How to Select the Right Extruder Machine Manufacturer for Your Business

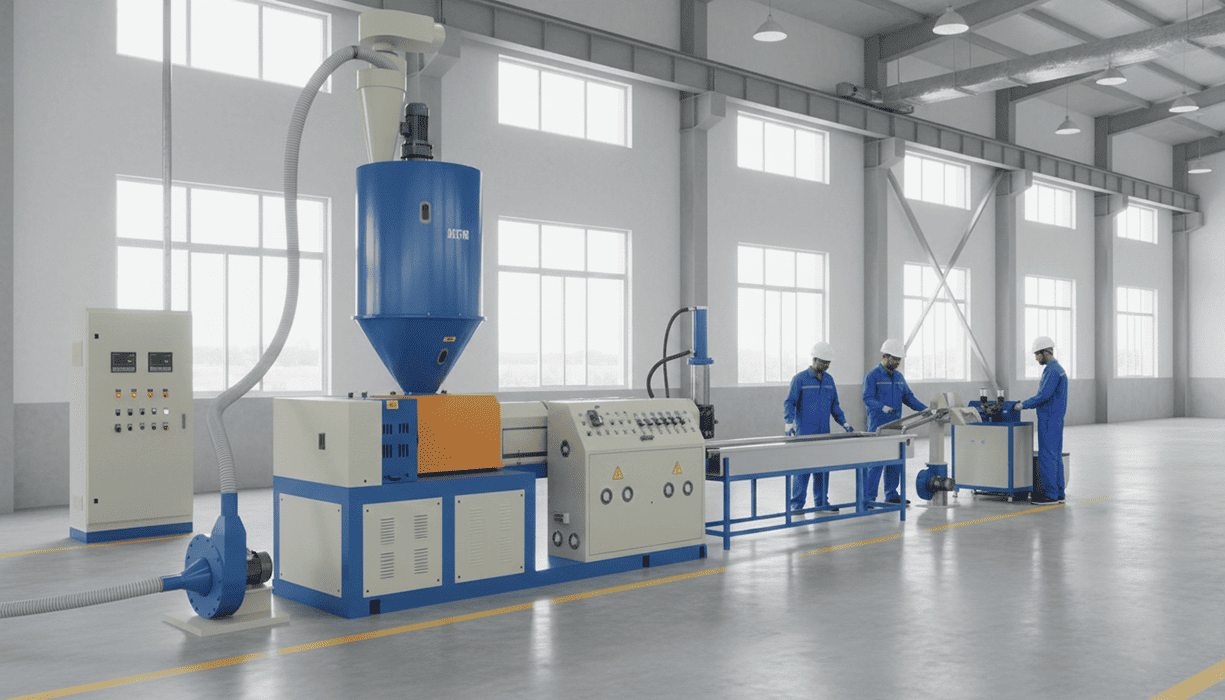

In the plastic processing industry, choosing the right extruder machine manufacturer in India is one of the most important decisions you will make. An extruder machine is not just a piece of equipment—it is the backbone of production for industries manufacturing pipes, profiles, films, wires, cables, and a wide variety of plastic products. The reliability, efficiency, and durability of your plastic extruder directly affect your business performance, production costs, and final product quality.

With several manufacturers offering different models and specifications, selecting the right partner can be challenging. Businesses must look beyond the machine’s price tag and evaluate the manufacturer’s technical expertise, after-sales support, and ability to deliver customized solutions.

This blog will guide you through the critical factors to consider when selecting the right extruder machine in India for your factory, while also highlighting why companies like Invoit Plast Machinery Pvt. Ltd., the best extruder machine manufacturer in India, are trusted by industry leaders.

Understanding the Role of an Extruder Machine

A plastic extruder works by melting raw plastic material and shaping it into continuous products such as sheets, pipes, tubes, and films. Its performance determines not just the consistency of the product but also the overall efficiency of the production line.

Different industries require different types of extrusion machines—single-screw extruders, twin-screw extruders, and specialized designs for PVC, HDPE, PP, or PET applications. When you choose the right extruder machine manufacturer in India, you gain access to both high-quality machinery and the technical know-how that ensures your equipment delivers optimal performance for your unique production needs.

Experience and Expertise of the Manufacturer

One of the first aspects to evaluate is the manufacturer’s experience in building plastic extruders. A company with a proven track record in extrusion technology understands the challenges of material processing, energy efficiency, and long-term reliability.

Manufacturers with decades of experience are better equipped to provide machines that meet international standards and adapt to the evolving needs of the plastic industry. Choosing a company with expertise ensures that the machinery you invest in is designed to last and consistently deliver high-quality results.

Quality of Manufacturing Standards

The performance of an extruder machine in India depends heavily on the precision of its design and the quality of materials used. High-grade alloys, robust construction, and advanced heating and cooling systems contribute to the durability and efficiency of the machine.

A reliable extruder machine manufacturer in India will always follow strict quality control protocols at every stage of production. They will use advanced machining equipment, test components thoroughly, and ensure compliance with industry standards before delivery. This guarantees that your extrusion line operates with minimal downtime and maximum consistency.

Customization for Industry Needs

Not all extrusion processes are the same. Pipe manufacturers, packaging companies, and profile producers often require specialized features. The ability to customize an extruder machine according to your production requirements is a clear sign of a reliable manufacturer.

