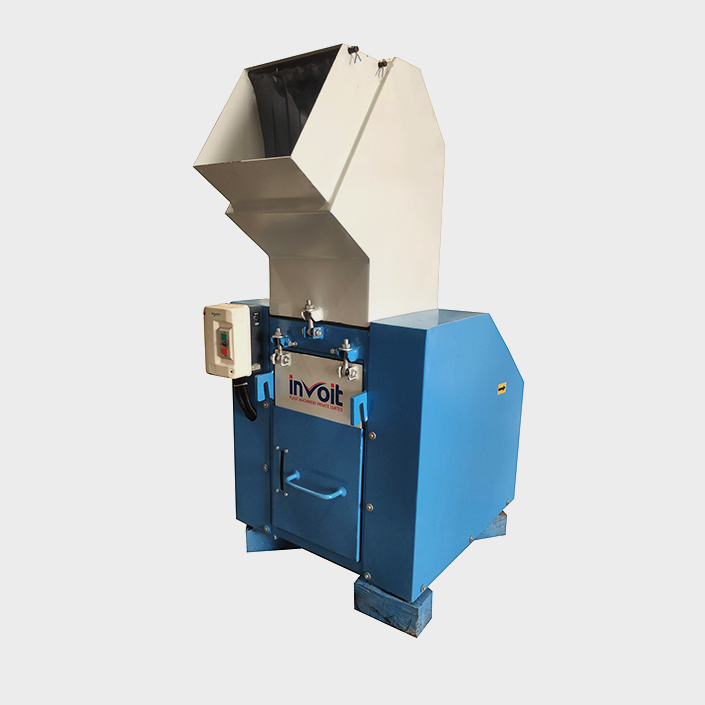

Plastic Granulator Machine

Plastic Granulator Machine

In today’s fast-paced plastic manufacturing world, efficiency, sustainability, and material recovery are more crucial than ever. Whether you’re operating an injection molding unit, a recycling plant, or a film production facility, managing plastic waste effectively is key to optimizing operations and cutting costs.

This essential piece of equipment transforms scrap plastic into uniform, reusable granules—reducing material waste, improving productivity, and enabling closed-loop manufacturing. From PET bottles and HDPE pipes to soft films and molded components, granulators help industries recycle internally and reduce reliance on virgin plastic.

At the forefront of this transformation is Invoit Plast Machinery Pvt. Ltd., a trusted name among plastic machinery manufacturers. Based in Ahmedabad, India, Invoit Plast is known for delivering high-quality, durable, and innovative granulator solutions that meet the needs of both local and global markets.

What is a Plastic Granulator Machine?

A plastic granulator machine is an industrial device designed to break down larger plastic components into smaller granules or flakes, which can then be reused in manufacturing.

How Does It Work?

The granulation process is relatively straightforward but mechanically robust:

- Feeding: Scrap plastic is loaded into the machine’s hopper.

- Cutting Mechanism: Inside, a series of rotary blades spin against stationary fixed blades, shearing the plastic into smaller pieces.

- Screening: Granules pass through a screen that ensures only material of the desired size is discharged.

- Collection: Finished granules are collected at the output chute or in a collection bin for reuse.

This process is essential in recycling applications, helping manufacturers reprocess plastic efficiently without compromising on quality.

Role in Sustainability

Granulators reduce plastic waste, support circular production models, and lower raw material expenses. In an industry increasingly focused on eco-friendly manufacturing, they play a vital role in meeting both environmental and economic goals.

Types of Plastic Granulator Machines

Every plastic application is different—so choosing the right type of granulator is critical. At Invoit Plast, we offer a full range of machines tailored to your material type, throughput needs, and operational scale.

Slow-Speed Granulators

- Best for: Sprues, runners, and fragile or brittle plastics

- Speed: Operates at low RPMs

- Advantages:

- Low noise levels

- Less dust generation

- Reduced wear and tear

These are ideal for beside-the-press applications where immediate recycling is desired with minimal noise.

Medium-Duty Granulators

- Best for: General-purpose plastics, molded parts, profiles

- Speed: Moderate RPMs with balanced throughput

- Advantages:

- Versatile and economical

- Compact footprint

- Suitable for small to mid-scale operations

Invoit Plast is a reputed medium-duty granulator machine manufacturer in India, offering machines that are perfect for day-to-day production waste management.

Heavy-Duty Granulators

- Best for: Thick sheets, large components, drums, automotive parts

- Speed: High-powered motors with high RPMs

- Advantages:

- Handles tough and rigid materials

- High output capacity

- Durable under heavy loads

Our heavy-duty plastic granulators are built to tackle even the most demanding industrial jobs—ensuring uninterrupted performance.

Key Features of High-Performance Plastic Granulators

When investing in a granulator, performance, safety, and ease of operation are paramount. Invoit Plast machines are engineered to offer all this and more.

