What is a Vibro Screen? A Complete Guide to Its Working & Applications

In the modern industrial landscape, efficient material separation and screening play a crucial role in ensuring high-quality production. Among the most advanced screening solutions available today is the Vibro Screen. This high-performing vibrating screen system is widely used across multiple industries for sorting, grading, and filtering materials. Whether it’s the food, pharmaceutical, plastic, or chemical industry, Vibro Screens are an essential part of their processing units.

This guide will cover everything you need to know about Vibro Screens, including their working principles, key applications, benefits, and why Invoit Plast is the best Vibro Screen manufacturer in India.

Understanding Vibro Screen: An Overview

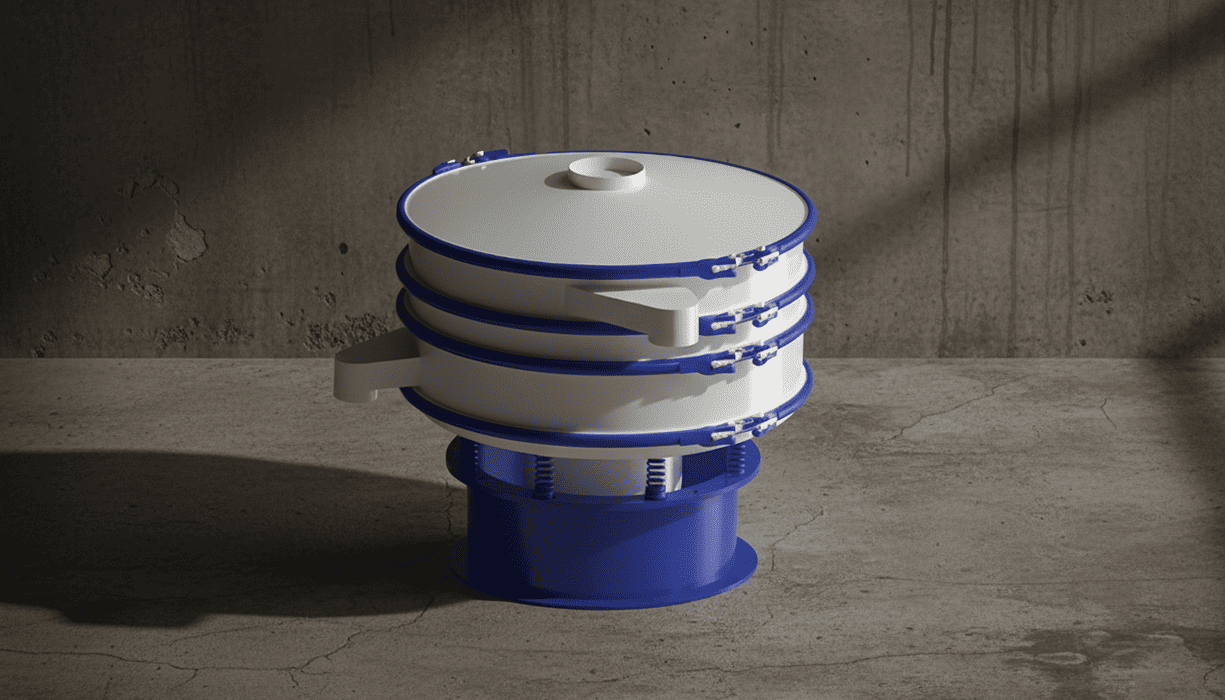

A Vibro Screen, also known as a Vibrating Screen Separator, is a high-precision screening machine designed for separating materials based on size, shape, and consistency. This machine operates on the principle of gyratory motion, ensuring smooth and efficient screening. The vibrating motor generates high-frequency vibrations, which cause the material to move across different mesh screens, allowing only the desired particles to pass through while larger or unwanted particles are removed.

How Does a Vibro Screen Work?

