What Is a High Speed Mixer Machine? Features, Benefits & Applications

In the world of plastic manufacturing and recycling, efficiency, consistency, and quality are non-negotiable. Every stage of production needs precision, especially during the blending and mixing of raw materials. One vital equipment that plays a crucial role in ensuring optimal performance and output is the High Speed Mixer Machine. This specialized equipment is designed to rapidly mix, blend, and prepare raw plastic materials for further processing.

Whether you’re in plastic extrusion, injection molding, or recycling, understanding how a High Speed Mixer Machine works—and why it matters—can help you achieve better productivity and product quality. Let’s explore this versatile machine in detail, along with its features, benefits, and practical applications in industrial plastic processing.

Understanding What a High Speed Mixer Machine Is

A High Speed Mixer Machine is an industrial mixing unit used to blend plastic raw materials at a high rotation speed. These machines are primarily employed in the plastics industry to mix PVC, LDPE, HDPE, and other polymer-based resins with additives, stabilizers, pigments, and lubricants. High-speed rotation creates frictional heat, allowing the material to become partially softened—enabling better dispersion and mixture uniformity.

These machines are a popular choice for pre-processing materials before extrusion, calendaring, or granulation. Thanks to their design, high efficiency, and consistency, they have become essential in modern plastic product manufacturing.

How Does a High Speed Mixer Machine Work?

The working mechanism of a High Speed Mixer Machine is relatively straightforward but highly effective. It features a stainless-steel mixing container, rotating blades, and a high-power motor. As the motor drives the blades at very high speeds (typically between 1,000 to 3,000 RPM), the plastic granules and additives inside are thrown outward by centrifugal force.

The intense motion and friction result in a rapid and uniform mixture of all components. This frictional heat slightly elevates the temperature, softening the material and ensuring better dispersion of additives like stabilizers, plasticizers, or pigments. The final result is a well-mixed, semi-dried compound ready for further processing.

Key Features of High Speed Mixer Machines

A High Speed Mixer Machine offers a variety of innovative features that support industrial-scale mixing operations. Let’s examine the most notable features that make this machine a top choice in plastic processing plants:

High-Speed Performance

The core advantage lies in its ability to mix at extremely high speeds, reducing mixing time drastically compared to conventional mixers.

Superior Homogenization

High rotational velocity ensures thorough dispersion of additives, pigments, and other components into the plastic resins.

Durable Construction

Manufactured using high-grade stainless steel or alloy components, these mixers can withstand high stress, corrosion, and chemical exposure.

Precision Temperature Control

Some models include integrated temperature controls or jacketed chambers to maintain optimal mixing temperatures for sensitive materials.

Compact and Efficient Design

Despite their powerful performance, many High Speed Mixer Machines have a compact footprint and ergonomic design suitable for space-limited production units.

Easy Cleaning and Maintenance

Smooth surfaces and detachable components make the machine easier to clean, thereby reducing downtime between batches.

Benefits of Using a High Speed Mixer Machine

The decision to use a High Speed Mixer Machine offers several operational and economic advantages, especially for industries focused on quality and efficiency. Here are the major benefits:

Enhanced Productivity

The fast mixing cycle allows manufacturers to increase output, reduce cycle times, and meet higher production demands without compromising quality.

Energy-Efficient Operation

Modern mixers are optimized for reduced energy consumption despite their high rotational speed, making them cost-effective in the long run.

Consistent Output Quality

Thanks to uniform mixing, the final product’s properties—such as color, strength, and stability—remain consistent across batches.

Versatility

These machines can handle a variety of materials including virgin resins, recycled plastics, additives, and fillers—making them suitable for a broad range of plastic processing applications.

Reduced Labor Requirement

The automation features in high-speed mixers simplify operations and reduce the need for continuous manual supervision.

Improved Pre-Processing for Recycling

In plastic recycling applications, especially when using waste Vertical Mixer Machine and Plastic Mixer Machine, high-speed mixing helps refine the feedstock quality and prepares it for efficient reuse.

Applications of High Speed Mixer Machines in Industry

High Speed Mixer Machines are widely used in various stages of plastic product manufacturing and recycling. Below are the most common applications:

PVC Compound Preparation

Mixing PVC with additives before extrusion or molding requires quick and homogeneous dispersion, which high-speed mixers are designed for.

Plastic Recycling

In recycling units, high-speed mixers are used to prepare shredded plastic waste by blending it with stabilizers or colorants for pelletizing or extrusion.

Masterbatch Production

Creating masterbatches involves intensive blending of pigments and polymers, a task ideally suited for high-speed mixers due to their superior dispersion capability.

Film and Sheet Manufacturing

High-speed mixing ensures that the feedstock for film or sheet production is uniform in composition and moisture-free.

Pipe and Profile Extrusion

For extrusion processes, consistent material quality is critical—achieved through efficient high-speed pre-mixing.

