Industrial Plastic Crusher Machine: Specifications & Uses

In today’s industrial landscape, where plastic waste management has become a critical concern, plastic crusher machines play a pivotal role. These machines are not only crucial for plastic recycling industries but also highly valuable for plastic product manufacturers, molding units, and waste handlers. Designed to crush plastic scraps into reusable granules or flakes, industrial plastic crusher machines are engineered for durability, efficiency, and performance.

Let’s explore in detail the specifications, working mechanism, and varied uses of these powerful machines in the plastic industry.

Understanding the Function of an Industrial Plastic Crusher Machine

An industrial plastic crusher machine is a heavy-duty mechanical device used to break down large plastic pieces, rejected molded products, or defective plastic materials into smaller, manageable sizes. These crushed materials, often in the form of flakes or granules, can be reused in manufacturing processes or sent for recycling.

The machine uses high-speed rotating blades to slice through plastic items, including PP, PE, PVC, HDPE, LDPE, PET, and even hard engineering plastics. It operates with high torque, delivering consistent output while ensuring uniform size reduction.

Key Technical Specifications of a Plastic Crusher Machine

To choose the right plastic crusher machine for your business, it is essential to understand its core specifications. While different models vary depending on size and output, here are the most common specifications featured in top-grade industrial models:

- Motor Power: Typically ranges from 5 HP to 100 HP, depending on the machine’s size and throughput requirements.

- Blade Type and Material: Rotating and stationary blades made from hardened tool steel (D2 or SKD-11) for long-lasting performance.

- Crushing Chamber Size: Varies according to material type, machine capacity, and feeding size—usually starts from 200mm width to 1000mm+ for heavy-duty machines.

- Cutting Speed: Between 400–800 RPM, optimized for efficient cutting without generating excessive heat.

- Output Capacity: From 50 kg/hr to over 1000 kg/hr, depending on machine size, motor capacity, and material hardness.

- Screen Mesh Size: Customizable screens (ranging 8mm–20mm) ensure desired output size for recycling or reuse.

- Noise Reduction Features: Many machines are fitted with soundproof enclosures or rubber padding to reduce operational noise.

- Feeding System: Manual, hopper-fed, or conveyor belt-supported feeding for larger systems.

- Safety Features: Emergency stop switch, overload protection, and interlocking systems for operator safety.

These specifications determine the efficiency, productivity, and lifespan of the crusher machine. Businesses must choose a machine that matches their production needs while offering flexibility in processing different plastic materials.

Different Types of Plastics That Can Be Crushed

One of the key advantages of a plastic crusher machine is its ability to handle various types of plastics, making it extremely versatile. Here are some common plastic materials processed using these machines:

- Polyethylene (PE): HDPE and LDPE used in bottles, pipes, and films.

- Polypropylene (PP): Used in automotive parts, containers, and packaging.

- Polyvinyl Chloride (PVC): Pipes, profiles, and window frames.

- Polyethylene Terephthalate (PET): Soft drink bottles and packaging trays.

- Acrylonitrile Butadiene Styrene (ABS): Used in household appliances and toys.

- Engineering Plastics: Such as PC, PA, and POM used in industrial parts and tools.

This wide material compatibility makes plastic crusher machines essential equipment across multiple sectors.

Key Uses of Industrial Plastic Crusher Machines

The applications of industrial plastic crusher machines are diverse and impactful across different industries. Let’s explore how these machines contribute to operational efficiency and sustainability:

Recycling and Reprocessing

The primary use of a plastic crusher is in the plastic recycling process. By crushing plastic waste into granules, these machines enable companies to reprocess materials into new products, reducing dependency on virgin plastic. This not only cuts costs but also helps minimize plastic pollution and landfill waste.

Waste Volume Reduction

In industries such as packaging, injection molding, and blow molding, scrap and defective items are unavoidable. Plastic crusher machines drastically reduce the volume of waste, making storage and transport more efficient and cost-effective. Crushed plastic occupies less space and can be easily transferred to recycling centers or reused internally.

