Nigeria’s Pipe, Sheet, & Injection Molding Industries: Get Direct Pricing from Plastic Granulator Machine Suppliers

The plastics manufacturing sector in Nigeria is undergoing rapid transformation. With rising demand for products like plastic pipes, sheets, containers, and injection-molded components, industries are increasingly focusing on efficient recycling and material reuse. At the heart of this shift lies one critical piece of equipment — the Plastic Granulator Machine.

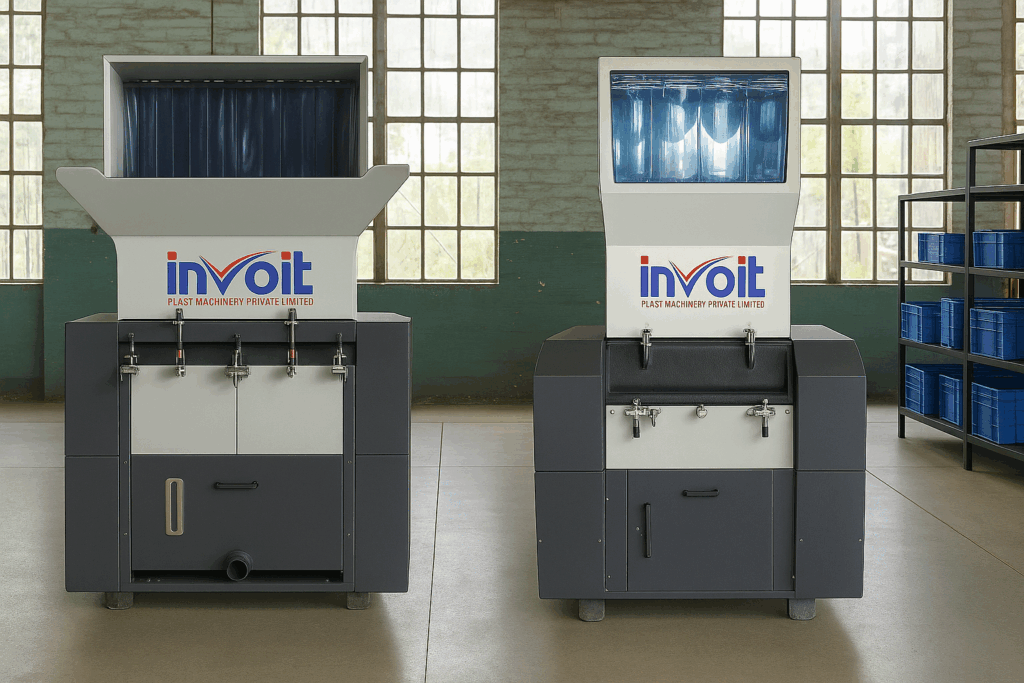

For manufacturers looking to reduce raw material costs, optimize production, and improve sustainability, finding the right Plastic Granulator Machine in Nigeria is essential. Leading the way in this transformation is Invoitplast Machinery — the Best Plastic Granulator Machine Manufacturer & Supplier in Nigeria, offering reliable, energy-efficient, and durable recycling solutions designed for the specific needs of the Nigerian plastics industry.

The Growing Demand for Plastic Recycling in Nigeria

Nigeria’s industrial growth and urban development have significantly increased the use of plastic products in packaging, construction, and manufacturing. As a result, there’s a parallel rise in plastic waste generation, prompting industries to adopt Plastic Recycling Machines and Industrial Plastic Granulators to manage this efficiently.

Today, manufacturers in Lagos, Ibadan, Kano, and Port Harcourt are realizing that recycled plastic materials can drastically reduce production costs while supporting sustainability goals. Whether it’s LDPE films, HDPE pipes, or PP injection-molded parts, recycled granules produced through a Plastic Granulator Machine are proving invaluable for keeping the production cycle circular.

By integrating advanced recycling machinery, businesses are not only meeting local environmental regulations but also positioning themselves as forward-thinking, eco-friendly manufacturers.

Why Plastic Granulator Machines Are Vital in Nigeria’s Plastic Industry

A Plastic Granulator Machine plays a crucial role in breaking down scrap or rejected plastic parts into uniform granules that can be easily reused in the production process. It’s an essential step in creating a cost-efficient recycling loop for any plastic-based manufacturing operation.

