PVC Pulverizer Machine for Plastic Recycling – Buy Direct from Manufacturer

In the evolving world of plastic recycling, manufacturers and suppliers are constantly seeking efficient machines to maximize output, maintain quality, and reduce material waste. One such critical machine in this process is the PVC Pulverizer Machine. This machine plays a vital role in transforming rigid PVC plastic scrap into fine powder form that can be reused in production. With the rise of circular economy practices, investing in a reliable and efficient PVC pulverizer is not just an operational decision, but also an environmental commitment.

If you’re looking to buy a PVC pulverizer machine, understanding its functions, advantages, and manufacturer credibility is crucial. This blog explores everything you need to know about PVC pulverizers – from how they work to why it’s best to buy directly from the manufacturer. And if you are sourcing from India, Invoit Plast Machinery PVT Ltd stands out as the Best PVC Pulverizer manufacturer in India.

What is a PVC Pulverizer Machine?

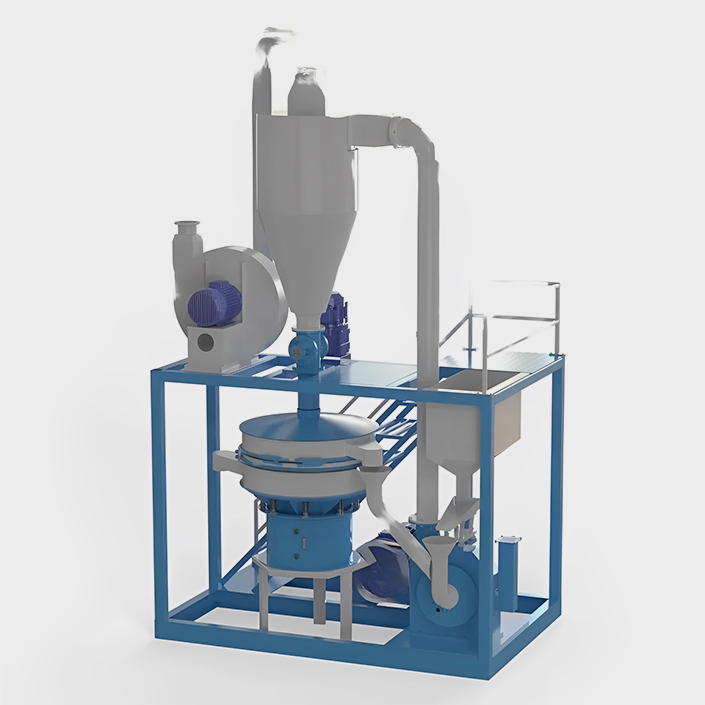

A PVC Pulverizer Machine is a type of Plastic Recycling Machine specifically designed to grind rigid PVC scraps, pipes, profiles, and sheets into fine powder. This powder is later used in manufacturing plastic products such as pipes, cable insulation, window profiles, and more. The machine operates at high speeds using disc-blade technology or segments, depending on the type, and ensures uniform particle size, minimal heat generation, and consistent throughput.

PVC pulverizers are available in different capacities and configurations based on the production needs of manufacturers. Whether you are in pipe production or profile extrusion, a well-calibrated PVC pulverizer machine ensures that plastic waste is not wasted but rather reintegrated into the manufacturing line.

Working Principle of PVC Pulverizer Machine

The pulverization process begins with feeding rigid PVC scrap into the machine’s hopper. A rotating disc or blade system breaks down the material through centrifugal force and high-speed impact. As the scrap enters the grinding chamber, it is finely ground until the required mesh size is achieved.

The built-in sieve or screen ensures only powder of the desired fineness passes through, while larger particles are recirculated for further grinding. An attached blower system helps collect the pulverized material, which is then stored in a cyclone separator or collection bin.

This closed-loop process ensures minimal dust, high output, and reduced heat generation, which is critical when dealing with PVC – a heat-sensitive polymer.

Applications of PVC Pulverizer in Plastic Recycling

PVC pulverizer machines are indispensable in a wide range of plastic recycling operations, especially for:

- Rigid PVC pipe and fitting manufacturers

- Window profile producers

- Plastic compounding units

- Masterbatch manufacturers

- Recycled granule producers

- Cable and conduit extrusion plants

These industries benefit from the cost-saving advantage of reusing their own in-house plastic waste and converting external scrap into usable raw materials, reducing dependency on virgin resin.

Key Benefits of Using a PVC Pulverizer Machine

- Cost-Effective Plastic Waste Management

PVC pulverizers help manufacturers reduce plastic waste by converting it into valuable powder. This lowers raw material costs and contributes to sustainable operations.

- Improved Material Reusability

Pulverized PVC powder can be blended with virgin material or used directly in many plastic applications without compromising quality.

- Consistent Output

Modern pulverizers offer uniform particle size, which ensures consistent flow and processing during downstream applications like extrusion or molding.

- Easy Maintenance and Durability

Advanced machines come with wear-resistant components and easy-access design for maintenance, reducing downtime and ensuring continuous operation.

- Environmentally Sustainable

By recycling plastic waste in-house, manufacturers contribute to a circular economy and minimize the environmental impact of plastic disposal.

Why Buy Direct from Manufacturer?

