Top 5 Benefits of Using a PVC Pulverizer Machine in Plastic Recycling

In today’s environmentally-conscious manufacturing world, the plastic recycling industry plays a key role in reducing waste and promoting sustainable production. One essential machine driving this transformation is the PVC Pulverizer. This powerful piece of equipment helps transform discarded plastic products into fine plastic powder that can be reused in multiple applications. Whether you’re running a plastic processing plant or involved in the recycling business, a PVC pulverizer machine can significantly optimize your operations.

Let’s explore the top five benefits of using a PVC Pulverizer Machine in plastic recycling—and why investing in the right model can make all the difference.

Efficient Size Reduction for Reusable Material

A major benefit of using a PVC Pulverizer is its ability to reduce plastic materials into fine powder form quickly and efficiently. Pulverizers are specifically designed to process thermoplastics like PVC (Polyvinyl Chloride), HDPE, LDPE, LLDPE, and other rigid or soft plastic materials. They use high-speed rotors to grind plastic scraps into uniform powder, which can be reused in compounding, extrusion, or molding processes.

This fine pulverization ensures that the recycled material retains quality and is suitable for a wide range of industrial applications, including plastic pipe manufacturing, profiles, fittings, sheets, and even plastic flooring. The consistent particle size produced by a plastic pulverizer machine ensures compatibility with downstream processes and helps maintain a uniform product output.

Cost Savings Through Material Reuse

Recycling plastic using a PVC pulverizer helps businesses drastically cut down their raw material expenses. Instead of purchasing new PVC resin or plastic pellets, manufacturers can simply reuse the pulverized plastic powder produced from scrap material. Over time, this results in substantial cost savings, especially for large-scale production facilities.

By incorporating pulverizers into their recycling workflow, plastic processors can recover value from post-industrial or post-consumer plastic waste, reducing their dependence on virgin materials. This economic advantage is particularly important in industries where profit margins are tight, and sustainable practices are becoming a competitive necessity.

Contribution to Environmental Sustainability

One of the most important long-term benefits of using a plastic pulverizer machine is its positive environmental impact. With the rising concern over plastic pollution, businesses are under pressure to adopt greener production methods. A PVC pulverizer supports this goal by enabling companies to recycle and reuse plastic waste that would otherwise end up in landfills or oceans.

By turning plastic scraps into reusable powder, pulverizers help reduce plastic waste, lower carbon emissions, and minimize energy consumption associated with producing new plastic. This not only boosts your company’s environmental credibility but also helps meet local and global sustainability standards.

Moreover, customers are increasingly choosing brands that value eco-friendly practices. A well-implemented recycling system supported by pulverizer machines can enhance your business reputation and meet customer expectations for sustainable products.

Increased Production Efficiency and Flexibility

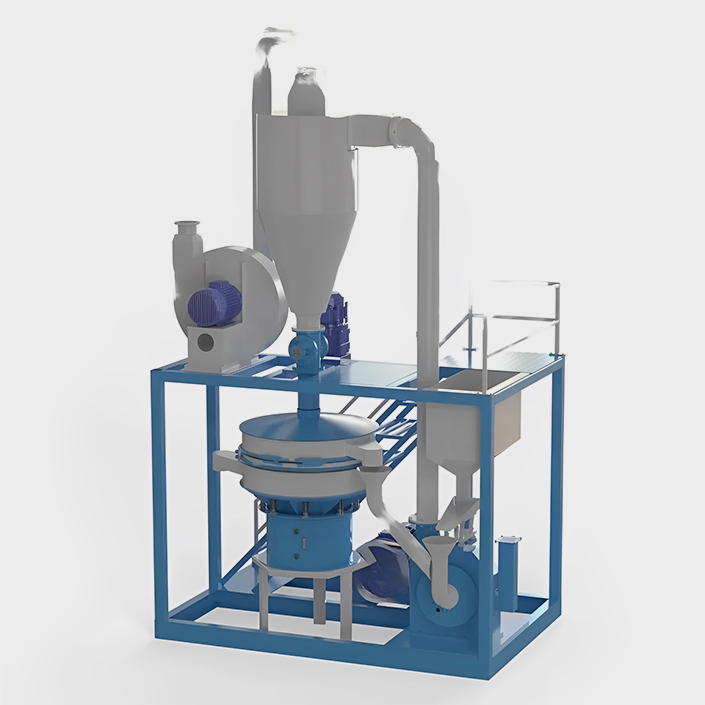

A PVC Pulverizer machine is designed for speed, precision, and flexibility. Modern machines come with advanced features such as auto feeding, temperature control, and adjustable blade settings that allow users to customize particle size and production speed. This level of control ensures smooth operations and minimal downtime.

The compact design of many pulverizers also means they require less floor space, making them ideal for small workshops as well as large factories. Operators can quickly switch between materials or product batches without major reconfiguration. The ease of operation, fast setup, and minimal maintenance make pulverizers a smart investment for companies looking to streamline their recycling and production process.

Additionally, when integrated into a complete plastic recycling system, PVC Pulverizers can significantly increase the overall output of a plant. They ensure that recycled plastic materials are processed faster and more uniformly, reducing bottlenecks and improving throughput.

High Return on Investment (ROI)

Investing in a PVC pulverizer machine is not just an expense—it’s a strategic decision that offers excellent returns. The long-term financial benefits, including savings on raw material costs, reduced waste management expenses, and improved product quality, make it a profitable choice for many plastic manufacturing and recycling businesses.

Moreover, the demand for recycled plastic products is steadily growing across industries. With governments encouraging circular economy practices and customers preferring eco-friendly goods, having a PVC pulverizer puts your business at the forefront of sustainable innovation.

