches.

If you deal with multiple raw materials, opt for a high-speed mixer for plastic that ensures quick, uniform mixing without degrading the material quality.

Capacity and Production Scale

Choosing the correct capacity prevents production delays and avoids unnecessary energy costs. Small businesses can opt for a Budget Mixer Machine, while large-scale manufacturers benefit from Vertical Batch Mixer Machine models that handle large volumes efficiently.

Machine Speed and Efficiency

A High-Speed Mixer Machine significantly reduces mixing time, improves batch consistency, and supports continuous production. If your business involves high-volume processing of PVC or similar compounds, investing in a High-Speed Mixer Machine Manufacturer with proven performance is essential.

Build Quality and Durability

Mixers must withstand continuous operation and abrasive materials. Look for features like robust stainless-steel construction, precision blades, and strong seals to ensure long-lasting performance.

Energy Efficiency and Maintenance

Energy efficiency is vital to reducing operational costs. Advanced mixers come with optimized motor systems and easy-to-clean designs, which minimize downtime and reduce maintenance expenses.

Safety and Automation Features

Modern mixers include safety interlocks, temperature sensors, and automated controls to prevent accidents and ensure consistent mixing. If you want precise and repeatable results, choose a mixer with digital control systems.

Types of Plastic Mixer Machines in the Market

High-Speed Mixer Machine

The High-Speed Mixer Machine is the most popular for PVC compounding and color mixing. It quickly heats and blends materials, reducing processing time. It’s perfect for businesses demanding high productivity and precision.

Vertical Batch Mixer Machine

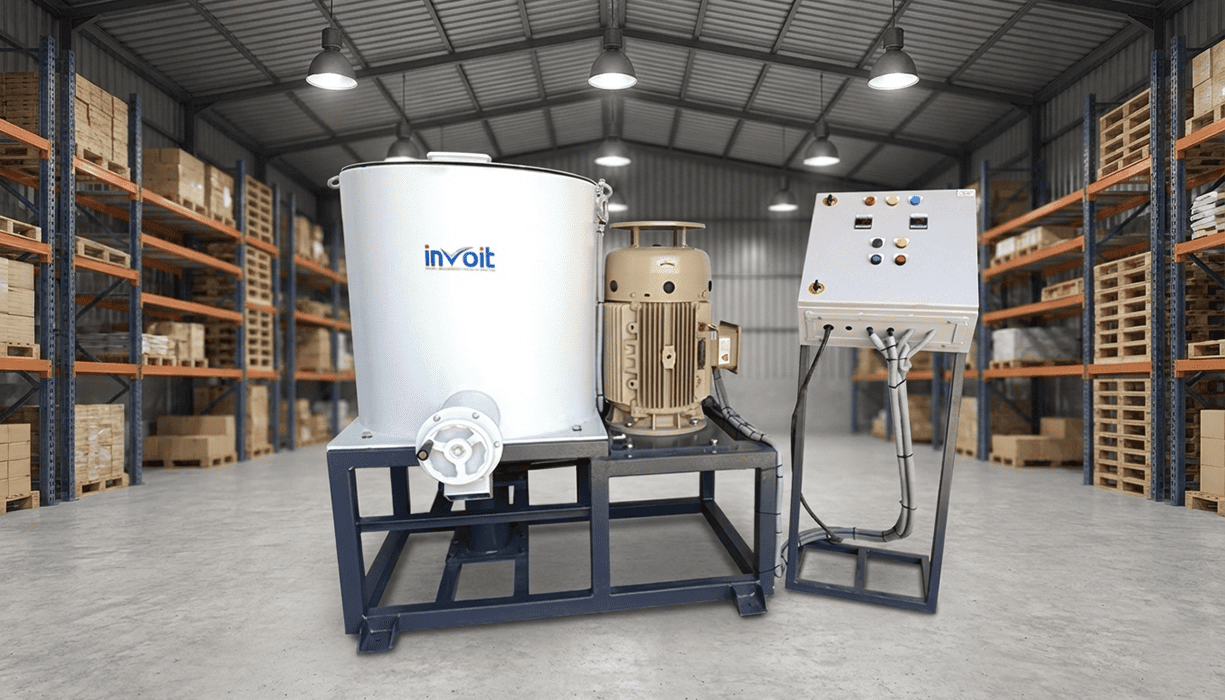

As a leading Vertical Batch Mixer Machine Manufacturer, Invoitplast offers mixers ideal for bulk material handling and storage integration. They provide consistent mixing for large volumes while saving space.

