PVC Pulverizer Machine: Your Ultimate Manufacturer & Supplier Guide for High-Efficiency Recycling

In today’s fast-growing plastic recycling and processing industry, PVC Pulverizer Machines have become indispensable for achieving precision, consistency, and high output during the material regrinding process. Whether you’re recycling rigid PVC pipes, profiles, or soft PVC films, a reliable pulverizer ensures uniform powder quality — crucial for efficient downstream processing like extrusion, molding, or compounding.

If you’re a plastic recycler, processor, or manufacturer looking for the best pulverizing equipment, this guide will help you understand how PVC Pulverizer Machines work, what to look for in a reliable PVC Pulverizer Machine Manufacturer in India, and why investing in a high-quality system can drastically improve your productivity and profitability.

Understanding the Role of a PVC Pulverizer Machine in Recycling

A PVC Pulverizer Machine is designed to grind and pulverize plastic scrap or virgin material into fine powder. This powder is then reused in manufacturing plastic products, thereby promoting circular economy and reducing production costs.

The pulverization process involves mechanical grinding using high-speed rotating discs or blades that break down PVC granules into fine particles. This fine PVC powder is ideal for reprocessing into films, pipes, cables, and profiles.

Compared to conventional milling systems, a Plastic Pulverizer Machine offers higher throughput, consistent particle size, and lower energy consumption, making it an ideal choice for large-scale recycling plants and compounding units.

Why PVC Pulverizer Machines Are Essential for Modern Plastic Recycling

PVC, or Polyvinyl Chloride, is widely used in packaging films, profiles, cables, and pipes due to its excellent chemical resistance and durability. However, recycling PVC requires specialized equipment because of its thermal sensitivity and need for precise grinding control.

A PVC Pulverizer Machine India setup ensures:

- Uniform Powder Quality: Delivers consistent fineness essential for reprocessing.

- Energy Efficiency: Uses optimized motor and blade designs for reduced power consumption.

- High Productivity: Capable of processing large volumes with minimal downtime.

- Thermal Stability: Advanced cooling systems prevent overheating and material degradation.

- Reduced Waste: Converts rejected or off-spec material into reusable powder, cutting down wastage.

These features make the pulverizer a critical link in any plastic recycling machine setup, especially for manufacturers producing PVC-based products.

Key Components and Working Principle

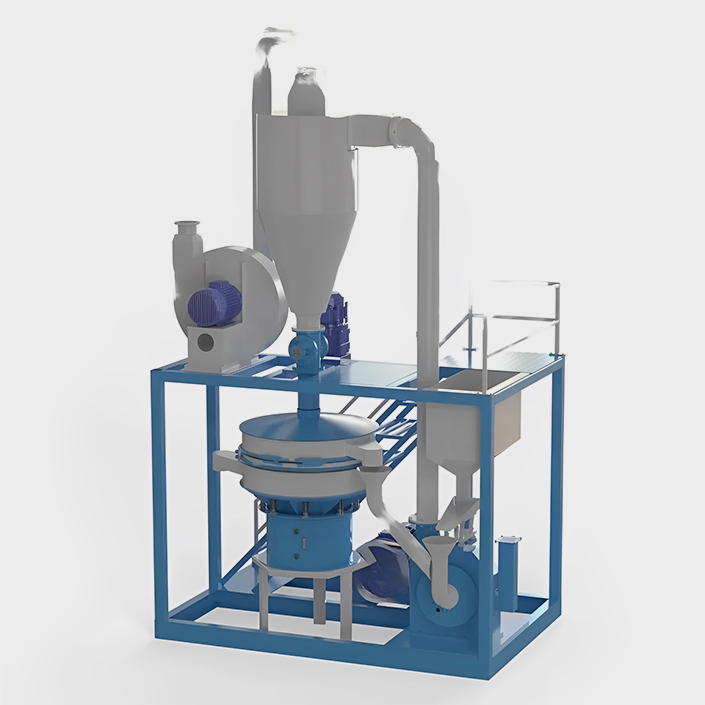

A typical PVC Pulverizer Machine comprises several precision-engineered parts that work together to achieve fine and uniform powdering.

Feeding System

PVC granules or scraps are uniformly fed into the machine through an automatic feeding system that ensures steady flow and prevents overloading.

Pulverizing Chamber

The heart of the system — where the material is ground by high-speed rotating discs or fixed blades. The design and sharpness of these discs directly affect output quality.

Vibratory Sieve

After pulverization, the powder passes through a vibratory screen that separates fine powder from coarse particles, ensuring consistent particle size distribution.

Cooling System

PVC is temperature-sensitive. Efficient air or water-cooled systems maintain optimal operating temperatures to avoid material degradation.

Collection Unit

Finally, the processed powder is collected in storage bins or bags, ready for further processing or packaging.

Selecting the Right PVC Pulverizer Machine Manufacturer in India

Choosing the right PVC Pulverizer Machine Manufacturer India can be the difference between smooth operations and frequent maintenance downtime. Here’s what you should look for:

Proven Engineering Expertise

Select manufacturers with a solid track record in designing Plastic Pulverizer Machines optimized for various PVC applications. The manufacturer’s experience directly impacts the reliability and precision of the equipment.

Customization Options

Every recycling setup is different. A trusted supplier should offer customized solutions in terms of capacity, blade design, and cooling mechanisms based on your production requirements.

