Which Plastic Crusher Is Right for Your Production Line?

In today’s fast-paced plastic manufacturing and recycling industries, having the right equipment is no longer a luxury—it’s a necessity. Among the many machines used in plastic processing, the plastic crusher machine stands out as a key player. Whether you’re running a small recycling unit or managing a high-capacity production line, choosing the right plastic crusher can directly affect your output quality, energy efficiency, and overall productivity.

But with multiple crusher types available—each designed for different capacities, materials, and operational needs—how do you decide which plastic crusher is right for your specific production line?

Let’s explore this in detail.

Understanding the Role of a Plastic Crusher Machine

Before selecting the right crusher, it’s important to understand its role in your process. A plastic crusher machine is designed to break down waste or scrap plastic into smaller, manageable granules or flakes. These granules can then be reused for molding, extrusion, or other plastic processing methods.

The crusher handles a wide range of materials including HDPE, LDPE, PET, PVC, PP, and more. It’s a vital piece of equipment in recycling lines, injection molding facilities, extrusion units, and blow molding plants. Choosing the right crusher ensures minimal downtime, maximum throughput, and high-grade regrind quality.

Key Factors That Influence Crusher Selection

When it comes to selecting the best plastic crusher machine for your production line, several key factors come into play. Below are the most crucial ones explained in an easy-to-understand manner.

Type of Plastic Material

The type of plastic you’re processing has a major impact on your choice of crusher. Hard materials like polycarbonate or thick HDPE pipes require powerful crushers with strong blades and heavy-duty motors. Softer materials such as LDPE films or PET bottles can be managed with standard crushing equipment.

Using the wrong crusher for the material type can lead to increased wear and tear, inefficient crushing, and even equipment damage over time.

Output Size Requirements

Different production lines demand different output sizes. For example, if you’re feeding the crushed material directly into an extruder, a uniform granule size is essential. In such cases, choose a crusher with customizable screen sizes or adjustable blade clearance.

Fine grinding models are ideal for applications that require ultra-small particles, whereas coarse crushers are better suited for initial size reduction before secondary processing.

Production Capacity

Whether you’re running a small-scale operation or a high-volume plant, matching the crusher’s throughput capacity with your line requirements is vital. A mismatch can cause bottlenecks, reduced efficiency, or idle time.

Small production setups can go with low to mid-capacity plastic crusher machines, while large facilities should invest in high-capacity models that can handle continuous operations without overheating or jamming.

Blade Design & Material

The blade is the heart of any crusher. Crushers with heavy-duty steel or alloy blades offer better durability, especially when crushing thick or tough plastics. Additionally, the number and arrangement of blades—such as staggered, claw, or flat types—affect how the plastic is cut and how smooth the operation is.

Staggered blades are more energy-efficient and reduce noise, making them perfect for indoor settings or noise-sensitive environments.

Ease of Maintenance

Downtime is costly, so choosing a machine that is easy to clean and maintain can save hours of productivity. Look for features like easily removable screens, quick-open housings, and modular blade assemblies.

Invoit Plast Machinery PVT LTD, for example, designs crushers with user-friendly maintenance in mind, allowing operators to perform cleaning and part replacements with minimal tools and time.

Safety Features

Safety should never be compromised. The right plastic crusher machine must include safety switches, emergency stops, protective guards, and thermal overload protection to ensure operator safety and equipment longevity.

Especially in high-speed or heavy-duty operations, having built-in safety systems is non-negotiable.

Energy Efficiency

A crusher energy consumption can add significantly to operational costs. Opt for energy-efficient machines that come with high-efficiency motors, load sensors, and auto-shutdown features during idle periods. These innovations can significantly reduce your monthly power bills and carbon footprint.

Integration with Existing Line

One often-overlooked aspect is how well the crusher integrates with your current production setup. If you’re using automated conveyors or robotic feeders, ensure the crusher can sync with those systems seamlessly. Some models also offer IoT compatibility and remote diagnostics, which can boost efficiency even further.

Types of Plastic Crusher Machines & Their Applications

There are several types of plastic crusher machines, each with unique applications. Let’s briefly look at the most common ones to help you narrow down your selection.

Standard Plastic Crushers

These are general-purpose crushers suitable for most plastic types including bottles, pipes, sprues, and film. They are ideal for medium-scale operations where materials are relatively uniform.

Heavy-Duty Plastic Crushers

These machines are designed for high-volume, industrial use and can handle rigid plastics, lumps, and even loaded containers. They come with reinforced structures, powerful motors, and wear-resistant components.

If you’re dealing with large chunks of plastic or operate in a 24/7 environment, a heavy-duty plastic crusher machine is a reliable choice.

Silent or Low-Noise Crushers

Perfect for in-house recycling and compact workspaces, silent crushers use sound insulation and vibration dampening to reduce operational noise. These are commonly used in cleanroom environments or where employees work nearby.

Centralized vs. Beside-the-Press Crushers

Centralized crushers are stationed in a common area and handle the waste from multiple machines, while beside-the-press crushers are positioned right next to molding machines for immediate recycling. Choose based on your workflow setup and plant layout.

Why Choosing the Right Manufacturer Matters

Beyond features and specifications, the quality of the plastic crusher machine is heavily influenced by the manufacturer. Reliable manufacturers focus on quality components, precision engineering, and ongoing support.