Storage Mixer Machine

Storage Mixer Machines combine storage and mixing functions, helping industries streamline material handling. They are essential for plants where space optimization is a priority.

Budget Mixer Machine

Designed for startups and small-scale manufacturers, Budget Mixer Machines offer efficient mixing at a lower investment. They maintain consistent quality without compromising reliability.

Why Choosing the Right Manufacturer Matters

A high-quality machine from a trusted plastic granules mixer manufacturer in India ensures reliability, durability, and after-sales support. Partnering with the wrong supplier can lead to frequent breakdowns, poor mixing results, and high maintenance costs.

Invoitplast Machinery Pvt. Ltd. stands out as the best Plastic Mixer Machine Manufacturer in Ahmedabad, India, offering a wide range of solutions including plastic granules mixer machines, PVC mixer machines, and high-speed mixers for plastic. With advanced technology, superior build quality, and excellent service, Invoitplast ensures you get the best return on your investment.

Practical Tips Before Making the Purchase

- Assess Your Production Needs: Determine capacity and speed requirements before finalizing the model.

- Check Mixer Versatility: If you process multiple materials, choose a machine adaptable to different applications.

- Compare Granules Mixer Machine Price: While cost matters, prioritize durability and performance over cheap alternatives.

- Inspect Quality Certifications: Ensure the manufacturer follows strict quality standards and offers warranty support.

- Ask About After-Sales Service: Quick service and readily available spare parts reduce downtime and losses.

Final Thoughts

Investing in the right plastic mixer machine boosts production efficiency, improves product quality, and lowers operational costs. From plastic granules mixer machines and PVC mixer machines to High-Speed Mixer Machines, each model serves a specific purpose. By evaluating your material type, capacity, and operational needs, you can select the best option for your business.

If you are looking for a trusted partner, Invoitplast Machinery Pvt. Ltd. is the go-to plastic granules mixer manufacturer in India, delivering high-performance machines with exceptional durability and service. Make the right choice today to secure long-term productivity and success for your business.

FAQs

A plastic mixer machine is used to mix raw materials, additives, and colorants for plastic manufacturing. It ensures uniform blending, improves color consistency, and enhances product quality before processing.

For PVC, a High-Speed Mixer Machine is ideal because it handles heat-sensitive compounds efficiently and reduces mixing time while maintaining quality.

Consider your production capacity, type of material, energy efficiency, and ease of maintenance when selecting a plastic granules mixer machine. Always opt for a reliable plastic granules mixer manufacturer in India for long-lasting performance.

The plastic mixer machine price varies depending on capacity, speed, and features like automation. While exact prices differ, focus on quality and after-sales support rather than just cost.

A High-Speed Mixer Machine is designed for fast blending and heating of materials like PVC, while a Storage Mixer Machine combines mixing and storage, ideal for optimizing space and streamlining processes.

A Vertical Batch Mixer Machine is perfect for large-scale operations requiring uniform mixing in high-volume batches. It saves floor space and integrates easily with material handling systems.

Yes, a Budget Mixer Machine is an excellent choice for small-scale businesses. It offers efficient mixing at a lower investment without compromising on quality.

Invoitplast Machinery Pvt. Ltd. is one of the best Plastic Mixer Machine Manufacturers in Ahmedabad, India, offering advanced solutions like plastic granules mixer machines, PVC mixer machines, and high-speed mixers for plastic with excellent after-sales service.