Plastic Granulator Machine in Nigeria

Plastic Granulator Machine in Nigeria

One of the most important machines enabling effective recycling is the Plastic Granulator Machine in Nigeria. This machine transforms waste plastic into reusable granules that can be reprocessed into valuable products. For businesses looking to reduce raw material costs, improve sustainability, and meet Nigeria’s recycling goals, investing in the right granulator is not just an option—it is a necessity.

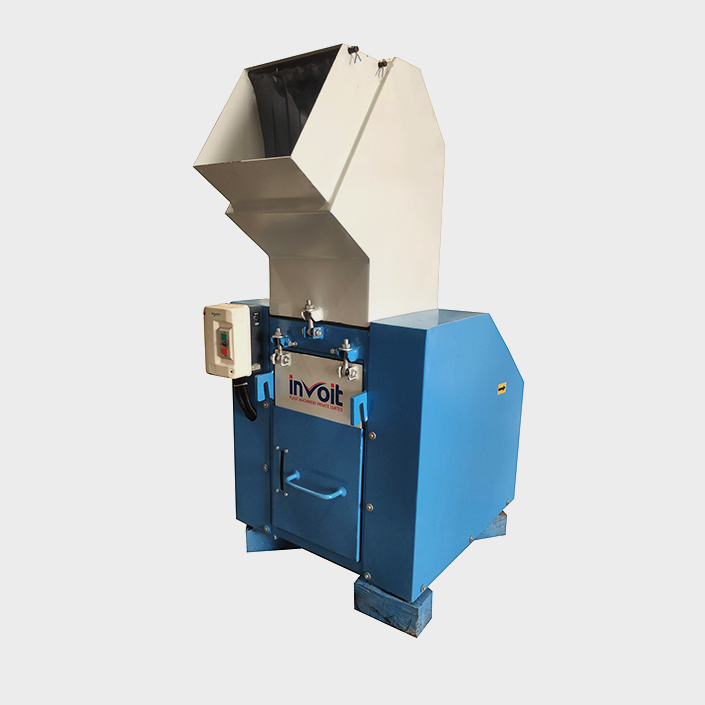

As a leading Plastic Granulator Machine Manufacturer Nigeria, Invoit Plast Machinery provides world-class solutions designed for the Nigerian market. With high efficiency, durability, and affordability, our machines are built to empower industries and recycling plants to achieve both economic and environmental benefits.

What is a Plastic Granulator Machine?

A Plastic Granulator Machine is specialized industrial equipment used to break down plastic waste into smaller granules or flakes. These granules can then be reused in manufacturing processes, reducing dependency on virgin plastic materials.

Unlike shredders, which cut materials into larger chunks, granulators produce uniformly sized plastic granules that can be directly fed into extruders, molding machines, or recycling systems.

Role of Plastic Granulator in Nigeria’s Industry

- Recycling Sector: Essential for processing post-consumer and post-industrial plastic waste.

- Manufacturing Sector: Reduces material costs by reusing scrap plastic.

- Packaging Industry: Helps in recycling PET bottles, films, and packaging waste.

- Construction & Automotive: Produces granules for pipes, fittings, and molded components.

For businesses that want to buy Plastic Granulator Machine in Nigeria, understanding its role is crucial in making the right investment decision.

Types of Plastic Granulator Machines by Invoit Plast Machinery

At Invoit Plast, we understand that every business in Nigeria has unique requirements based on production capacity, type of plastic waste, and operational scale. That’s why we offer three main categories of Plastic Granulator Machine in Nigeria:

Slow Speed Granulator Machine

- Best For: Small-scale operations, recycling near injection molding machines, low-volume plastic waste.

- Features: Operates at low RPM, minimizes noise, and prevents dust generation.

- Benefits:

- Ideal for delicate plastics like sprues and rejects.

- Energy-efficient and compact.

- Reduces contamination risk.

Medium Duty Granulator Machine

- Best For: Medium-sized factories and recycling plants in Nigeria.

- Features: Balanced speed, higher throughput than slow-speed models.

- Benefits:

- Suitable for moderate production capacities.

- Processes a wide range of plastics including PET, HDPE, and LDPE.

- Affordable and versatile, making it popular among Nigerian manufacturers.

Heavy Duty Granulator Machine

- Best For: Large recycling companies and industrial plants.

- Features: High horsepower motors, robust blades, and heavy-duty construction.

- Benefits:

- Handles large volumes of plastic waste.

- Processes tough materials such as thick pipes, drums, and heavy films.

- Ensures long-term durability with minimal downtime.

Whether you need a Plastic Waste Granulator Machine Nigeria for small workshops or an Industrial Plastic Granulator Machine Nigeria for large-scale recycling, Invoit Plast Machinery has the perfect solution.

Key Features of Invoit Plast Granulators

Our machines are engineered to meet the demands of the Nigerian market, combining technology, performance, and cost-effectiveness.

- High Efficiency : Ensures faster processing of large volumes of plastic waste.

- Low Maintenance Design : Easy-to-replace blades and simple operation reduce downtime.

- Energy-Saving Technology : Optimized motors and blade systems lower electricity costs.

- Durable Construction : Built with robust materials to withstand Nigeria’s tough industrial conditions.

- Safety Mechanisms : Includes advanced features for operator safety.

- Customizable Options : Available in different sizes and capacities.

With these features, our machines are not only Affordable Plastic Granulator Nigeria, but also long-term investments that deliver consistent returns.