Enhancing Production Efficiency

Plastic manufacturing units often recycle their own scrap during production. The on-site use of a plastic crusher means rejected products can be immediately reprocessed, eliminating delays and reducing material wastage. This boosts overall plant efficiency and streamlines operations.

Cost-Saving in Material Procurement

By using a crusher machine to reuse plastic scrap, manufacturers can save on raw material costs. Recycled granules produced by the machine can be blended with virgin materials, offering a sustainable and cost-effective alternative in the production process.

Pre-processing for Pulverizing and Compounding

Before plastics are pulverized into fine powders or used in compounding processes, they must be pre-sized. A plastic crusher machine offers the ideal pre-processing step, producing uniformly sized flakes that ensure consistent quality in downstream applications like plastic powder making machines or PVC pulverizer machine.

Supporting Environmental Goals

The rising demand for sustainable business practices has made plastic crushers a key component in industrial eco-initiatives. By enabling efficient plastic waste management, these machines support compliance with environmental regulations and help businesses contribute to circular economy models.

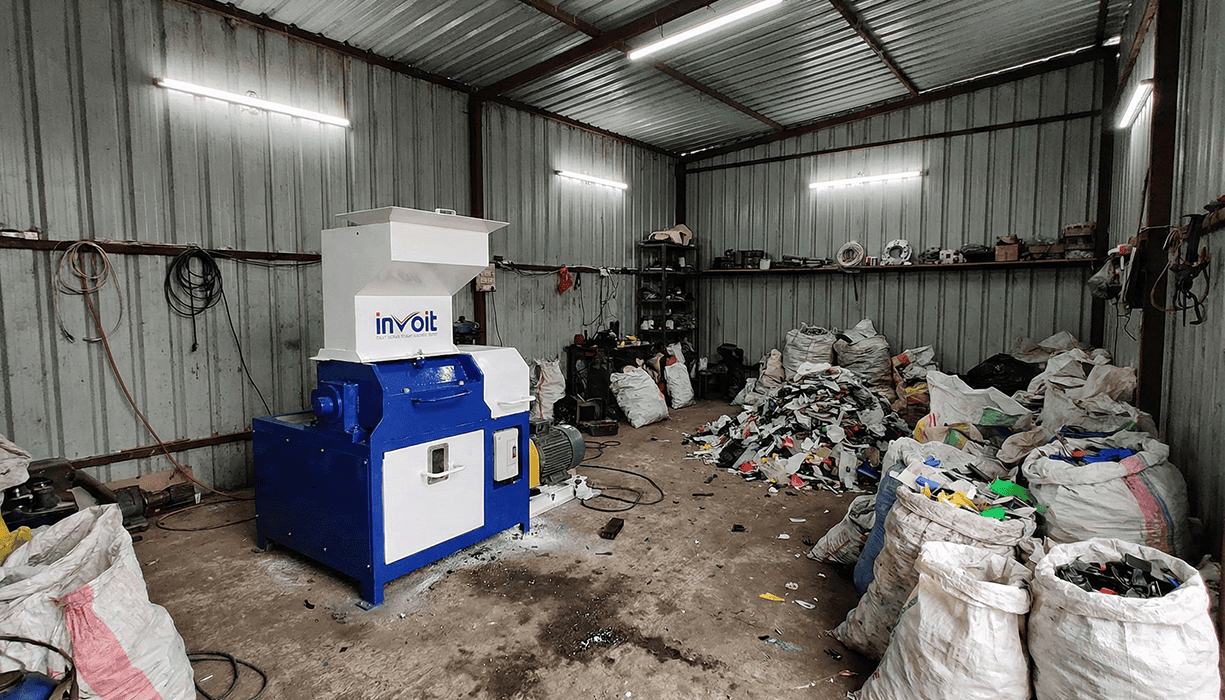

Why Invoit Plast Machinery Pvt Ltd Is the Best Plastic Crusher Machine Manufacturer in India

When it comes to investing in a reliable and high-performance plastic crusher machine, Invoit Plast Machinery Pvt Ltd stands out as a trusted name in India’s plastic processing industry. With years of expertise, cutting-edge manufacturing facilities, and a customer-first approach, Invoit Plast has earned a reputation for delivering superior-quality machines tailored to diverse industrial needs.