Whether it is designing screws and barrels for specific polymers, adding automation features, or integrating energy-efficient heating systems, the right manufacturer should offer flexibility. A plastic extruder tailored to your needs ensures better output quality and higher profitability in the long run.

Technology and Innovation

The plastic industry is evolving rapidly with automation, energy efficiency, and digital monitoring becoming key factors in production. Modern extruder machines in India are expected to come with advanced features such as automatic temperature controls, touch-screen panels, real-time monitoring, and IoT-based data collection.

When choosing an extruder machine manufacturer in India, it is important to check how much they invest in research and development. A forward-thinking company ensures that your production line stays competitive and future-ready.

After-Sales Support and Service

Even the most advanced plastic extruder requires timely maintenance and technical support. Downtime can cause significant production losses, making after-sales service a critical factor in your decision-making process.

The right manufacturer will provide quick access to spare parts, technical support teams, and preventive maintenance services. This ensures uninterrupted production and reduces long-term operational costs. When evaluating suppliers, ask about their service response times, availability of spare parts, and training programs for your staff.

Reputation and Client Trust

In today’s competitive market, reputation speaks volumes. A reliable extruder machine manufacturer in India will have a strong portfolio of clients across industries and positive feedback from existing users.

Client testimonials, case studies, and market presence help you judge whether the manufacturer is trustworthy. A brand that is known for quality, reliability, and long-term partnerships is far more valuable than one offering lower prices but inconsistent results.

Cost vs. Value

While businesses often focus on the extruder machine price, it is more important to evaluate value. A machine that consumes less energy, operates with fewer breakdowns, and delivers consistent quality will save you more in the long term compared to a cheaper but less reliable alternative.

The right extruder machine manufacturer in India should provide you with machines that offer high performance, energy efficiency, and durability, ensuring maximum return on your investment.

Why Choose Invoit Plast Machinery Pvt. Ltd.?

When selecting the best partner for your extrusion needs, Invoit Plast Machinery Pvt. Ltd. stands out as one of the leading and most trusted names in India. Known as the best extruder machine manufacturer in India, the company combines advanced technology, strong engineering expertise, and a customer-first approach.

Their plastic extruders are built with high-quality materials, precision engineering, and modern automation systems that meet global standards. From delivering customized solutions to offering excellent after-sales service, Invoit Plast has established itself as a dependable partner for businesses across industries.

If your goal is to maximize efficiency, reduce downtime, and ensure consistent product quality, Invoit Plast provides the perfect blend of performance and reliability.

Long-Term Partnership and Growth

Investing in an extruder machine in India is not just about buying equipment—it is about building a long-term relationship with a manufacturer who understands your business. The right manufacturer should grow with you, offering upgrades, new technologies, and continuous support as your production needs evolve.

A trusted extruder machine manufacturer in India like Invoit Plast Machinery Pvt. Ltd. ensures that your investment continues to add value for years to come, making them more than just a supplier but a strategic partner in your success.

Final Thoughts

Selecting the right extruder machine manufacturer in India is a decision that directly impacts the success of your business. By focusing on expertise, quality, customization, innovation, service, and trust, you can ensure that your production line operates at peak performance.

An extruder machine is not just an investment in machinery—it is an investment in your business future. That is why partnering with a reliable manufacturer like Invoit Plast Machinery Pvt. Ltd., the best extruder machine manufacturer in India, is a smart choice for businesses looking for consistent performance, innovation, and long-term value.

Whether you are in packaging, construction, or plastic product manufacturing, choosing the right plastic extruder will give your business the edge it needs to stay competitive in today’s demanding market.

FAQs

An extruder machine is used in the plastic industry to melt raw material and shape it into continuous products like pipes, films, sheets, profiles, and wires. It ensures consistent product quality and high-volume production.

You should consider factors such as the type of plastic you process, production capacity, energy efficiency, customization needs, and after-sales support when selecting a plastic extruder for your business.

The right extruder machine manufacturer in India ensures reliable performance, durability, timely support, and access to the latest technology, which directly impacts production efficiency and profitability.

Common types include single-screw extruders, twin-screw extruders, PVC extruders, and high-speed extruders for different applications like pipe manufacturing, packaging films, and plastic recycling.

Look for ISO certifications, industry experience, client reviews, use of high-grade materials, and strict quality control processes before selecting an extruder machine manufacturer in India.

After-sales service is crucial for minimizing downtime, ensuring quick availability of spare parts, and providing training. A reliable extruder machine in India must come with strong service support.

Yes, reputed manufacturers like Invoit Plast Machinery Pvt. Ltd. offer customized plastic extruders designed to match specific production requirements, materials, and automation levels.

The price of an extruder machine in India depends on size, technology, and customization. Instead of focusing only on cost, businesses should consider long-term value, energy savings, and machine durability.

Extruder machines are widely used in industries like packaging, construction (pipes & profiles), automotive, agriculture (films & sheets), and recycling of plastic waste.

Invoit Plast Machinery Pvt. Ltd. is widely recognized as the best extruder machine manufacturer in India, offering high-quality, durable, and efficient machines backed by excellent service and technical expertise.