The Role of Gyro Screens in Modern Industrial Processing

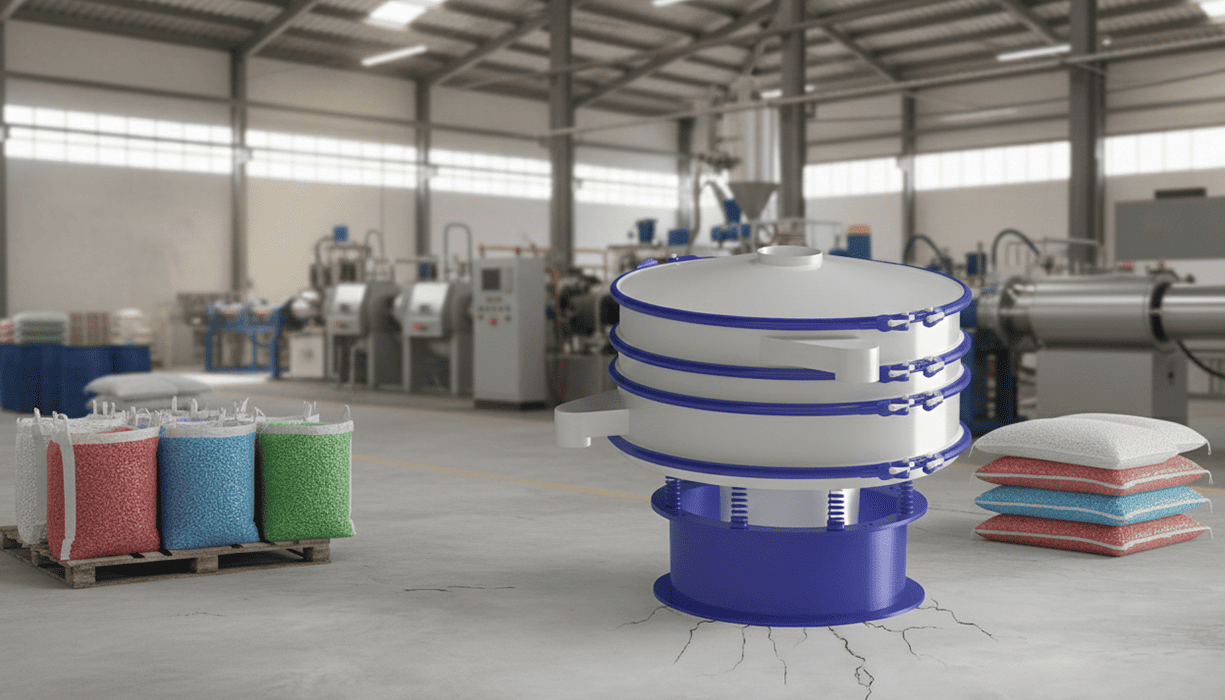

In today’s fast-paced manufacturing and processing industries, efficiency, precision, and consistency are critical to maintaining quality and reducing downtime. Among the many machines contributing to this level of productivity, Gyro Screens stand out as a highly versatile and essential equipment. Whether in the plastic, pharmaceutical, food, or chemical industries, Gyro Screens—also known as Vibro Sifters or circular separators—play a vital role in screening, grading, filtering, and separating materials.