Industrial-Grade Build Quality

- Rigid steel frame

- Vibration-free base

- Long-lasting wear resistance

Precision-Engineered Blades

- Hardened rotary and fixed blades

- Sharp cutting edges for clean, consistent granulation

- Easy to remove and sharpen

Safety & Noise Reduction

- Integrated safety interlocks

- Emergency shutoff mechanisms

- Optional noise insulation for quieter operation

Energy Efficiency

- High-efficiency motors

- Low power consumption per kg of output

- Optimized rotor design for better airflow and cooling

Smart Drive Systems

- Heavy-duty gearboxes

- Thermal overload protection

- Variable frequency drives (VFD) for speed control

Custom Hopper & Screen Options

- Adjustable hopper sizes

- Interchangeable screen meshes (3mm to 12mm and beyond)

- Designed to handle specific shapes and material flows

Applications Across Plastic Industries

Plastic granulators aren’t limited to recycling plants—they’re used across nearly every plastic production segment.

Industries that benefit from plastic granulators include:

- Film and Sheet Plants: Trim waste, start-up rolls, and off-spec films

- Blow Molding Units: Scrap bottles, containers, and parisons

- Injection Molding Operations: Runners, sprues, and rejected parts

- Plastic Recycling Facilities: Sorting, shredding, and granulating post-consumer waste

- Pipe and Profile Manufacturers: Excess lengths, damaged pipes, and end-of-line scraps

Whether you’re processing rigid PVC pipes or soft LDPE films, a granulator machine helps close the loop.

How to Choose the Right Plastic Granulator Machine

Choosing the right machine can significantly impact productivity and ROI. Here’s a quick checklist to guide your decision:

Type of Plastic

- Soft films: Require low-speed or tangential granulators

- Hard thermoplastics: Prefer heavy-duty models with robust blades

Output Requirements

- Estimate your daily or hourly throughput needs

- Match granulator motor power and screen size accordingly

Facility Layout

- Estimate your daily or hourly throughput needs

- Match granulator motor power and screen size accordingly

Blade Configuration

- Number of blades (3, 5, or 7)

- Open vs. closed rotor types

- Blade angle and alignment

Budget & ROI

- Consider long-term value over short-term cost

- Energy savings, reduced downtime, and lower maintenance all add up

Support and Service

- Local support means faster response

- Choose a granulator machine supplier in Ahmedabad with reliable after-sales service—like Invoit Plast.

Why Invoit Plast Machinery Pvt. Ltd. is the Best Choice in India

At Invoit Plast, we don’t just build machines—we build partnerships.

As a leading plastic granulator machine manufacturer in India, we bring decades of engineering expertise, customer-focused solutions, and consistent innovation to your production floor.

Why Customers Trust Invoit Plast:

- Located in Ahmedabad – India’s plastic machinery hub

- Premium components: Motors, blades, gearboxes

- Tailor-made solutions for your unique application

- On-time delivery & expert installation

- Global-ready machines meeting CE & export standards

- Dedicated after-sales support across India and abroad

Whether you’re looking for a plastic granules making machine, an industrial plastic crusher and granulator, or a custom-built solution—we’ve got you covered.

Maintenance Tips for Long-Lasting Performance

To keep your plastic waste granulator running like new, follow these best practices:

Specification

| Sr. No. | Models | Disc. Dia | Main Motor | Output (Kg./hr) | Floor Space (mm) | Vibro inch | Pump (HP) | ||

| Length | Width | Height | |||||||

| 1 | PK-50 | 250 | 15 | 45-55 | 2000 | 1400 | 3000 | 26” | 0.5 |

| 2 | PK-80 | 300 | 20 | 60-80 | 2100 | 1400 | 3100 | 26” | 0.5 |

| 3 | PK-110 | 300 | 30 | 110-115 | 2100 | 1400 | 3100 | 32” | 0.5 |

| 4 | PK-160 | 400 | 40 | 155-170 | 2400 | 1600 | 3500 | 39” | 0.5 |

| 5 | PK-200 | 400 | 50 | 185-220 | 2400 | 1600 | 3500 | 48” | 1.0 |

| 6 | PK-250 | 600 | 60 | 240-260 | 3500 | 1850 | 4000 | 48” | 1.0 |

| 7 | PK-300 | 600 | 75 | 300-325 | 3500 | 1850 | 4000 | 60” | 1.0 |

At Invoit Plast, we don’t just build machines—we build partnerships.

As a leading plastic granulator machine manufacturer in India, we bring decades of engineering expertise, customer-focused solutions, and consistent innovation to your production floor.

Routine Maintenance Checklist:

- Blade Care: Sharpen or replace blades regularly to avoid inefficient cutting

- Hopper & Screen Cleaning: Prevent material buildup and ensure smooth flow

- Motor Monitoring: Watch for abnormal sounds, overheating, or vibration

- Lubrication: Keep bearings and moving parts well-lubricated

- Electrical Checks: Periodically inspect wiring, switches, and controls

Proactive maintenance minimizes unplanned downtime and extends machine lifespan significantly.