How a Vibro Screen Can Cut Down Downtime and Improve Productivity in Your Plant

In modern manufacturing environments, operational efficiency and minimal downtime are the cornerstones of profitability. Whether you’re in plastics, pharmaceuticals, food processing, or chemical manufacturing, the need for precise material separation and uniform particle size is crucial. This is where the Vibro Screen — also known as a Vibrating Screen or Vibratory Separator — becomes an indispensable asset.

An intelligently designed Vibro Screen helps reduce production interruptions, prevent material wastage, and ensure smoother processing. For companies that aim to improve throughput and maintain consistent quality, investing in a high efficiency Vibro Screen from a trusted manufacturer like Invoit Plast Machinery Pvt. Ltd. can be a game-changer.

What is a Vibro Screen and How Does It Work?

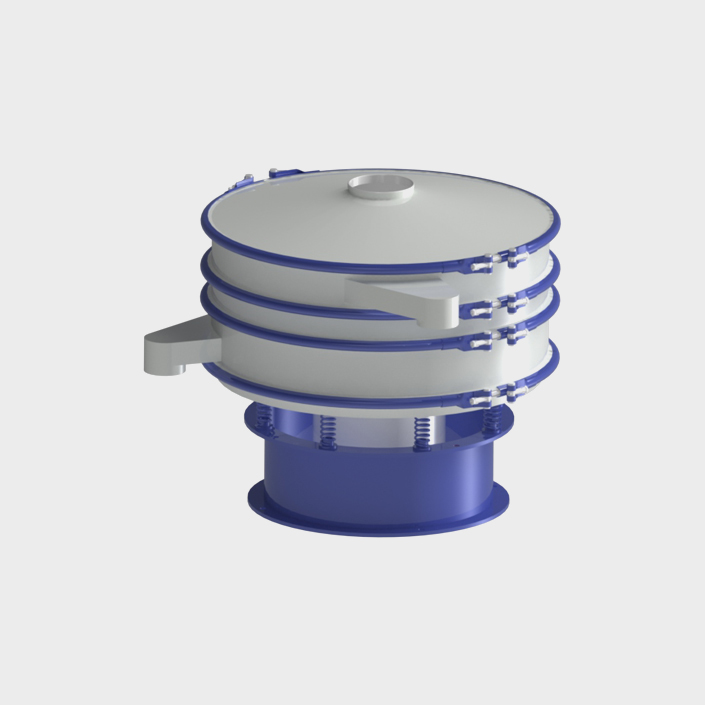

A Vibro Screen is a circular vibrating screening machine that separates materials by size, shape, and density using multi-plane vibration motion. It typically consists of a motor, screen decks, springs, and a robust frame. When powered, the motor generates vibrations that cause the materials to move across the screen surface, separating fine particles from coarse ones.

Unlike traditional sieving or filtering systems, a high efficiency Vibro Screen delivers continuous operation with minimal manual intervention. This not only saves time but also reduces operational stress on workers and equipment.

How a Vibro Screen Reduces Downtime

Downtime in industrial plants can be extremely costly — every minute lost means reduced output and wasted resources. Here’s how a Vibro Screen helps minimize it:

Automated and Continuous Screening

Manual sieving and sorting often cause bottlenecks in the production line. A Vibrating Screen automates this process, offering continuous and precise separation of materials without the need for frequent stoppages.

This automation ensures uninterrupted flow in processes like plastic granule screening, powder grading, or raw material filtration — keeping the production line running efficiently.

Minimal Maintenance Requirements

Modern Vibro Screens are designed with durability and simplicity in mind. They feature easy-to-clean screens, quick-release clamps, and robust motors that demand little maintenance. This means less time spent on servicing and more time in production mode.

When you invest in a high efficiency Vibro Screen from Invoit Plast Machinery Pvt. Ltd., you get a machine built with long-lasting components and smart design that minimizes breakdowns.

Quick Screen Change and Cleaning

Traditional screen changers can take hours to dismantle, clean, and reassemble. However, modern Vibratory Separator designs allow rapid screen changes — reducing downtime during product changeovers or cleaning cycles. This flexibility is especially valuable for plants handling multiple materials or grades.

Improved Reliability and Fewer Breakdowns

Downtime often results from machine breakdowns caused by imbalance, overloading, or clogging. A Vibro Screen operates on a balanced vibration system, distributing loads evenly and reducing wear and tear. The result is consistent performance with minimal risk of unplanned halts.

How a Vibro Screen Improves Productivity

Cutting downtime is only half the story. The other half is how a Vibro Screen helps your plant achieve greater throughput and product consistency.

Enhanced Screening Efficiency

A high efficiency Vibro Screen ensures precise particle separation. Whether you’re grading plastic granules, sieving powders, or removing impurities, it delivers consistent quality output at a faster rate than conventional screening methods.

The result? Improved yield, fewer rejections, and higher productivity per shift.

Uniform Material Flow

The multi-plane vibration pattern of a Vibrating Screen ensures even material distribution across the mesh surface. This prevents clumping and allows for smooth flow, which is especially useful in industries like plastics, chemicals, and food where product consistency is critical.

Energy-Efficient Operations

Modern Vibro Screens are designed to consume less power while delivering maximum output. The use of efficient motors and well-balanced design means your plant can process more material using less energy — directly boosting operational profitability.

