Complete Guide to Plastic Granulator Machine for Industrial Use

In today’s competitive plastic manufacturing and recycling industry, choosing the right granulator machine is critical for efficiency, quality, and long-term profitability. Medium duty granulators are widely used across industries because they strike the perfect balance between power and efficiency—offering reliable performance without the high operational costs of heavy-duty models.

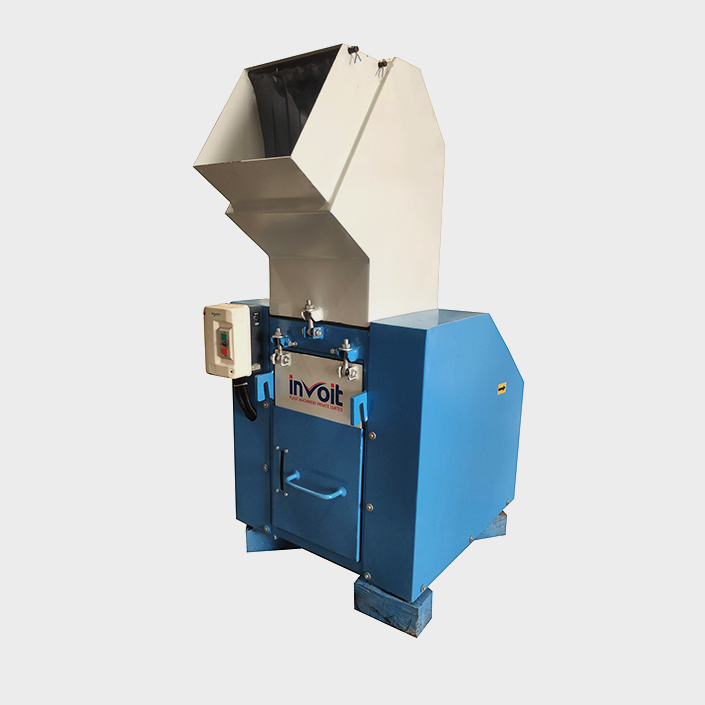

If you are evaluating options for your factory, you need to carefully consider various aspects like machine type, performance, and manufacturer reputation. In this guide, we will help you understand how to select the best medium duty granulator machine for your business, while also highlighting why Invoit Plast Machinery Pvt. Ltd. is one of the top Medium Duty Granulator Machine Manufacturers in India.

Understanding Medium Duty Granulator Machines

A medium duty granulator machine is designed to process plastic waste, sprues, and regrind materials in medium-volume production environments. Unlike slow-speed or heavy-duty granulators, these machines provide:

- Moderate throughput capacity suitable for mid-sized factories.

- High efficiency in handling common thermoplastics.

- Durability for continuous operation.

- Cost-effectiveness compared to heavy-duty alternatives.

They are ideal for applications in industries such as:

- Plastic molding & extrusion

- Packaging and film production

- Pipe and fitting manufacturing

- Automotive plastic parts recycling

- Consumer goods manufacturing

Why Medium Duty Granulators Are Important

Medium duty granulators play a critical role in helping industries:

- Reduce waste costs by reprocessing plastic scraps into reusable granules.

- Enhance sustainability through eco-friendly recycling processes.

- Improve operational efficiency by maintaining consistent particle size.

- Lower raw material expenses by enabling closed-loop recycling.

For businesses that want reliable performance without overspending, medium duty granulators are the smart choice.

Key Factors to Consider Before Selecting a Medium Duty Granulator

When selecting a plastic granulator machine, industry professionals and engineers should evaluate several technical and practical aspects.

Machine Capacity and Throughput

Evaluate how much plastic waste your business generates daily. A machine that is too small may lead to bottlenecks, while an oversized one could increase unnecessary energy costs.

Cutting Chamber Design

Look for advanced cutting chamber designs that minimize dust and ensure uniform granule sizes. A well-designed chamber also reduces wear and tear on blades.

Motor Power and Energy Efficiency

The motor defines the machine’s cutting power. For medium duty applications, machines with optimized motor performance ensure the best balance between efficiency and energy savings.

Blade Material and Maintenance

Blades should be made of high-quality hardened steel. Easy accessibility for maintenance and sharpening ensures longer life and reduced downtime.

Noise and Safety Features

Modern granulators are equipped with soundproofing and safety mechanisms. This ensures a safer and more comfortable working environment.

Ease of Operation and Cleaning

Choose a machine that allows quick cleaning, blade changes, and minimal downtime during material shifts.

Manufacturer’s Reputation and Support

Working with a reliable Plastic Granulator Machine Manufacturer in India ensures long-term service, spare parts availability, and technical expertise.

High Speed Granulator Machine: The Right Choice for Many Industries

For businesses that require faster processing with precise results, a High Speed Granulator Machine can be a great investment. These machines offer:

- High-speed cutting for uniform granules.

