How to Select the Right Vibro Screen for Your Industry – Working Principle & Buyer's Guide

When it comes to precision screening and separation processes, a gyro screen machine is one of the most reliable solutions for industries across India. Whether you belong to plastics, chemicals, pharmaceuticals, food processing, or minerals, investing in the right gyro screen manufacturer ensures you get high performance, durability, and value for money. But with multiple options available, how do you select the best Gyro Screen Manufacturer in India for your business?

In this detailed guide, we’ll walk you through everything you need to know about choosing the right partner for gyroscreens and screening equipment in India, while also introducing you to a trusted name in the industry — Invoit Plast Machinery Pvt. Ltd., a leading manufacturer delivering top-quality screening solutions.

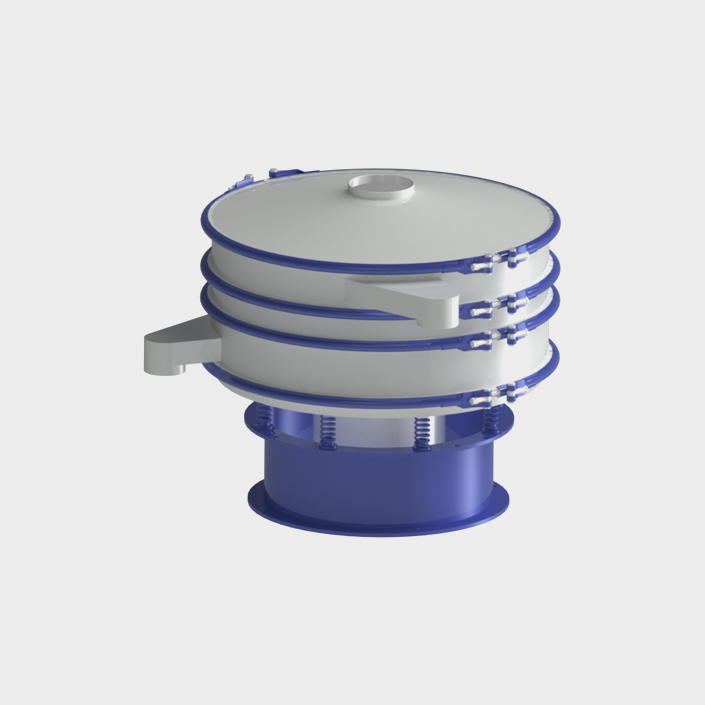

What is a Gyro Screen Machine?

A gyro screen machine, also known as a vibro sifter or gyroscreen, is a type of screening equipment used to separate materials based on particle size. It works on the principle of gyratory motion, which enables precise screening, grading, and filtration.

Key Benefits of Gyro Screen Machines:

- High efficiency in screening, grading, and filtering.

- Versatility to handle powders, granules, and liquids.

- Compact design with easy installation.

- Low maintenance and long operational life.

- Customizable screens for different applications.

From plastics and polymers to food grains, chemicals, and minerals, gyro screens in India are widely used for quality control and production efficiency.

How Does a Vibratory Feeder Work?

The working principle of a vibratory feeder revolves around the use of vibrations to move material. The system typically consists of a vibrating tray or bowl, an electromagnetic or mechanical drive unit, and a control unit.

When electrical power is supplied, the drive unit produces vibrations that are transmitted to the tray or bowl. These vibrations create a linear or oscillating motion that propels the material forward. The amplitude and frequency of the vibration can be adjusted to control the feed rate.

The beauty of this system lies in its ability to transport materials without causing degradation, spillage, or blockage. Unlike conveyor belts, vibratory feeders can handle sticky or irregularly shaped items with ease. Also, the system is energy efficient and low-maintenance due to fewer moving parts.

Why Selecting the Right Gyro Screen Manufacturer Matters

Your choice of a gyro screen manufacturer in India directly impacts your production efficiency, product quality, and operational costs. A reliable manufacturer ensures:

- Consistent product quality with advanced engineering standards.

- Durable and efficient machines that minimize downtime.