The working mechanism of a Vibro Screen is based on vibratory motion, which is achieved using an eccentric motor or electromagnetic drive. Here’s a step-by-step breakdown of its working principle:

- Material Feeding – The raw material is fed onto the screening mesh via a feed inlet.

- Vibratory Motion – The motor generates vibrations that move the material in a circular or linear motion.

- Screening Process – The material passes through multiple mesh layers of different sizes, allowing for separation based on particle size.

- Fine & Coarse Separation – The fine particles pass through the mesh, while oversized particles are discharged separately.

- Final Collection – The separated material is collected for further processing or packaging.

This seamless process makes Vibro Screens an ideal choice for industries that require high precision and efficiency in material separation.

Applications of Vibro Screen in Various Industries

Vibro Screens are used in a wide range of industries due to their high efficiency and versatility. Let’s take a look at some of the key industries where they play a significant role:

- Plastic & Polymer Industry

Vibro Screens are extensively used in plastic and polymer processing plants for grading and recycling plastic granules, removing impurities, and ensuring uniform size distribution. They help in improving the quality of plastic products by removing unwanted contaminants.

- Food & Beverage Industry

In the food industry, Vibro Screens play a crucial role in filtering, grading, and screening ingredients such as flour, sugar, spices, and grains. They help maintain hygiene standards and ensure uniform particle size in food processing units.

- Pharmaceutical Industry

Precision is key in pharmaceutical manufacturing. Vibro Screens help in removing foreign particles from powders, ensuring accurate formulation and maintaining compliance with health and safety standards.

- Chemical Industry

In chemical plants, Vibro Screens are used for filtering and classifying chemicals like powders, pigments, and resins. They help in preventing contamination and improving the overall quality of chemical products.

- Paper & Pulp Industry

Vibro Screens assist in filtering pulp and separating impurities during the paper manufacturing process. They enhance the quality of paper by removing unwanted particles efficiently.

- Metal & Mineral Processing

In metallurgy and mining, Vibro Screens help in separating different grades of ore and minerals. They ensure proper classification and sizing of metal particles, aiding in further processing.

- Waste Management & Recycling

Vibro Screens are essential in the waste recycling industry for sorting recyclable materials, filtering unwanted debris, and improving the efficiency of recycling processes.

Key Benefits of Using Vibro Screens

Vibro Screens offer multiple advantages that make them a preferred choice across various industries. Here are some of the key benefits:

- High Screening Efficiency – Ensures precise separation of materials, enhancing overall production quality.

- Minimal Maintenance – Requires low maintenance due to its robust design and high-quality construction.

- Energy Efficient – Operates with minimal energy consumption, making it a cost-effective solution.

- Customizable Designs – Available in various sizes and mesh configurations to suit different industrial needs.

- Improved Productivity – Helps streamline the screening process, leading to higher output and efficiency.

- Noise-Free Operation – Designed to operate with minimal noise, ensuring a safe and comfortable working environment.

Why Choose Invoit Plast for Vibro Screens?

When it comes to high-quality Vibro Screens, Invoit Plast stands out as the best manufacturer in India. Here’s why:

- Advanced Engineering – Invoit Plast uses state-of-the-art technology to design Vibro Screens that offer maximum efficiency and durability.

- Custom Solutions – Offers customized screening solutions tailored to specific industrial requirements.

- Quality Assurance – Each machine undergoes rigorous testing to ensure optimal performance and longevity.

- Competitive Pricing – Provides high-quality Vibro Screens at affordable prices, making them accessible to businesses of all sizes.

- Excellent Customer Support – Ensures quick response times and dedicated support to assist customers with their needs.

A Vibro Screen is an indispensable tool for industries that require efficient material screening and separation. Its high efficiency, durability, and precision make it the preferred choice in industries like plastic processing, food, pharmaceuticals, chemicals, and waste management.

For businesses looking for the best Vibro Screen manufacturer in India, Invoit Plast is the top choice, offering high-quality, durable, and customized solutions for all screening needs. Investing in the right Vibro Screen can significantly enhance production efficiency and ensure superior product quality.