- Robust design to handle diverse materials.

- Compact footprint suitable for medium-scale production units.

When choosing a High Speed Granulator Machine in India, ensure that it meets safety standards and has proven energy efficiency.

Benefits of Choosing the Right Manufacturer

A high-quality granulator machine is only as good as the company that manufactures it. Selecting a trusted High Speed Granulator Machine Manufacturer in India provides several advantages:

- Consistent Quality: Machines designed with precision engineering and high-grade materials.

- Customized Solutions: Tailored designs to match your production needs.

- After-Sales Support: Reliable spare parts and technical service.

- Better ROI: Long-lasting machines that reduce replacement costs.

Why Choose Invoit Plast Machinery Pvt. Ltd.?

When it comes to Medium Duty Granulator Machines or High Speed Granulator Machines in India, Invoit Plast Machinery Pvt. Ltd. stands out as a trusted manufacturer.

Here’s why:

- Expertise: Years of experience in designing world-class plastic recycling equipment.

- Advanced Technology: State-of-the-art engineering for superior performance.

- Customization: Machines designed to match your exact production requirements.

- Quality Assurance: Strict adherence to international standards and testing protocols.

- Strong Market Presence: Recognized as a leading Plastic Granulator Machine Manufacturer in India with clients across industries.

High Speed Granulator India – Growing Demand

The demand for High Speed Granulator India is rising due to increasing focus on sustainability and recycling. Indian industries are actively investing in advanced granulators to reduce waste and cut down material costs. By choosing a reliable partner like Invoit Plast Machinery, businesses can stay ahead in this competitive landscape.

Tips for Maximizing Your Granulator Machine’s Efficiency

Once you have selected the right plastic granulator machine, consider the following tips to maximize its lifespan and performance:

- Regular Maintenance – Schedule blade sharpening and chamber cleaning.

- Proper Training – Ensure operators are trained on safe and efficient usage.

- Consistent Material Feeding – Avoid overloading to prevent motor strain.

- Lubrication and Inspection – Check moving parts regularly for wear and tear.

- Use Genuine Spare Parts – Always rely on the manufacturer’s spare parts for replacements.

Final Thoughts

Selecting the best Medium Duty Granulator Machine is a strategic decision that impacts production efficiency, waste reduction, and profitability. By considering factors like machine capacity, blade design, energy efficiency, and manufacturer reputation, businesses can make informed decisions.

With the growing need for Plastic Granulator Machines in India, investing in a reliable manufacturer is crucial. That’s why Invoit Plast Machinery Pvt. Ltd. is trusted by industries across the country for delivering robust, efficient, and cost-effective granulators.

FAQs

A medium duty granulator machine is a plastic recycling machine designed to process moderate volumes of plastic waste, sprues, and rejects. It is widely used in injection molding, extrusion, and packaging industries to convert scrap into reusable granules.

A high speed granulator machine uses fast-rotating blades to cut plastic waste into uniform granules. The high-speed operation ensures consistent particle size, efficient reprocessing, and better output for recycling or reuse in production.

Medium duty granulators provide an ideal balance between power and efficiency. Benefits include reduced waste disposal costs, lower raw material usage through in-house recycling, consistent granule size, and eco-friendly operations.

When selecting a plastic granulator machine, consider factors like machine capacity, blade material, motor power, noise levels, ease of maintenance, and the manufacturer’s reputation. Always choose a trusted Plastic Granulator Machine Manufacturer in India for reliable performance.

Industries that commonly use medium duty granulators include:

- Plastic molding & extrusion units

- Packaging and film manufacturers

- Pipe & fitting manufacturers

- Automotive plastic component makers

- Consumer goods manufacturers

A medium duty granulator is best suited for mid-volume recycling needs, offering cost-effectiveness and efficiency. Heavy-duty granulators, on the other hand, are designed for high-capacity, industrial-scale operations that require processing large and tough plastic materials.

Invoit Plast Machinery Pvt. Ltd. is one of the leading Medium Duty Granulator Machine Manufacturers in India. The company offers advanced technology, durable machines, customized solutions, and excellent after-sales service, making it the trusted choice for industries nationwide.

The price of a high speed granulator machine in India depends on capacity, motor size, blade design, and customization requirements. For an accurate quote, it is best to contact a trusted manufacturer like Invoit Plast Machinery.

To extend the life of your granulator, follow these practices:

- Regular blade sharpening and chamber cleaning

- Scheduled preventive maintenance

- Using genuine spare parts from the manufacturer

- Proper operator training and safety checks

You can buy high-quality medium duty and high speed granulator machines directly from Invoit Plast Machinery Pvt. Ltd., a leading Plastic Granulator Machine Manufacturer in India.