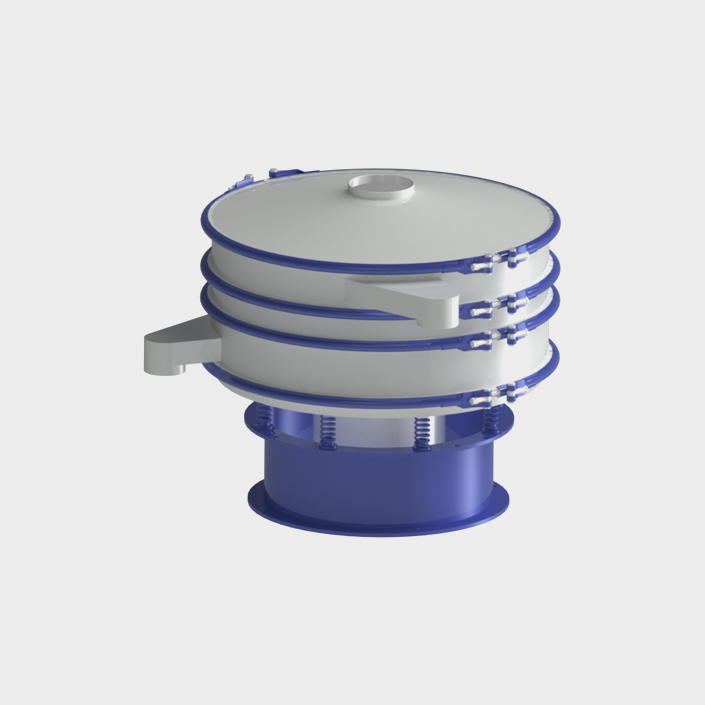

What is a Gyro Screen?

A Gyro Screen Machine is a high-performance vibratory screening unit used to separate solid particles or liquid slurries based on size. The machine utilizes a vibratory motor to generate multi-plane motion, enabling efficient separation of materials with different particle sizes. These machines are commonly used in the plastics, chemicals, food, ceramics, and minerals industries.

The core advantage of a Gyro Screen lies in its ability to deliver high-capacity screening with minimal downtime and maintenance, all while ensuring consistent output quality.

Why Are Gyro Screens Crucial in Modern Industrial Processing?

Industrial processing has grown more complex with advancements in materials and production technologies. Companies require reliable sieving and separation systems that can keep up with large-scale operations without compromising quality. Here’s how Gyro Screens are transforming modern processing environments:

Consistent Product Quality

One of the key roles of a Gyro Screen is to ensure product consistency by removing impurities and oversized or undersized particles. For example, in the plastic recycling industry, gyro screens help filter out contaminants from plastic granules or powder, ensuring only high-quality material moves forward in the process.

Whether it’s separating resins in a polymer plant or sieving powdered chemicals, a Gyro Screen for industrial use guarantees uniform particle size, directly impacting product quality.

Multi-Deck Screening Efficiency

Modern Gyro Screens are available with multiple decks, allowing users to perform several levels of grading in a single pass. Each deck is fitted with screens of different mesh sizes, enabling classification into various grades. This multi-layered approach reduces the need for secondary screening, saving energy and time.

Versatility Across Industries

The adaptability of Gyro Screen Machines makes them indispensable in a wide range of industries:

- Plastic Industry: For screening plastic granules, regrind, and powder.

- Food Processing: For separating flour, spices, sugar, and other ingredients.

- Chemical Industry: For classifying fine powders, dyes, and additives.

- Pharmaceuticals: For filtering active pharmaceutical ingredients (APIs) and excipients.

- Minerals and Metals: For grading sand, limestone, and metallic powders.

Dust-Free Operation and Hygiene

Modern gyro screens are equipped with sealed enclosures to prevent dust escape and contamination. In sectors like food and pharma, hygiene is crucial. A well-designed Gyro Screen ensures that operations remain dust-free, noise-free, and compliant with industry safety standards.

Energy-Efficient and Low Maintenance

Thanks to advances in motor and design technology, Vibro Sifters consume minimal energy while offering continuous operation for extended hours. Most quality machines today, including those from Invoit Plast Machinery PVT Ltd, are built with stainless steel bodies and long-lasting motors, making them low-maintenance and durable for tough industrial environments.

Invoit Plast Machinery PVT Ltd – Best Gyro Screens Manufacturer in India

When searching for the best Gyro Screen Manufacturer in India, Invoit Plast Machinery PVT Ltd is a name trusted by industries across the country. With a strong reputation for innovation, durability, and performance, Invoit Plast delivers a range of Gyro Screen Machines tailored for industrial screening requirements.

The company focuses on precision-engineered gyro screens that ensure:

- High throughput rates

- Smooth operation with minimal vibration

- Compact design for space-saving installation

- Customization options to fit specific industry needs

Their machines are ideal for companies in the plastic recycling industry, pharmaceutical production, chemical processing, and many other fields looking for robust and efficient screening solutions.

Key Benefits of Using a Gyro Screen Machine

A gyro screen machine offers numerous benefits that improve the overall processing workflow:

- High Accuracy: Accurately classifies materials into different grades.