- Customized solutions tailored to industry-specific requirements.

- After-sales support for installation, training, and service.

- Competitive pricing without compromising on quality.

Choosing the wrong manufacturer, on the other hand, can lead to frequent breakdowns, high maintenance costs, and poor screening results.

Key Factors to Consider When Choosing a Gyro Screen Manufacturer in India

Industry Experience and Expertise

Look for a manufacturer with proven experience in producing gyro screens and screening equipment in India. Industry expertise ensures they understand specific challenges and can recommend the right solutions.

Quality Standards and Certifications

Check whether the company follows international manufacturing standards and holds certifications for quality assurance. This guarantees machines are designed for reliability, safety, and durability.

Customization Options

Every business has unique needs. The best gyro screen manufacturers in India offer customization in terms of:

- Screen size and mesh type.

- Number of decks.

- Material of construction (stainless steel, mild steel, etc.).

- Specialized coatings for corrosive or abrasive materials.

Technology and Innovation

Modern gyro screen machines are equipped with advanced vibration technology, noise reduction, and energy efficiency features. Choose a manufacturer that invests in R&D and delivers innovative solutions.

Client Portfolio and Testimonials

A manufacturer’s credibility can often be judged by their existing clients. Reputed gyroscreen suppliers in India usually serve industries like plastics, food, chemicals, and pharmaceuticals. Positive client feedback speaks volumes about reliability.

After-Sales Service and Support

Even the best equipment needs proper installation, training, and occasional service. A reliable gyro screen manufacturer provides comprehensive support including spare parts availability, technical training, and maintenance services.

Pricing and Value for Money

While cost is important, the cheapest option is not always the best. Look for a manufacturer that balances affordability with quality, ensuring long-term returns on your investment.