In Nigeria’s pipe, sheet, and injection molding sectors, granulators are indispensable because they:

- Help recover and reuse post-production scrap

- Improve material efficiency and lower waste

- Enhance the quality of reprocessed plastic materials

- Reduce dependence on expensive virgin polymers

- Contribute to sustainable and circular production

From small-scale recyclers to large industrial processors, the Plastic Crusher Machine and Industrial Plastic Granulator are now considered fundamental investments for productivity and cost management.

How Different Industries in Nigeria Benefit from Plastic Granulators

Plastic Pipe Manufacturing

The PVC and HDPE pipe industry in Nigeria is one of the fastest-growing markets, fueled by infrastructure and construction projects. Manufacturers often deal with rejected or off-spec pipes during extrusion. Instead of discarding them, they can be reprocessed using a Plastic Granulator Machine, reducing waste and cost simultaneously.

These granules are then mixed with virgin material to maintain product strength, offering a perfect balance between quality and cost savings.

Plastic Sheet and Film Production

Film and sheet producers working with LDPE and LLDPE materials often have leftover trims and roll ends. With a Plastic Recycling Machine in Nigeria, they can convert these production wastes into reusable granules.

By reusing these recycled pellets, companies minimize material wastage, improve profitability, and contribute to sustainable operations — all while maintaining film clarity and tensile strength.

Injection Molding and Component Manufacturing

Injection molding companies in Nigeria face constant material loss during start-ups, mold changeovers, or defective runs. A Plastic Granulator Machine helps reclaim these parts efficiently, grinding them into consistent regrind material that can be directly fed back into the molding process.

This reduces raw material purchase frequency and ensures better process control — key for maintaining profitability in a competitive manufacturing environment.

Choosing the Right Plastic Granulator Machine for Nigerian Industries

When selecting a Plastic Granulator Machine Manufacturer in Nigeria, it’s important to consider several technical and operational factors to ensure long-term reliability and optimal performance.

Here are some critical aspects to evaluate before investing:

- Material Type: The granulator design should match the specific materials being processed — whether soft LDPE film, rigid PVC pipes, or PP components.

- Motor Power & Blade Configuration: Ensure the machine offers the right combination of cutting blades, torque, and speed for your application.

- Output Capacity: Choose a machine with throughput capacity that aligns with your production volume.

- Ease of Maintenance: Machines with accessible cutting chambers and replaceable blades save valuable downtime.

- Energy Efficiency: Modern granulators designed with optimized motors and smart controls reduce operational costs.

- Safety Features: Proper guarding, emergency stop systems, and safety interlocks ensure secure operation in industrial environments.

By carefully matching these parameters, manufacturers can achieve a perfect balance between Plastic Granulator Machine Price, performance, and reliability.

Why Invoitplast Machinery Leads as a Plastic Granulator Machine Manufacturer in Nigeria

Invoitplast Machinery has built a strong global reputation for manufacturing high-performance Plastic Granulator Machines and Plastic Recycling Machines engineered for efficiency, durability, and low maintenance.

With a focus on innovation and quality, Invoitplast machines are designed to handle the diverse needs of Nigeria’s pipe, film, and molding industries.

Here’s why Nigerian manufacturers prefer Invoitplast:

- Customized Solutions: Each granulator is designed to meet specific material and capacity requirements.

- Heavy-Duty Construction: Machines are made with robust steel frames and hardened cutting blades to ensure longevity.

- Energy-Efficient Design: Optimized motors and cutting chambers reduce power consumption while improving throughput.

- Consistent Output: Precision-engineered blades ensure uniform granule size for reprocessing.

- Reliable After-Sales Support: Invoitplast provides installation guidance, technical assistance, and spare parts support.

Whether you operate a small-scale recycling setup or a large extrusion plant, Invoitplast Machinery — the Best Plastic Granulator Machine Manufacturer & Supplier in Nigeria — delivers machines that combine performance, durability, and affordability.

Enhancing Plastic Recycling Efficiency in Nigeria with Industrial Plastic Granulators

Nigeria’s industrial ecosystem is becoming increasingly conscious of recycling efficiency. An Industrial Plastic Granulator is not just a cost-saving machine — it’s an enabler of sustainability and productivity.

The machine’s sharp rotary and stationary blades ensure uniform particle size, which enhances melt consistency during re-extrusion or molding. This consistency results in better-quality final products and reduced processing defects.

Moreover, when used in combination with a Plastic Recycling Machine, businesses can establish a closed-loop recycling system — where every rejected or scrap material is converted back into usable raw form.

This approach has become crucial for companies aiming to:

- Minimize production costs

- Comply with environmental standards

- Strengthen their brand image through sustainability

- Improve operational efficiency

Understanding Plastic Granulator Machine Price in Nigeria

While it’s tempting to look only at the Plastic Granulator Machine Price, professionals in the industry understand that total lifecycle value is far more important than the initial cost.

