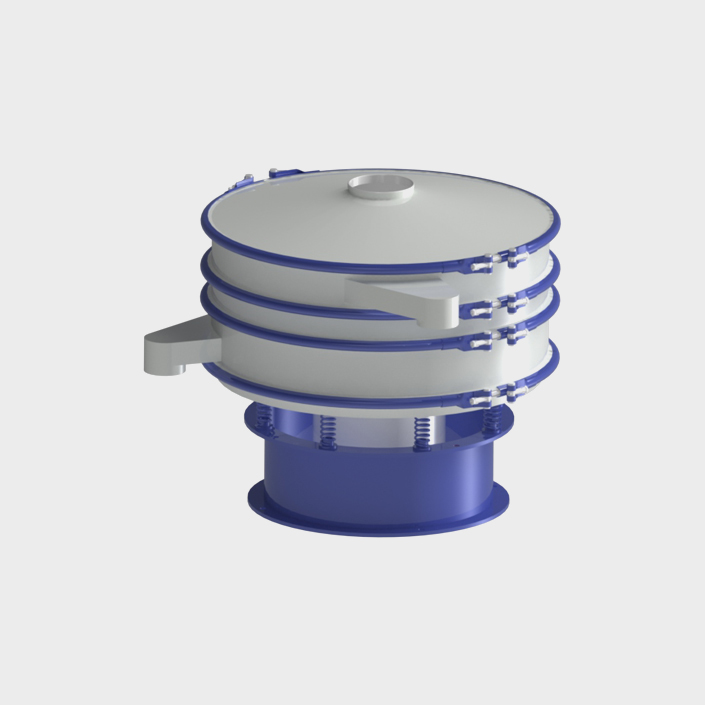

Vibro Screen

Vibro Screen

Invoit Plast Machinery Pvt. Ltd. is a trusted manufacturer and exporter of high-quality Vibro Screens, designed for precision screening and separation of bulk materials in various industries. Our vibro screen machines are engineered to deliver high efficiency, accurate grading, and reliable performance, ensuring that materials are processed smoothly and effectively.

Vibro screens, also known as vibrating screens or gyro screens, use advanced gyratory motion to achieve superior screening, grading, and separation. These machines are perfect for removing impurities, classifying materials, and ensuring uniform particle size distribution across industries such as food, pharmaceuticals, plastics, chemicals, minerals, and more.

Why Choose Our Vibro Screens?

- Superior Screening Performance: Our Vibro Screens are designed to provide precise material separation, eliminating oversized or undersized particles efficiently.

- High Efficiency & Low Maintenance: With a durable design and low power consumption, our machines ensure cost-effective operation with minimal downtime.

- Customizable Configurations: Available in single, double, and multi-deck options, our Vibro Screens can be tailored to specific industry requirements.

- Dust-Free Operation: The enclosed structure minimizes dust contamination, ensuring a clean and safe working environment.

- Robust & Hygienic Design: Constructed with stainless steel or mild steel, our screens comply with industry standards for food and pharmaceutical applications.

Applications of Vibro Screen

Our Vibro Screen Machines are widely used in:

- Food & Beverage Industry

- Screening of spices, flour, sugar, salt, and dairy products

- Removal of unwanted particles in food powders and grains

- Pharmaceuticals & Chemicals

- Separation of powders, granules, and liquid solutions

- Ensuring purity in chemical formulations

- Plastic & Polymer Industry

- Screening of plastic granules, resin, and masterbatch

- Removal of dust and oversize particles

- Minerals & Metal Industry

- Grading and filtering of metal powders, minerals, and ceramic materials

- Fine particle separation in mining operations

- Agricultural & Fertilizer Industry

- Screening of seeds, fertilizers, and animal feed

- Removal of broken and oversized grains

Key Features of Our Vibro Screen

- Highly Efficient Gyratory Motion – Ensures precise material separation with minimal screen blinding.

- Available in Multiple Decks – Choose from single, double, or triple-deck configurations to suit your application.

- Easy to Clean & Maintain – Tool-free disassembly allows for quick cleaning and maintenance.

- Energy-Efficient Operation – Designed to consume less power while delivering maximum output.

- Customizable Screen Mesh – Available in different mesh sizes to suit your material processing needs.

- Low Noise & Vibration-Free Design – Ensures quiet operation with minimal impact on the working environment.

Technical Specifications

- Material Options: Stainless Steel 304/316, Mild Steel

- Screen Diameter: Available in 600mm, 900mm, 1200mm, 1500mm, and 1800mm

- Motor Power: Energy-efficient vibratory motors

- Decks: Single / Double / Triple deck configurations

- Applications: Dry, Wet, and Liquid Screening

Why Choose Invoit Plast Machinery Pvt Ltd?

At Invoit Plast Machinery Pvt. Ltd., we take pride in delivering high-performance screening solutions that enhance production efficiency and product quality. With years of expertise in manufacturing Vibro Screens, we offer:

- Precision-engineered machines with superior durability

- Custom-built solutions to meet industry-specific requirements

- Reliable after-sales support for installation, training, and maintenance

- Competitive pricing with the best value for your investment