Thermoplastic Processing

Whether it’s LDPE, HDPE, PP, or ABS, high-speed mixers can handle a variety of thermoplastic materials and optimize their processing behavior.

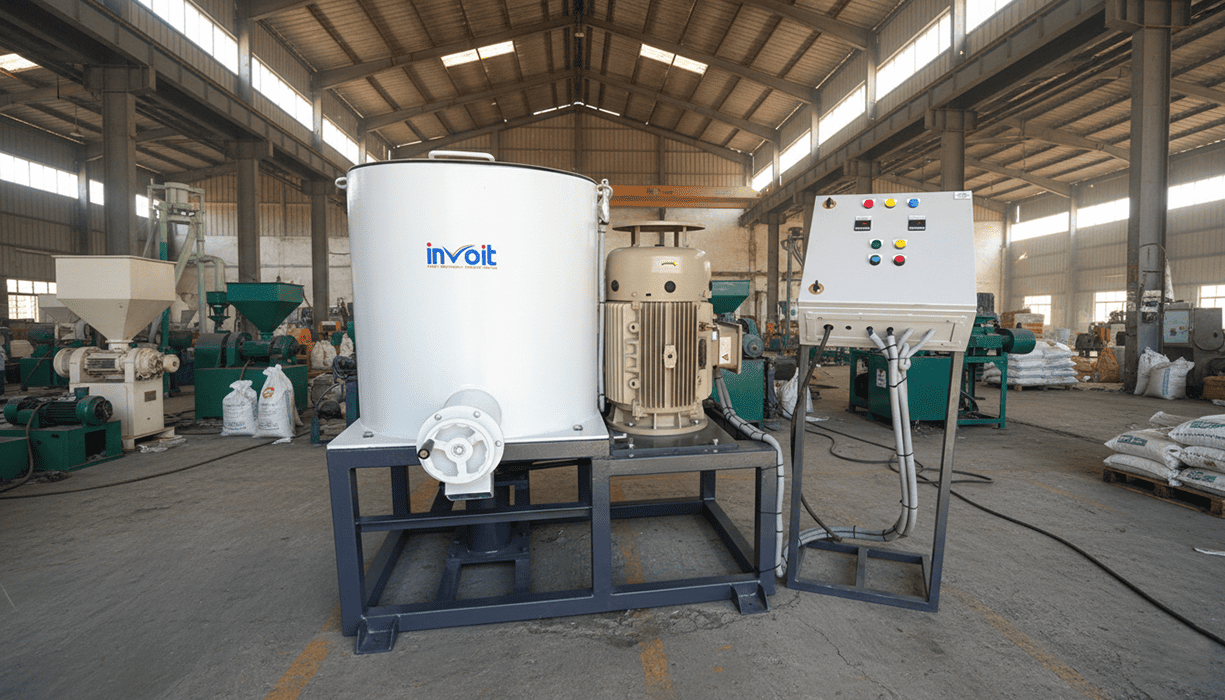

Why Choose Invoit Plast Machinery PVT Ltd?

When selecting the right high-speed mixer machine for your needs, quality, durability, and after-sales support matter. Invoit Plast Machinery PVT Ltd stands out as the best High Speed Mixer Machine manufacturer in India, known for its cutting-edge engineering, customer-centric design, and robust build quality.

Invoit Plast offers a wide range of Plastic Mixer Machines, including waste Vertical Mixer Machines and High Speed Mixer Machines, tailored to meet different industrial requirements. Their machines are trusted by plastic manufacturers and recyclers across India and globally for their efficiency, reliability, and innovative features.

Whether you’re launching a new facility or upgrading your existing setup, Invoit Plast delivers custom solutions with technical support, training, and after-sales service that ensures long-term value.

FAQs

A High Speed Mixer Machine is used to mix plastic resins with additives, stabilizers, and pigments at high speeds. It ensures uniform dispersion and pre-heats the materials, preparing them for extrusion, molding, or recycling processes.

These machines can handle a wide range of plastic materials like PVC, LDPE, HDPE, PP, ABS, and recycled plastic flakes. They’re also suitable for dry blending of masterbatches and thermoplastics.

While both mix plastic materials, a High Speed Mixer Machine operates at significantly higher speeds, generating frictional heat and ensuring faster and more uniform blending. A waste Vertical Mixer Machine is slower and primarily used for batch-level vertical mixing of recycled or waste plastics.

Yes, most modern High Speed Mixer Machines are designed to be energy-efficient despite their high-speed operation. They offer low power consumption per output unit, making them cost-effective over time.

Invoit Plast Machinery PVT Ltd is recognized as one of the best High Speed Mixer Machine manufacturers in India. They provide robust, durable, and high-performance mixers for both virgin and recycled plastic processing.

Absolutely. High Speed Mixers are commonly used in recycling plants to blend additives with shredded plastic waste, improving the quality and consistency of the recycled pellets or granules.