What is a Plastic Crusher Machine? A Complete Guide for Industries

In today’s world, plastic waste has become one of the most significant environmental concerns. With millions of tons of plastic being produced and discarded each year, industries and businesses are actively seeking sustainable solutions to manage plastic waste efficiently. One of the most effective solutions for plastic waste management is the plastic crusher machine. This machine is a crucial tool in the plastic recycling process, enabling industries to break down plastic waste into smaller, manageable pieces for further recycling or disposal.

Understanding the Plastic Crusher Machine

A plastic crusher machine is a powerful industrial device used to crush and grind plastic materials into smaller granules or powder. It is commonly used in plastic recycling plants, manufacturing units, and waste management facilities to process plastic waste efficiently. The machine comes in various sizes and capacities, depending on the type of plastic material and the required output.

Plastic crushers are essential for reducing the volume of plastic waste, making it easier to transport, store, and recycle. These machines help industries minimize environmental pollution, optimize waste management, and contribute to the circular economy by reusing plastic materials.

How a Plastic Crusher Machine Works

The working principle of a plastic crusher machine is relatively straightforward. The process begins with feeding plastic waste into the machine’s cutting chamber, where rotating blades shred the material into smaller pieces. The crushed plastic is then collected for further processing, such as washing, drying, and melting, to create new plastic products.

Most plastic crushers operate using high-speed rotating blades or knives made of durable materials like stainless steel. These blades effectively cut, shred, and crush plastic waste, reducing it to fine granules that can be repurposed for manufacturing new plastic products.

Types of Plastic Crusher Machines

There are several types of Plastic Scrap Grinder Machine available in the market, each designed for specific applications. Some of the most common types include:

- Small Plastic Recycling Machines: These compact crushers are ideal for small-scale businesses and startups that need an affordable solution for plastic waste recycling. They are designed for moderate plastic crushing needs and can handle different types of plastic waste efficiently.

- Waste Plastic Crusher Machines: These machines are built for large-scale industrial applications, capable of processing high volumes of plastic waste. They are commonly used in plastic manufacturing units, recycling plants, and waste management facilities.

- Heavy-Duty Industrial Plastic Crushers: Designed for robust industrial use, these machines can crush thick plastic materials such as PVC pipes, plastic drums, and industrial plastic sheets.

- Shredders with Built-in Crushers: These machines combine shredding and crushing functions to enhance the recycling process. They are perfect for handling mixed plastic waste, ensuring a uniform size output.

Key Features of a High-Quality Plastic Crusher Machine

A plastic waste recycling machine should possess certain essential features to ensure efficiency and durability. Some of the key features include:

- High-speed Rotating Blades: Sharp and durable blades ensure fast and efficient plastic crushing.

- Energy Efficiency: Low power consumption helps businesses reduce operational costs.

- User-Friendly Controls: Easy-to-operate control panels enhance productivity and minimize downtime.

- Safety Features: Emergency stop buttons, overload protection, and dust collection systems improve workplace safety.

- Versatility: The ability to process different types of plastic materials, such as PET bottles, HDPE containers, and plastic films.

Industries That Benefit from Plastic Crusher Machines

Several industries rely on plastic crusher machines to manage their plastic waste effectively. These industries include:

- Plastic Manufacturing: Companies producing plastic goods use crushers to recycle production waste and reduce material costs.

- Recycling Plants: These facilities use plastic recycling machines to process waste into reusable materials.

- Packaging Industry: The packaging sector benefits from crushing plastic wraps, bottles, and containers for reuse.

- Automobile Industry: Used plastic parts from vehicles can be crushed and repurposed for manufacturing new components.

- Textile Industry: Some fabrics contain plastic-based fibers, which can be recycled using plastic crushers.

Benefits of Using a Plastic Crusher Machine

A plastic waste recycling machine offers numerous advantages, making it an indispensable asset for industries. Some of the benefits include:

- Reduces Plastic Waste Volume: Plastic crushers help in minimizing the bulkiness of plastic waste, making it easier to store and transport.

- Improves Recycling Efficiency: Crushed plastic materials are easier to process, enhancing the efficiency of recycling plants.

- Cost-Effective Waste Management: Businesses can save money by reusing plastic materials instead of purchasing new raw materials.

- Eco-Friendly Solution: Recycling plastic waste helps in reducing environmental pollution and promotes sustainability.

- Enhances Workplace Cleanliness: Using a crusher machine ensures a tidy and organized workspace, reducing the clutter of plastic waste.

Factors to Consider When Buying a Plastic Crusher Machine

Choosing the right plastic crusher machine depends on several factors, including:

- Capacity and Output: Determine the volume of plastic waste your business needs to process.

