PVC Pulverizer Machine

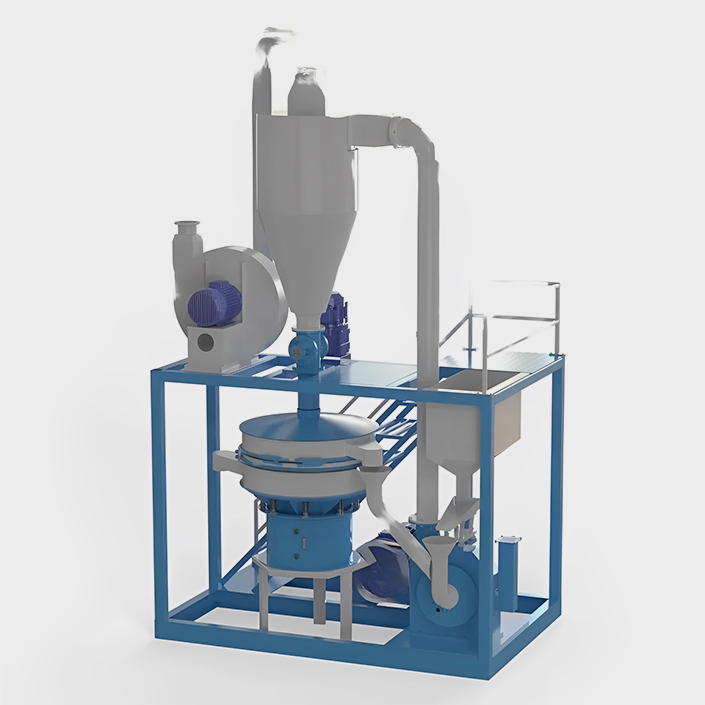

PVC Pulveriser Machine

When it comes to turning PVC scraps into reusable powder, the PVC Pulveriser Machine plays a vital role in the plastic recycling and manufacturing industry. Whether you’re a plant manager, procurement officer, or industrial buyer, investing in the right pulveriser can significantly improve productivity, reduce material waste, and lower overall production costs.

Invoit Plast Machinery Pvt. Ltd., a leading PVC Pulveriser Machine manufacturer in India, offers high-performance, reliable machines that are engineered for Indian operating conditions. With a strong reputation in the plastic machinery market, Invoit Plast delivers value with every machine it builds.

About Invoit Plast Machinery Pvt. Ltd.

Invoit Plast Machinery Pvt. Ltd. is one of the most trusted names in the Indian plastic machinery manufacturing sector. Based in Ahmedabad, Gujarat, the company has years of experience delivering top-quality machines to clients across India and overseas.

Why choose Invoit Plast?

- Over a decade of industry experience

- Specialization in plastic recycling and processing machines

- ISO-certified manufacturing and testing processes

- Trusted by leading plastic product manufacturers and recyclers

- PAN India delivery and prompt support services

As a dependable PVC Pulveriser Machine manufacturer in India, Invoit Plast is committed to continuous improvement, innovation, and long-term client partnerships.

What is a PVC Pulveriser Machine?

A PVC Pulveriser Machine is a mechanical grinder designed to convert PVC scraps, pipes, and regrind into fine powder. This powder can be reused in the production of PVC profiles, pipes, cables, sheets, and other plastic products.

How it works:

The machine operates using a high-speed rotating disc and fixed grinding segments. PVC material is fed into the hopper, ground between the discs, and collected as powder in the output collection unit. It is energy-efficient, high-speed, and built to run continuously in industrial environments.

Materials it handles:

- Rigid PVC

- Soft PVC

- PVC regrind from pipes, profiles, cables, etc.

- Plastic scraps and off-cuts

Who uses it?

- Plastic recycling units

- PVC pipe manufacturers

- Sheet and profile manufacturers

- Cable and conduit producers

- Compounding and masterbatch units

Whether you’re running a mid-sized plant or a large-scale production unit, a PVC Pulveriser Machine in India from Invoit Plast can boost your efficiency.

Applications & Use Cases

The PVC Pulveriser Machine is widely used across multiple segments of the plastic processing industry. It supports sustainable practices by enabling the reuse of PVC waste.

Key industries served:

- Plastic recycling plants

- PVC pipe and fitting manufacturers

- Profile extrusion units

- Electrical cable and conduit factories

- Plastic sheet and thermoforming plants

Benefits of using a PVC Pulveriser Machine:

- Reduces raw material costs by recycling in-house scrap

- Produces fine PVC powder suitable for reprocessing

- Increases operational efficiency

- Supports environmental compliance and zero-waste goals

Common use cases:

- Regrinding leftover PVC pipe scrap for reuse

- Pulverising rejected profiles and trimmings

- Preparing PVC powder for compounding or mixing

- Supporting downstream production with consistent feedstock

Why Choose Invoit Plast as Your PVC Pulveriser Machine Manufacturer in India

At Invoit Plast, every machine is built with precision, care, and customer needs in mind. Here’s what sets us apart:

Superior product quality:

- Sturdy build with high-grade steel components

- Vibration-free and low-noise design

- Long-lasting grinding discs with high wear resistance

Tailored solutions:

- Custom machine sizes and capacities

- Adjustable output particle size

- Modular design for easy upgrades

Customer-first support:

- On-site installation and commissioning

- Hands-on training for operators

- Quick spare parts availability

- Dedicated customer service team

We don’t just sell machines—we build long-term relationships by helping clients succeed with every machine they buy.

Maintenance & Operating Tips for Better Machine Life

Taking care of your PVC Pulveriser Machine ensures better performance and a longer lifespan. Here are some practical tips to keep your machine running smoothly:

Daily maintenance practices:

- Clean the hopper, grinding chamber, and filter daily

- Check for any unusual noise or vibration

- Ensure all fasteners and belts are tightened

Boost durability and efficiency:

- Use the recommended feed material size

- Avoid overloading the machine

- Schedule regular checks for blade wear and motor performance

Troubleshooting tips:

- Low output? Check for worn grinding segments

- Overheating? Clean filters and inspect ventilation

- Vibration? Re-balance the rotor or check foundation bolts

Following these steps will help you get the most out of your investment.

Cost & Investment Guide: What to Expect When Buying a PVC Pulveriser Machine

Investing in a PVC Pulveriser Machine in India is a smart decision for manufacturers and recyclers. Here’s what you should consider:

Factors affecting cost:

- Machine capacity (in kg/hr)

- Motor power and type (standard vs. energy-efficient)

- Type of material used in construction

- Automation features and add-ons

Return on Investment (ROI):

- Savings on virgin PVC material

- Faster recycling and reduced downtime

- Improved product consistency and quality

Choosing the right model:

- For small to mid-sized plants: 100–200 kg/hr models

- For large-scale factories: 300–600 kg/hr models

- Consider energy use, footprint, and production volume

Our team at Invoit Plast is happy to guide you based on your specific plant requirements and budget.