- Fast Operation: Reduces processing time by performing continuous, high-speed screening.

- Clean Output: Removes impurities and oversize particles from the final product.

- Scalable Design: Available in sizes and configurations suitable for small workshops or large-scale production plants.

- Easy Maintenance: Designed with simple parts for quick cleaning and part replacement.

The Importance of Choosing the Right Gyro Screen

While Gyro Screens are effective across industries, their performance largely depends on choosing the right machine and right mesh size for your application. Here are a few factors that must be considered:

- Material Characteristics: Powder, slurry, granule, or fiber—all require different mesh specifications.

- Required Throughput: Machines come in varying capacities. Oversizing or undersizing can lead to inefficiency.

- Application Type: Whether your process requires de-dusting, de-watering, or grading determines the screen design.

This is where trusted manufacturers like Invoit Plast Machinery PVT Ltd make a difference by offering expert guidance and customization support to match your industry needs.

Applications of Gyro Screens in the Plastic Industry

In plastic manufacturing and recycling, Gyro Screens for plastic granules or plastic powder screening have become standard equipment. They help ensure the final product is free from contaminants, which is critical when creating high-quality end products like plastic pipes, sheets, injection moldings, or films.

Whether screening HDPE, LDPE, PVC, or PET, gyro screens make sure the material is sorted correctly for further processing or packaging. Their fast throughput and robust separation help streamline plastic production lines.

Latest Technological Advancements

With increasing demand for automation and efficiency, modern gyro screen machines now integrate with:

- PLC-based controls

- Dust collection systems

- Automatic mesh cleaning

- Energy-saving motors

These technological upgrades enhance performance and make these machines suitable for 24×7 industrial operations.

Final Thoughts

In an era of high-speed production and quality-first manufacturing, Gyro Screens have emerged as indispensable tools in industrial processing. They enable precise separation, minimize contamination, and reduce operational downtime. Whether you’re running a plastic processing plant or a pharmaceutical production unit, investing in a high-performance Gyro Screen Machine can significantly improve your workflow and product quality.

When choosing a reliable solution, Invoit Plast Machinery PVT Ltd stands out as the best Gyro Screen Manufacturer in India, offering durable, efficient, and customizable machines designed to meet diverse industrial needs.

FAQs

A Gyro Screen Machine is a type of vibratory screening equipment that uses circular motion to separate materials based on particle size. It works by vibrating a screen or mesh through which materials pass, allowing the desired particle sizes to be filtered out efficiently.

Gyro Screens are used across multiple industries including plastics, food processing, pharmaceuticals, chemicals, minerals, ceramics, and recycling. In particular, they are essential in the plastic industry for separating granules and powders during recycling or production.

Some key benefits include high screening accuracy, multi-deck separation, continuous operation, minimal maintenance, dust-free performance, and energy efficiency. They also help improve product consistency and reduce material wastage.

Yes, most manufacturers—including Invoit Plast Machinery PVT Ltd, a leading Gyro Screen manufacturer in India—offer customization in size, mesh design, material grade, and number of decks to match industry-specific requirements.

Absolutely. With the correct screen configuration and motor settings, Gyro Screens can handle both dry powders and wet slurries, making them highly versatile across different processing needs.

Selecting the right Gyro Screen depends on your material type, desired throughput, required particle size, and environmental conditions. Consulting with a reputable manufacturer like Invoit Plast Machinery PVT Ltd ensures the ideal match for your industrial processing needs.

The terms are often used interchangeably. However, a Vibro Sifter usually refers to a smaller-scale unit used in pharmaceuticals or food, while a Gyro Screen is typically a larger, more industrial-grade version used in plastics, chemicals, and minerals.

In plastic recycling, Gyro Screens help in removing dust, oversized particles, or contaminants from plastic granules or powder. This ensures cleaner, more uniform recycled materials suitable for reuse in manufacturing.

Yes, most modern Gyro Screens are built with user-friendly designs that allow for easy cleaning, screen replacement, and lubrication, making maintenance simple and cost-effective.

Invoit Plast Machinery PVT Ltd is one of the best Gyro Screen manufacturers in India, known for producing high-quality, durable, and performance-driven machines tailored for various industrial applications, especially in the plastic processing and recycling sector.