- Blade Quality: High-quality stainless steel blades last longer and provide efficient crushing.

- Energy Consumption: Look for machines with low energy requirements to save operational costs.

- Safety Features: Ensure the machine has protective measures like emergency stops and automatic shutdown.

- Machine Size and Portability: Consider the available space in your facility before purchasing a machine.

Maintenance Tips for Plastic Crusher Machines

To ensure long-lasting performance, regular maintenance of a plastic recycling machine is essential. Here are some key maintenance tips:

- Regular Blade Sharpening: Keep the blades sharp for efficient crushing.

- Cleaning the Machine: Remove plastic residue to prevent clogging and overheating.

- Lubrication of Moving Parts: Proper lubrication reduces wear and tear.

- Inspection for Wear and Damage: Regularly check for worn-out components and replace them as needed.

- Proper Storage: Keep the machine in a dry and dust-free environment when not in use.

Future of Plastic Recycling and Crusher Machines

With increasing awareness of environmental sustainability, the demand for plastic recycling machines is expected to grow. Governments and industries worldwide are implementing stricter regulations for plastic waste disposal, leading to a rise in the adoption of plastic crusher machines. Innovations such as AI-powered crushers, automated sorting systems, and energy-efficient designs are further improving the efficiency of plastic waste management.

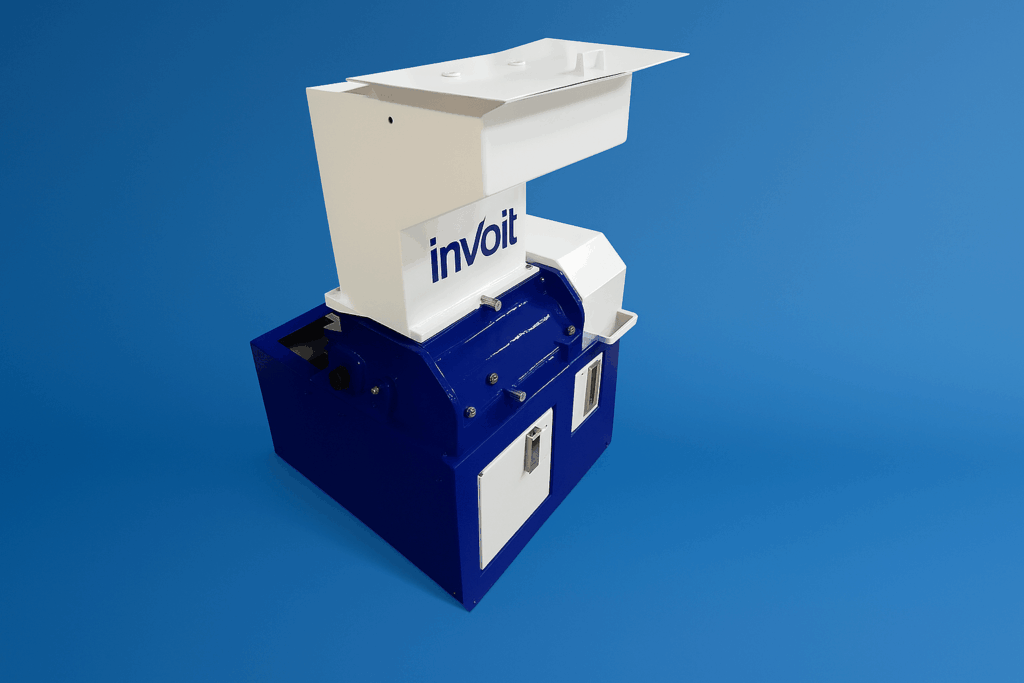

Invoit Plast: Best Plastic Crusher Machine Manufacturer in India

When it comes to high-quality and reliable plastic crusher machines, Invoit Plast stands out as the leading manufacturer in India. The company provides top-of-the-line plastic recycling machines designed for efficiency, durability, and eco-friendly operations. Whether you need a small plastic recycling machine for your startup or an industrial-grade crusher for large-scale operations, Invoit Plast offers the best solutions tailored to your needs.

Final Thoughts

A plastic crusher machine is an essential tool for industries looking to manage plastic waste efficiently. From reducing waste volume to promoting recycling, these machines play a critical role in sustainable plastic waste management. With various types and advanced features available, businesses can choose the right plastic recycling machine to suit their needs. Investing in a quality plastic crusher machine from a trusted manufacturer like Invoit Plast ensures efficiency, durability, and cost-effectiveness. As industries continue to prioritize eco-friendly solutions, the use of plastic crushers will remain a key component of waste management and recycling efforts.