Investing in a high-quality machine reduces long-term expenses by minimizing breakdowns, lowering maintenance frequency, and ensuring consistent granule output. Machines from trusted brands like Invoitplast Machinery offer superior performance, making them a smarter investment choice for serious manufacturers.

Buyers are encouraged to connect directly with reputable suppliers to get customized quotations based on production capacity, application type, and technical requirements — ensuring the best return on investment without revealing direct pricing publicly.

The Future of Plastic Recycling Machine Use in Nigeria

As sustainability becomes a key priority for manufacturers across Africa, the demand for Plastic Recycling Machines in Nigeria is set to rise exponentially. Companies are increasingly looking for ways to close the production loop — from waste generation to raw material regeneration.

This shift opens vast opportunities for manufacturers who integrate recycling machinery into their operations early. By doing so, they can:

- Gain a competitive edge through cost efficiency

- Align with Nigeria’s waste management and recycling policies

- Meet the growing consumer demand for eco-friendly plastic products

In this evolving landscape, Plastic Granulator Machines, Plastic Crusher Machines, and other recycling solutions will remain central to industrial success.

Final Thoughts

The future of Nigeria’s pipe, sheet, and injection molding industries is deeply tied to how effectively they manage and reuse plastic waste. By investing in reliable, high-performance Plastic Granulator Machines and Plastic Recycling Machines, manufacturers can achieve both economic and environmental gains.

For businesses ready to enhance recycling efficiency and production quality, Invoitplast Machinery — the Best Plastic Granulator Machine Manufacturer & Supplier in Nigeria — stands as a trusted partner. Their advanced, energy-efficient granulators are designed to meet the toughest industrial demands, helping you stay competitive in Nigeria’s fast-growing plastics market.

Choosing the right granulator isn’t just about cost — it’s about performance, sustainability, and long-term value. With Invoitplast Machinery, you’re investing in equipment that powers the future of plastic recycling in Nigeria.

FAQs

A Plastic Granulator Machine is used to break down plastic waste, defective products, and scrap materials into small, uniform granules. These granules can be reused in the production of new plastic items, helping manufacturers reduce raw material costs and improve recycling efficiency.

In Nigeria, industries like pipe extrusion, film production, and injection molding use granulators to recycle post-production waste. The machine reduces plastic scrap into reusable material, improving sustainability, cutting down waste disposal costs, and supporting circular manufacturing practices.

A Plastic Crusher Machine performs initial size reduction by crushing large plastic parts into smaller pieces, while a Plastic Granulator Machine further processes these pieces into fine, uniform granules ready for reprocessing. Many manufacturers use both machines together for complete recycling efficiency.

The Plastic Granulator Machine Price in Nigeria depends on several factors such as machine capacity, motor power, blade design, material type, and level of automation. While price is important, industries focus more on performance, energy efficiency, and long-term reliability when choosing equipment.

Invoitplast Machinery is widely recognized as the Best Plastic Granulator Machine Manufacturer & Supplier in Nigeria, offering advanced, energy-efficient, and durable granulators for the pipe, sheet, and injection molding industries. Their machines are built to deliver consistent output and high performance under demanding industrial conditions.

Yes, combining a Plastic Granulator Machine with a Plastic Recycling Machine allows industries to establish a closed-loop recycling system. The granulator converts waste into granules, while the recycling machine reprocesses them into usable plastic material for manufacturing new products.

Plastic recycling helps Nigerian industries lower material costs, reduce environmental impact, and comply with government sustainability initiatives. It also supports local manufacturing growth by creating a reliable supply of recycled raw materials, essential for cost-effective production.

Absolutely. Invoitplast Machinery supplies high-performance Plastic Granulator Machines and Plastic Recycling Machines across major Nigerian cities including Lagos, Ibadan, Kano, and Port Harcourt. Their technical support and service network ensure reliable performance and long-term value for every client.

To get the right machine, evaluate your material type (LDPE, HDPE, PVC, PP, etc.), output capacity, and energy requirements. Consult with trusted suppliers like Invoitplast Machinery to receive expert recommendations and direct pricing based on your production goals — without hidden costs or over-specification.

Yes, Invoitplast designs each Industrial Plastic Granulator with optimized cutting systems and energy-efficient motors. This ensures maximum productivity with minimal power consumption, making them ideal for continuous recycling operations in Nigeria’s industrial environments.