Why Gyro Screens Are Crucial for Indian Industries

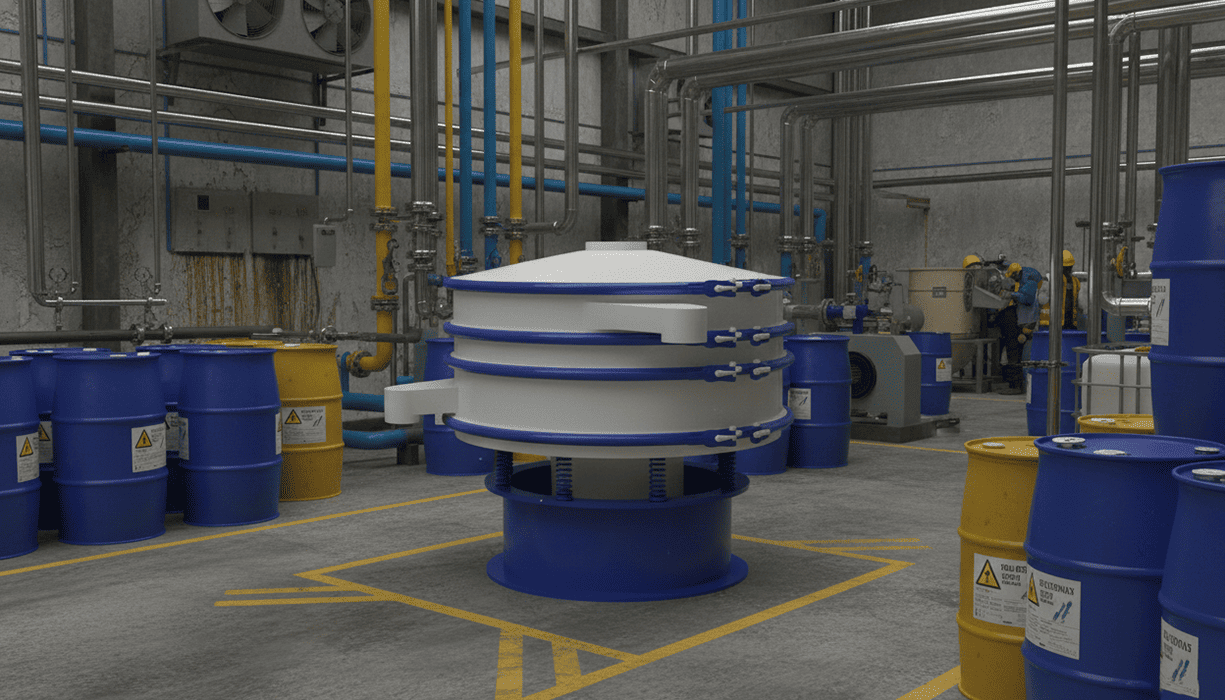

India’s growing industrial sectors demand precision and efficiency. Gyro screen machines in India play a vital role in industries such as:

- Plastics & Polymers – For separating recycled granules, powders, and raw materials.

- Food Processing – For sieving flour, spices, sugar, and grains.

- Pharmaceuticals – For screening powders to maintain product consistency.

- Chemicals & Fertilizers – For separating fine powders and granules.

- Minerals & Metals – For grading ore, sand, and other raw materials.

With such diverse applications, investing in the right screening equipment in India becomes a strategic decision for long-term success.

Invoit Plast Machinery – The Best Gyro Screen Manufacturer in India

When searching for a trusted partner in screening solutions, Invoit Plast Machinery Pvt. Ltd. stands out as a leading Gyro Screen Manufacturer in India. Based in Ahmedabad, the company has built a strong reputation for delivering high-quality, durable, and efficient machines across industries.

What Makes Invoit Plast Machinery the Preferred Choice?

- Expertise and Experience – Years of proven excellence in manufacturing gyroscreens and other plastic processing machinery.

- Premium Quality Standards – Each machine undergoes stringent quality checks to ensure consistent performance.

- Customized Solutions – From single-deck to multi-deck screens, customized designs are available to meet unique industrial needs.

- Advanced Technology – Modern designs ensure high screening efficiency with low noise and energy consumption.

- Robust After-Sales Support – Comprehensive installation guidance, training, spare parts, and technical support.

- Affordable Pricing – Offering competitive pricing without compromising on quality.

By choosing Invoit Plast Machinery, you partner with one of the most reliable screening equipment suppliers in India, ensuring smooth operations and maximum ROI.

How to Finalize Your Gyro Screen Supplier in India

Here’s a quick checklist to evaluate before making your decision:

- Compare multiple gyro screen manufacturers for quality, price, and service.

- Ask for technical specifications and customization options.

- Request client references or case studies.

- Evaluate warranty terms and after-sales service availability.

- Consider the long-term value, not just upfront pricing.

When all these factors align, you can be confident you are investing in the best gyro screen machine for your business.

Final Thoughts

Selecting the right gyro screen manufacturer in India is not just about buying equipment—it’s about building a long-term partnership that supports your business growth. The right choice ensures efficiency, reliability, and consistent product quality.

If you are searching for a trusted name in gyro screen machines in India, look no further than Invoit Plast Machinery Pvt. Ltd. Their commitment to quality, innovation, and customer satisfaction makes them the preferred choice for industries across the nation.

FAQs

A gyro screen machine is used for separating, grading, and filtering powders, granules, and liquids. It provides high-efficiency screening for industries like plastics, chemicals, food, and pharmaceuticals.

To choose the right gyro screen manufacturer in India, check their industry experience, quality standards, customization options, technology, after-sales service, and client reviews. A trusted name like Invoit Plast Machinery offers reliable and cost-effective solutions.

Gyro screens are widely used in plastics, polymers, food processing, pharmaceuticals, chemicals, fertilizers, minerals, and metal industries for precision screening and material separation.

Invoit Plast Machinery Pvt. Ltd. is one of the leading Gyro Screen Manufacturers in India, known for durable machines, advanced technology, customized solutions, and robust after-sales support, ensuring maximum ROI for businesses.

Unlike traditional screening equipment, a gyroscreen uses multi-plane gyratory motion for more accurate and efficient separation. It is compact, low-maintenance, and versatile, making it suitable for a wide range of industries.