Quality Materials & Precision Manufacturing

Machines built with high-grade steel and CNC-machined components ensure longer lifespan and superior grinding performance.

After-Sales Support & Spares Availability

Look for manufacturers who provide strong technical support, quick availability of spare parts, and on-site service to minimize downtime.

Compliance & Safety Standards

Ensure the equipment complies with international standards for safety, performance, and energy efficiency.

InvoitPlast Machinery — Best PVC Pulverizer Machine Manufacturer & Supplier in India

When it comes to reliability, precision, and efficiency, InvoitPlast Machinery Pvt. Ltd. stands out as one of the best PVC Pulverizer Machine Manufacturers and Suppliers in India.

With years of engineering excellence in plastic recycling machine, InvoitPlast offers state-of-the-art PVC Pulverizer Machines designed for both small-scale and large industrial operations.

Their pulverizers are known for:

- High-Speed Pulverization with Uniform Output

- High-Speed Pulverization with Uniform Output

- Advanced Cooling Mechanisms to Prevent PVC Degradation

- User-Friendly Control Systems for Ease of Operation

- Durable Blades and Low Maintenance Requirements

Whether you deal in PVC pipes, profiles, films, or cables, InvoitPlast provides the right solution tailored to your production goals — helping you optimize your recycling efficiency and maximize returns.

Benefits of Investing in a High-Performance PVC Pulverizer

Modern PVC Pulverizer Machines India are built to deliver performance, efficiency, and consistency across long production runs. Investing in a high-quality pulverizer yields multiple advantages:

Enhanced Production Efficiency

High-speed blades and efficient feeding systems ensure continuous processing with minimal operator intervention.

Consistent Powder Quality

Uniform granule-to-powder conversion means smoother extrusion and molding processes downstream.

Energy Savings

Smart motor designs and cooling systems reduce power usage, lowering your overall production costs.

Low Maintenance and Long Service Life

Durable materials, precision engineering, and easy-access parts reduce maintenance frequency and extend machine life.

Eco-Friendly Operations

By reusing waste PVC materials, your business supports a sustainable, circular manufacturing process — reducing landfill waste and conserving resources.

Applications of PVC Pulverizer Machines in Industry

PVC pulverizers find applications across several plastic manufacturing and recycling sectors. Common uses include:

- PVC Pipe Manufacturing: Grinding rejected pipes or trimmings for re-extrusion.

- Cable and Wire Industry: Reusing insulation materials efficiently.

- Film and Sheet Production: Pulverizing scrap films for reprocessing.

- Plastic Compounding: Producing consistent powder for blending and formulation.

- Masterbatch Production: Generating fine powder for pigment dispersion.

In each of these applications, using a high-performance Plastic Pulverizer Machine ensures steady material flow and consistent product quality.

How to Ensure Long-Term Performance of Your PVC Pulverizer Machine

Even the most advanced machine requires proper care and maintenance to perform at its best. Here are some best practices:

- Regular Blade Inspection: Check for wear and sharpness to maintain grinding quality.

- Monitor Temperature: Avoid excessive heat buildup to prevent PVC degradation.

- Clean the Chamber Frequently: Prevent material buildup that can affect efficiency.

- Lubricate Bearings and Moving Parts: Ensure smooth mechanical operation.

- Schedule Preventive Maintenance: Follow manufacturer-recommended service intervals.

By implementing these practices, you can extend the operational life of your PVC Pulverizer Machine and maintain consistent production quality.

Why Choose Indian Manufacturers for PVC Pulverizer Machines

India has emerged as a global hub for plastic recycling machinery thanks to advanced engineering capabilities, competitive pricing, and strong after-sales service networks.

Leading PVC Pulverizer Machine Manufacturers in India like InvoitPlast deliver world-class quality comparable to global brands, but with better adaptability to local conditions and technical support.

Moreover, with India’s growing emphasis on sustainability and recycling, investing in Indian-made pulverizers ensures long-term operational and environmental benefits.

Final Thoughts: Elevate Your Recycling Operations with InvoitPlast

A PVC Pulverizer Machine is more than just equipment — it’s a strategic investment that directly influences your product quality, production efficiency, and profitability.

By partnering with a trusted name like InvoitPlast Machinery Pvt. Ltd., you gain access to innovative design, reliable performance, and long-term service assurance. As one of the leading PVC Pulverizer Machine Manufacturers in India, InvoitPlast continues to set benchmarks for quality and innovation in plastic recycling technology.

If your goal is to enhance recycling output, improve powder consistency, and reduce energy consumption, then investing in a high-efficiency PVC Pulverizer Machine India solution from InvoitPlast is your best move toward a smarter, more sustainable production future.

FAQs

A PVC Pulverizer Machine is used to grind PVC scrap or granules into fine powder for reuse in manufacturing pipes, profiles, cables, and films.

While both machines serve similar functions, a PVC Pulverizer is designed specifically to handle the thermal sensitivity and hardness of PVC materials.

Yes, when processed correctly using a precision pulverizer, recycled PVC powder can achieve near-virgin quality suitable for many applications.

InvoitPlast Machinery Pvt. Ltd. is widely recognized as one of the best PVC Pulverizer Machine Manufacturers and Suppliers in India, offering durable, energy-efficient, and high-output machines.

Blade design, cooling efficiency, motor power, and material feeding consistency all play a major role in determining pulverizer performance.