Better Product Quality

When materials are screened accurately, the final product quality automatically improves. Consistent particle sizes or uniform granules enhance downstream processing, whether in molding, extrusion, or packaging operations.

By installing an Invoit Plast high efficiency Vibro Screen, you ensure that your production line runs at optimal capacity without compromising on output quality.

Applications of Vibro Screens Across Industries

The versatility of Vibro Screens makes them suitable for a wide range of industrial applications:

- Plastic Industry: For grading and filtering plastic granules, pellets, and powders.

- Food Industry: For separating spices, flour, sugar, and grains.

- Pharmaceutical Industry: For ensuring purity and particle size uniformity.

- Chemical Industry: For filtering and classifying powders or liquids.

- Recycling Industry: For separating impurities and ensuring consistent recycled material output.

This adaptability makes the Vibro Screen a must-have machine in any modern production setup.

Understanding Vibro Screen Price and Value

Many buyers focus only on the Vibro Screen price, but the true value lies in its long-term performance and reliability. A cheaper machine might cost less upfront but can result in more frequent maintenance, downtime, and energy waste.

At Invoit Plast Machinery Pvt. Ltd., the focus is on delivering cost-effective yet premium-quality Vibro Screens that balance performance and affordability. Our machines are engineered with high-grade materials, precision components, and efficient motor systems that ensure superior screening at a competitive price point.

When evaluating the Vibro Screen price, consider:

- Durability: How long will the machine last under continuous operation?

- Ease of Maintenance: Are parts easily accessible and replaceable?

- Efficiency: Does it reduce manual intervention and energy usage?

- After-Sales Support: Does the manufacturer provide prompt service and spare parts?

Choosing the right Vibratory Separator manufacturer ensures not only better ROI but also long-term peace of mind.

Why Choose Invoit Plast Machinery Pvt. Ltd.?

Invoit Plast Machinery Pvt. Ltd., based in Ahmedabad, India, is one of the most trusted Vibro Screen manufacturers with years of expertise in plastic processing and material handling equipment. We design our high efficiency Vibro Screens to meet the unique demands of modern industries — blending advanced engineering with cost efficiency.

Key Advantages of Choosing Invoit Plast:

- Robust Construction: Designed for continuous operation with minimum vibration leakage.

- Customizable Designs: Available in multiple sizes, deck options, and mesh configurations.

- Energy Efficient Motors: Ensures low power consumption with high output.

- Easy Maintenance: Quick assembly and disassembly for cleaning and servicing.

- After-Sales Service: Dedicated support team and readily available spare parts.

Our Vibro Screens are widely used in plastics, chemicals, pharmaceuticals, and other sectors, proving our versatility and reliability.

Tips for Maximizing Vibro Screen Performance

To get the most out of your Vibrating Screen, keep these tips in mind:

- Regularly inspect screens for wear or damage.

- Ensure proper motor alignment and balance.

- Use high-quality mesh to avoid frequent replacements.

- Clean the screen deck after each shift to prevent material buildup.

- Follow manufacturer-recommended maintenance schedules.

By maintaining your equipment properly, you’ll extend its lifespan and continue to enjoy high screening efficiency with minimal downtime.

Final Thoughts

Investing in a Vibro Screen is more than just adding another piece of machinery — it’s a step toward a more productive, efficient, and profitable manufacturing process. By reducing downtime, improving screening accuracy, and ensuring smooth material flow, the high efficiency Vibro Screen becomes an invaluable part of your production line.

If you’re looking for superior quality, reliable performance, and competitive Vibro Screen price, Invoit Plast Machinery Pvt. Ltd. is your trusted partner.

As a leading Vibratory Separator manufacturer in India, we’re committed to helping your plant achieve higher productivity and lower operational costs — with machines that deliver consistent results, shift after shift.

FAQs

A Vibro Screen, also called a Vibrating Screen or Vibratory Separator, is a circular screening machine used to separate materials by particle size through vibration. It works by generating multi-plane vibrations that move materials across different mesh layers, allowing fine and coarse particles to separate efficiently.

A Vibro Screen reduces downtime by automating material screening, ensuring continuous operation with minimal maintenance. Its easy-to-clean design, quick screen change system, and robust motor reduce stoppages and equipment failures — keeping your production line running smoothly.

Vibro Screens are used across multiple industries, including plastics, chemicals, pharmaceuticals, food processing, and recycling. They help in grading powders, filtering liquids, separating granules, and ensuring uniform material quality.

The Vibro Screen price depends on machine size, screen layers, motor type, material grade (MS or SS), and customization options. Higher-capacity or multi-deck high efficiency Vibro Screens may cost more but deliver better performance and durability.

A high efficiency Vibro Screen improves productivity by offering faster material separation, consistent particle size, and continuous operation. It reduces manual labor, energy consumption, and process interruptions — resulting in higher output and better-quality products.

Invoit Plast Machinery Pvt. Ltd. is a leading Vibro Screen manufacturer in India known for durable, energy-efficient, and customizable screening machines. They offer high-quality Vibratory Separators with strong after-sales support and competitive pricing — ensuring long-term value for your plant.

Regular inspection and cleaning after each production cycle are recommended. Check for mesh wear, motor alignment, and balance periodically. Following the manufacturer’s maintenance schedule helps extend the lifespan and maintain the efficiency of your Vibrating Screen.