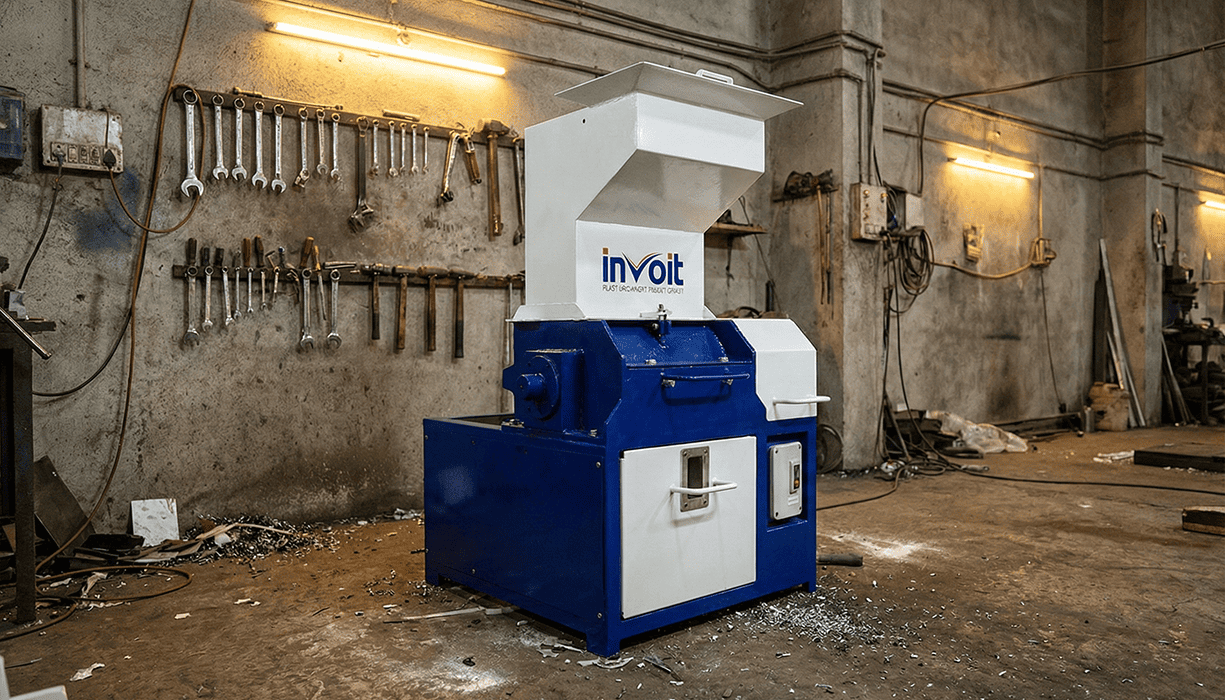

Invoit Plast Machinery PVT LTD stands out as one of the best plastic crusher machine manufacturers in India. With years of experience, a customer-first approach, and world-class engineering, Invoit Plast delivers robust and reliable crushers tailored for all types of production lines.

Their machines are not only built to last but also optimized for energy efficiency, noise reduction, and operational simplicity—making them a favorite among Indian and international manufacturers alike.

Match Your Needs with the Right Crusher

There’s no one-size-fits-all plastic crusher. Your production line’s scale, material type, processing speed, and integration needs should guide your selection. Always consider the long-term cost benefits, not just the initial price tag. A well-chosen plastic crusher machine will pay for itself through improved efficiency, reduced waste, and better-quality output.

If you’re unsure which crusher is best suited for your setup, consult a trusted supplier like Invoit Plast Machinery PVT LTD. Their expertise and tailored solutions can help you identify the ideal crusher for your production line and ensure your operations stay competitive, efficient, and future-ready.

Final Thought

Making an informed choice when selecting a plastic crusher is not just a technical decision—it’s a strategic investment. Go for reliability, efficiency, and long-term performance. And when in doubt, turn to a trusted name in the industry.

Choose Invoit Plast Machinery PVT LTD – The Best Plastic Crusher Machine Manufacturer in India.

FAQs

A plastic crusher machine is used to break down plastic waste or rejected plastic parts into smaller pieces or granules. These crushed plastics can be reused in manufacturing processes such as molding or extrusion, making the machine essential for recycling and reducing plastic waste.

To choose the right plastic crusher, consider factors such as the type of plastic material, required output size, production capacity, blade design, and whether it integrates with your existing machinery. Choosing the right machine ensures smooth workflow, better energy efficiency, and reduced downtime.

Plastic crusher machines can handle a variety of materials including HDPE, LDPE, PP, PET, PVC, ABS, and polycarbonate. The machine you choose should match the hardness and thickness of the plastic you process for optimal performance.

A heavy-duty plastic crusher machine is designed for high-volume, industrial use and can crush thick, rigid plastics like plastic lumps, drums, or loaded containers. In contrast, a standard crusher is ideal for light to medium-duty tasks such as sprues, films, and small bottles.

Yes, in many cases the crushed plastic granules can be directly reused in molding or extrusion processes. However, you may need to clean, sort, or dry the material first, depending on your product requirements.