And when the machine is sourced from a reliable manufacturer, it ensures durability, consistent performance, and minimal operational issues. That’s why choosing the right equipment partner is as important as selecting the right machine.

Why Choose Invoit Plast Machinery Pvt. Ltd. for Your PVC Pulverizer?

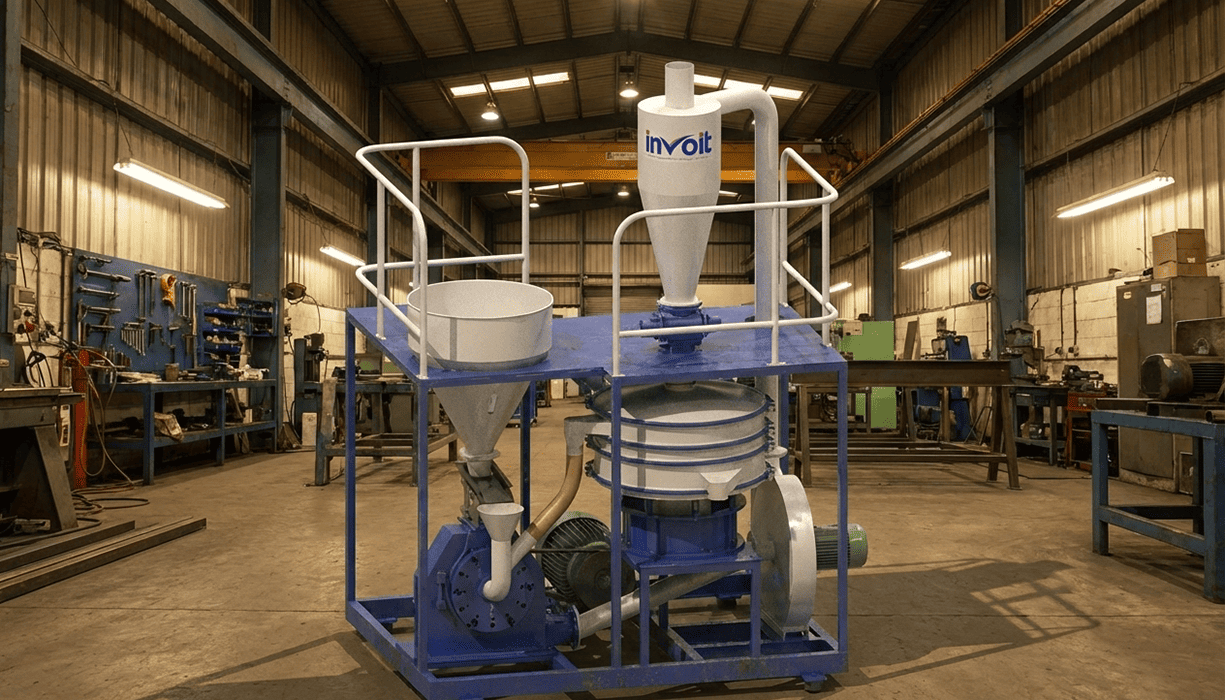

When it comes to investing in a high-quality PVC Pulverizer, reliability, performance, and service are key factors. Invoit Plast Machinery PVT Ltd stands out as the best PVC Pulverizer Machine manufacturer in India, trusted by plastic processors across the country.

With a commitment to cutting-edge technology, energy-efficient design, and customer-focused support, Invoit Plast offers a wide range of pulverizer solutions tailored to your specific needs. Whether you require a machine for rigid PVC, soft PVC, or other thermoplastics, Invoit’s machines deliver superior performance, precision, and productivity.

From single machine supply to complete plastic recycling systems, Invoit Plast provides end-to-end support—from installation and commissioning to after-sales service and spare parts.

If you’re looking to boost your recycling efficiency and reduce production costs, Invoit plastic pulverizer machines are the ideal solution. Their rugged design, low maintenance requirements, and user-friendly features make them a long-term asset for any plastic processing unit.

Final Thoughts

In an era where sustainable practices and resource efficiency define business success, the role of a PVC Pulverizer machine in plastic recycling cannot be overstated. It not only helps reduce plastic waste but also delivers strong financial and operational benefits.

To summarize, the top five benefits of using a PVC pulverizer include:

- Efficient size reduction of plastic waste

- Significant cost savings by reusing material

- Contribution to environmental sustainability

- Enhanced production flexibility and speed

- High return on investment

By integrating a pulverizer into your recycling system, you’re not just choosing better machinery—you’re choosing a better future for your business and the planet.

And when you choose a machine from Invoit Plast Machinery PVT Ltd, you’re choosing a partner committed to excellence, innovation, and sustainability.

FAQs

A PVC Pulverizer Machine is used to grind rigid and soft PVC plastic scraps into fine powder, which can be reused in various plastic manufacturing processes such as compounding, extrusion, and injection molding.

The pulverizer reduces waste plastic into reusable powder form, making it easier to recycle and repurpose the material. This process supports cost savings and promotes environmental sustainability.

Yes, many plastic pulverizer machines are designed to process other thermoplastics like HDPE, LDPE, PP, and LLDPE, depending on the blade and motor specifications.

Key benefits include efficient material size reduction, cost-effective recycling, environmental benefits, improved production flexibility, and high return on investment.

Invoit Plast Machinery Pvt. Ltd. is one of the best PVC Pulverizer Machine manufacturers in India, known for delivering high-performance, durable, and energy-efficient machines with excellent customer support.

Yes, the fine powder produced is suitable for most applications like pipe manufacturing, profiles, flooring, and other plastic components, depending on the material quality and specifications.

Regular cleaning, blade sharpening or replacement, lubrication, and motor inspections are crucial for maintaining machine performance and extending its lifespan.