Benefits of Using a Plastic Granulator Machine in Nigeria

Investing in a Plastic Recycling Granulator Machine in Nigeria offers numerous benefits for businesses, recycling companies, and the environment:

- Cost Savings – Reduce raw material costs by reusing recycled plastic granules.

- Environmental Responsibility – Contribute to Nigeria’s fight against plastic pollution.

- Increased Productivity – Convert waste into valuable resources quickly.

- Versatility – Suitable for bottles, films, containers, pipes, and more.

- Regulatory Compliance – Helps businesses align with Nigeria’s environmental policies.

For companies aiming to scale recycling operations, a High-Speed Plastic Granulator Nigeria is particularly valuable, as it allows for faster and more efficient processing.

Plastic Packaging Manufacturer

Blow Moulding

Plastic Bottle Producer

Household goods manufacturers

Automotive component Plastic

Waste Management & Recycling

Why Buy from a Reliable Plastic Granulator Machine Supplier Nigeria

The Nigerian market is growing, and with it comes the need for trusted industrial suppliers. Choosing a reliable Plastic Granulator Machine Supplier Nigeria is critical for long-term success.

Advantages of Buying from Invoit Plast Machinery:

- Proven Expertise: With years of global experience, we understand industrial recycling challenges.

- Local Support: Nigerian customers benefit from technical assistance, installation, and training.

- After-Sales Service: We provide maintenance, spare parts, and ongoing support.

- Customized Solutions: Tailored machines designed for Nigeria’s industrial needs.

- Competitive Pricing: We ensure you get an Affordable Plastic Granulator Nigeria without compromising quality.

Real-World Applications of Plastic Granulator Machines in Nigeria

Plastic granulation is not just a theoretical solution—it has practical applications across Nigeria’s industries:

- Recycling Plants: Turning plastic bottles, films, and containers into reusable granules.

- Packaging Industry: Reprocessing rejected packaging materials.

- Construction Materials: Recycling pipes, fittings, and sheets.

- Automotive Sector: Reusing plastic scrap for interior and exterior components.

- Agriculture: Recycling greenhouse films and irrigation pipes.

With these applications, it’s clear that a Plastic Waste Granulator Machine Nigeria is an essential tool for industries looking to thrive in today’s competitive market.

The Growing Demand for Plastic Recycling in Nigeria

Nigeria generates millions of tons of plastic waste every year. The government, NGOs, and private companies are actively promoting recycling initiatives. This creates a golden opportunity for businesses to invest in recycling technology like the Plastic Granulator in Nigeria.

By investing now, companies can:

- Reduce operational costs.

- Strengthen brand reputation by supporting sustainability.

- Tap into Nigeria’s growing circular economy.

Why Choose Invoit Plast Machinery?

Invoit Plast Machinery is not just a Plastic Granulator Machine Manufacturer Nigeria; we are your long-term partner in industrial recycling success.

Here’s why we are the best choice:

- Experience: Decades of expertise in manufacturing high-performance granulators.

- Innovation: Constant upgrades to meet the latest industry standards.

- Trustworthiness: Hundreds of satisfied global clients, now serving Nigerian industries.

- Comprehensive Support: From machine selection to after-sales service, we provide end-to-end solutions.

When you choose Invoit Plast, you’re not only investing in an Affordable Plastic Granulator Nigeria but also securing reliable performance, support, and results.

FAQs

A Plastic Granulator Machine is industrial equipment designed to break down plastic waste into smaller granules or flakes. These granules can then be reused in production lines such as extrusion, molding, or recycling plants. Unlike shredders, which cut materials into rough pieces, granulators produce uniform-sized granules suitable for direct reprocessing.

Nigeria faces a major challenge with plastic waste management. A Plastic Granulator Machine helps recycling companies, manufacturers, and packaging industries convert waste into reusable raw materials. This reduces plastic pollution, cuts down production costs, and supports Nigeria’s circular economy goals.

Invoit Plast Machinery offers three main types:

- Slow Speed Granulators – For small-scale operations and near-machine recycling.

- Medium Duty Granulators – For medium-sized factories and recycling plants.

- Heavy Duty Granulators – For large-scale recycling industries handling high volumes of waste.

Industries that commonly use granulators include:

- Recycling plants

- Packaging companies

- Construction materials producers

- Automotive parts manufacturers

- Agricultural plastic recycling (e.g., irrigation pipes, greenhouse films)

- Reduces raw material costs by reusing plastics

- Promotes environmental sustainability

- Increases production efficiency

- Suitable for multiple types of plastic waste (PET, HDPE, LDPE, PVC, PP)

- Helps businesses comply with Nigeria’s environmental policies

Consider these factors before buying:

- Type of plastic waste you process

- Required production capacity

- Speed (slow, medium, or heavy-duty)

- Energy efficiency of the machine

- After-sales support and spare parts availability

A shredder cuts plastic waste into larger, uneven pieces, while a granulator reduces plastic into smaller, uniform granules. Granules are more suitable for direct reprocessing in molding, extrusion, or recycling systems.

Prices vary depending on capacity, size, and features. However, Invoit Plast Machinery provides affordable Plastic Granulator Machines in Nigeria that balance cost-effectiveness with durability, ensuring long-term value for businesses.

Yes, granulators can process a wide range of plastics including bottles, containers, films, pipes, sheets, and even tough materials like drums and thick pipes. The choice of machine depends on the type and volume of waste.

As a trusted Plastic Granulator Machine Manufacturer and Supplier in Nigeria, Invoit Plast offers:

- Proven expertise and innovation

- Durable, high-performance machines

- Technical support, installation, and training

- After-sales service and spare parts availability

- Affordable pricing without compromising quality