Buying a PVC Pulverizer Machine directly from the manufacturer offers several undeniable advantages. Let’s break them down:

Customized Solutions

When you buy from a manufacturer like Invoit Plast Machinery PVT Ltd, you gain the benefit of customization. Whether you need a specific capacity, blade configuration, or automation integration – the manufacturer can deliver exactly what suits your production line.

Competitive Pricing

Direct buying eliminates the middlemen, giving you access to factory prices. This helps businesses, especially startups or small units, to invest smartly without inflating budgets.

After-Sales Service and Support

Local manufacturers offer faster and more reliable after-sales support, including maintenance, spare parts availability, and technical assistance.

Faster Delivery & Installation

Domestic sourcing ensures shorter lead times and quick installation, which speeds up your production setup and return on investment.

Upgradation & Scalability

As your business grows, buying from a trusted manufacturer allows for easy upgrades or capacity enhancements through modular machines or compatible parts.

Why Choose Invoit Plast Machinery PVT Ltd?

When it comes to selecting a trustworthy PVC Pulverizer manufacturer in India, Invoit Plast Machinery PVT Ltd has earned a solid reputation. Based in Ahmedabad, Gujarat – a manufacturing hub for plastic machinery – Invoit Plast is known for engineering precision-built, high-performance plastic recycling solutions.

As the Best PVC Pulverizer manufacturer in India, Invoit Plast ensures:

- State-of-the-art machines with energy-efficient technology

- Premium-grade raw materials and components for durability

- Customization according to application requirements

- Nationwide and international service reach

- Technical consultation and training for machine operation

- Competitive pricing directly from the factory

The company’s commitment to quality, timely delivery, and customer support makes it a preferred partner among plastic product manufacturers and recyclers.

How to Select the Right PVC Pulverizer Machine

Choosing the right pulverizer can make a significant impact on your production quality and cost-efficiency. Here are some points to consider:

- Material Type: Know whether your recycling material is rigid PVC pipe, profile, sheet, or regrind.

- Output Requirement: Define the quantity of powder you need per hour to match machine capacity accordingly.

- Fineness Level: Based on application, choose the mesh size you require (commonly 300–500 microns).

- Motor Power & Energy Efficiency: Ensure the motor is strong enough to support continuous operation without excessive energy consumption.

- Cooling System: PVC is sensitive to heat; so look for machines with air or water cooling systems.

- Automation Features: Auto feeding, digital control panels, and dust filters help boost productivity and ease of use.

- Maintenance Accessibility: A good machine design should allow easy access to discs, bearings, and sieves for routine maintenance.

Consulting directly with manufacturers like Invoit Plast Machinery PVT Ltd can simplify the selection process and ensure your machine fits your exact needs.

The Role of PVC Pulverizer in the Future of Plastic Recycling

As environmental regulations grow tighter and businesses shift towards sustainable production, Plastic Recycling Machines like PVC Pulverizers will continue to be the backbone of eco-conscious manufacturing. Whether it’s to reduce plastic waste or to achieve cost savings through reusability, these machines will become even more critical in the years ahead.

Invoit Plast continues to innovate in this space, offering advanced solutions that align with industry goals for green production and material circularity.

Final Thoughts

Investing in a high-quality PVC Pulverizer Machine is a smart move for any manufacturer in the plastic recycling ecosystem. It offers operational efficiency, cost-saving benefits, and environmental sustainability – all while maintaining high product quality.

To ensure maximum ROI and long-term support, always buy your PVC Pulverizer directly from the manufacturer. With years of experience and a commitment to excellence, Invoit Plast Machinery PVT Ltd remains the Best PVC Pulverizer manufacturer in India, trusted by manufacturers across the country and beyond.

Whether you’re setting up a new recycling line or upgrading your existing one, Invoit Plast is your reliable partner for cutting-edge plastic recycling machines.

FAQs

PVC pulverizer machines grind rigid plastic waste into fine powder, enabling manufacturers to reuse PVC material in making new plastic products like pipes, profiles, and cables.

The cost of a PVC pulverizer machine in India typically ranges from ₹2.5 lakhs to ₹10 lakhs or more, depending on capacity, brand, motor power, and automation features.

Invoit Plast Machinery PVT Ltd is recognized as the best PVC pulverizer manufacturer in India, offering durable machines with high performance, customization, and excellent after-sales service.

Some PVC pulverizer models can process other thermoplastics like PE, PP, or EVA, but they must be configured accordingly. Always check material compatibility with the manufacturer.

Output capacities vary by model, typically ranging from 50 kg/hr to 600 kg/hr, based on motor size, blade design, and material input type.

PVC pulverizer machines can achieve fine powders ranging from 200 mesh to 500 mesh, depending on sieve design and grinding disc quality.

Yes, PVC is heat-sensitive. Most machines come with air or water cooling systems to maintain optimal temperature and prevent material degradation.

A granulator cuts plastic into flakes or small pieces, while a pulverizer grinds the material into powder. Pulverizers are ideal for reusing plastic in powder form.

Routine maintenance includes checking the blades/discs, cleaning dust filters, lubricating moving parts, and inspecting the motor and blower systems regularly.

Yes, pulverizers can be integrated with mixers, extruders, and granulators for a complete recycling or compounding setup.