Their plastic crusher machines are designed with advanced engineering, offering robust structure, low maintenance, high efficiency, and safety-focused operation. Whether you need a compact model for small units or a heavy-duty crusher for large-scale recycling, Invoit Plast delivers machines that combine innovation with reliability.

Moreover, their prompt after-sales service, technical support, and customization options make them the go-to plastic crusher machine manufacturer for clients across India and beyond.

Maintenance and Safety Tips for Plastic Crusher Machines

To ensure long-lasting performance and operator safety, regular maintenance of the machine is essential. Here are some best practices:

- Routine Blade Sharpening: Maintain blade sharpness for consistent cutting.

- Lubrication: Regularly oil moving parts to prevent wear and friction.

- Check Motor Load: Ensure the machine isn’t overloaded during operations.

- Screen Cleaning: Prevent screen clogging by cleaning regularly.

- Operator Training: Provide safety training to machine operators.

- Inspection Schedule: Perform periodic checks for cracks, loose bolts, and electrical issues.

Adhering to these simple maintenance steps extends the life of the crusher and ensures optimal performance.

The Backbone of Plastic Recycling and Waste Reduction

An industrial plastic crusher machine is more than just a piece of equipment—it’s a crucial part of sustainable industrial operations. Whether it’s to reduce waste volume, support in-house recycling, or cut costs, the machine provides unmatched value across various applications. With advanced technology, high-speed efficiency, and rugged construction, these machines continue to revolutionize the plastic industry.

If you are looking for a powerful, efficient, and durable plastic crusher, look no further than Invoit Plast Machinery Pvt Ltd—the best plastic crusher machine manufacturer in India. Their machines are crafted with precision, designed for performance, and backed by expert support, making them the ideal partner for your plastic processing needs.

FAQs

An industrial plastic crusher machine is used to crush plastic waste—such as rejected molded items, film scraps, and packaging—into smaller granules or flakes for recycling or reuse. It plays a key role in plastic waste reduction and recycling operations.

These machines can process a wide variety of plastics, including HDPE, LDPE, PET, PP, PVC, ABS, and engineering plastics like PA and PC. Their robust blades and motors make them suitable for both soft and hard plastic materials.

Key specifications include:

- Motor power (5 HP to 100 HP)

- Blade material (D2 or SKD-11)

- Output capacity (50 to 1000+ kg/hr)

- Cutting speed (400–800 RPM)

- Adjustable screen mesh (8–20mm)

- Noise control and safety systems

By breaking down plastic waste into uniform granules, the machine simplifies material handling and prepares plastic for reprocessing, reducing waste volume, storage space, and raw material costs.

Yes, manufacturers often use plastic crushers in-house to recycle their own production scrap, improving material utilization, reducing delays, and cutting costs in injection molding and extrusion operations.

A plastic crusher is typically used for larger and tougher plastic materials, while a granulator handles smaller or thinner plastics. Crushers provide higher torque and are suitable for pre-processing hard or bulky items.

Crushing plastic into smaller flakes reduces its bulk, making storage and transportation easier and more cost-effective. This is especially beneficial for large-volume plastic producers and recyclers.

Yes, modern plastic crushers come with safety features like emergency stop switches, overload protection, soundproofing, and safety interlocks to ensure safe operation for industrial use.

Invoit Plast Machinery Pvt Ltd is a leading plastic crusher machine manufacturer in India, known for its high-performance machines, custom designs, reliable service, and expert support tailored to industrial plastic processing needs.

Routine maintenance—such as blade sharpening, motor inspection, lubrication, and screen cleaning—should be performed regularly. Preventive checks help extend the machine’s life and maintain consistent output quality.